Overview

Titanium Flanges are known for their outstanding corrosion resistance, excellent strength-to-weight ratio, and biocompatibility. They are widely used in aerospace, marine, chemical processing, desalination, medical implants, and offshore oil & gas industries.

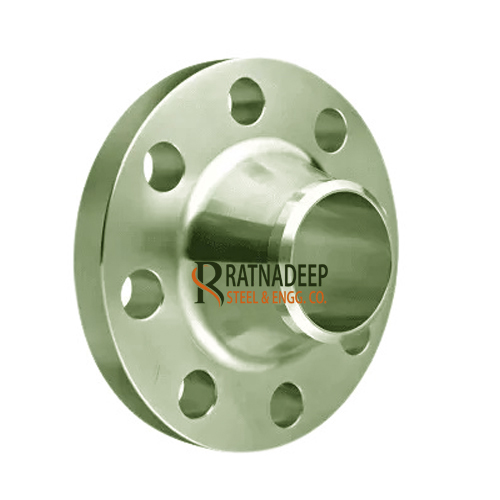

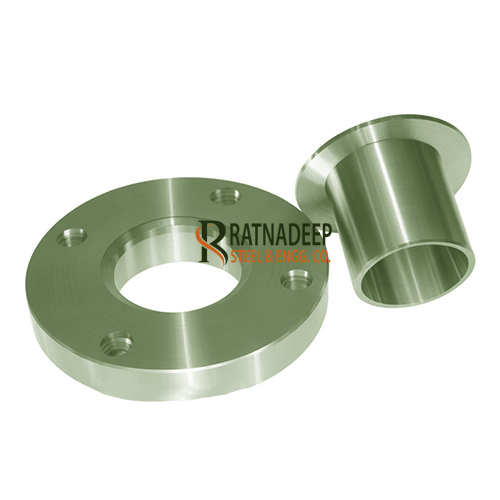

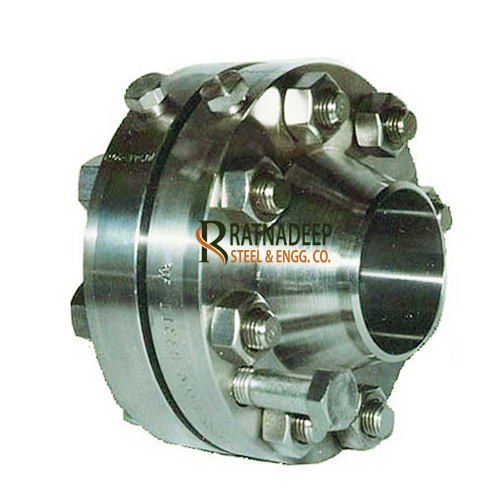

Types of Titanium Flanges

Technical Specifications

| Standard | Size Range | Pressure Rating | Face Type |

|---|---|---|---|

| ASME / ANSI B16.5 & B16.47 | ⅛” to 48” | 150# to 2500# | RF, RTJ |

| DIN | DN10 to DN2000 | PN6 to PN400 | RF, FF |

| Custom | As per client requirements | Upto 20,000 PSI (special alloys) | RF, FF, RTJ |

Material Grades / Alloys Included:

Grade 1, Grade 2, Grade 3, Grade 4, Grade 5 (Ti-6Al-4V),

Grade 7, Grade 9 (Ti-3Al-2.5V), Grade 12 (Ti-0.3Mo-0.8Ni),

Grade 23 (Ti-6Al-4V ELI).

Titanium Grades Comparison

| Grade | Strength | Corrosion Resistance | Applications |

|---|---|---|---|

| Grade 1 | Low | Excellent | Chemical processing, marine |

| Grade 2 | Medium | Excellent | General industrial, desalination |

| Grade 3 | Higher than Grade 2 | Good | Aerospace, marine |

| Grade 4 | Highest of CP Titanium | Good | Aerospace, offshore |

| Grade 5 (Ti-6Al-4V) | Very High | Good | Aerospace, offshore, power generation |

| Grade 7 | Medium | Outstanding (Palladium stabilized) | Chemical processing, reducing acids |

| Grade 9 (Ti-3Al-2.5V) | High | Good | Aerospace tubing, hydraulics |

| Grade 12 (Ti-0.3Mo-0.8Ni) | Medium | Excellent at high temperatures | Marine, heat exchangers |

| Grade 23 (Ti-6Al-4V ELI) | Very High | Good | Medical implants, surgical devices |

Chemical & Mechanical Properties

- Tensile Strength: 240–1000 MPa (depending on grade)

- Yield Strength: 170–880 MPa

- Density: 4.5 g/cm³ (approx. 45% lighter than steel)

- Hardness: 70–350 HB (depending on grade)

- Exceptional resistance to seawater, chlorides, and oxidizing environments

Applications & Industries

Key Features & Benefits

- Lightweight with high strength-to-weight ratio

- Outstanding resistance to seawater & chlorides

- High performance in oxidizing & acidic environments

- Biocompatible (safe for medical applications)

- Excellent weldability & machinability (Grade 2, 5, 9)

Certifications & Quality Assurance

- ISO Certified

- PED & IBR Approved

- Third-party inspection (TPI) available

- Mill Test Certificates (MTC) provided

Frequently Asked Questions

Which Titanium grade is most commonly used for flanges?

Grade 2 is the most widely used due to its balance of strength, corrosion resistance, and weldability.

What’s the difference between Grade 2 and Grade 5 Titanium flanges?

Grade 2 is commercially pure titanium with excellent corrosion resistance, while Grade 5 (Ti-6Al-4V) offers much higher strength, making it ideal for aerospace and offshore industries.

Are Titanium flanges suitable for seawater applications?

Yes, especially Grade 2, Grade 7, and Grade 12 Titanium flanges are highly resistant to seawater and brine, making them perfect for marine and desalination plants.

Request a Quote

Looking for premium Titanium Alloy Gr 1/2/5/9 Flanges in all grades? Get in touch with us today.

Contact Us