What is 904L Stainless Steel?

904L stainless steel is a super austenitic stainless steel grade with exceptional corrosion resistance, particularly in acidic and chloride-containing environments. It contains high levels of chromium, nickel, molybdenum, and copper, making it ideal for applications involving sulfuric acid, phosphoric acid, and other aggressive chemicals. Its superior performance makes it suitable for various industrial applications where maximum corrosion resistance is critical.

904L Stainless Steel

Chromium (Cr)

Nickel (Ni)

Molybdenum (Mo)

Copper (Cu)

Carbon (C) Max

Manganese (Mn) Max

Silicon (Si) Max

Phosphorus (P) Max

Sulfur (S) Max

Nitrogen (N) Max

Iron (Fe)

Types of Stainless Steel 904L Pipes & Tubes

As premier manufacturers in the industry, we specialize in producing both stainless steel 904L seamless pipes & tubes and stainless steel 904L welded pipes & tubes, offering comprehensive solutions for diverse corrosive industrial requirements.

Manufactured from solid billets through an extrusion process, these pipes deliver superior strength and exceptional corrosion resistance in aggressive chemical environments. Seamless construction eliminates weld seams, making them the preferred choice for critical applications involving sulfuric acid, phosphoric acid, and chloride-containing media where welding integrity is paramount under corrosive conditions. Their homogeneous structure ensures maximum resistance to pitting and crevice corrosion.

These pipes provide an economical alternative with availability across a broader spectrum of sizes and dimensions while maintaining excellent corrosion resistance properties. Welded pipes excel in chemical processing systems, pulp and paper industry applications, and seawater environments where reliable welded joints are essential. Their cost-effectiveness makes them ideal for corrosive service projects with budget constraints without compromising chemical resistance and durability in aggressive media.

Specification of Stainless Steel 904L Seamless & Welded Pipes And Tubes

| Specification | Details |

|---|---|

| Stainless Steel Pipe Specification | ASTM B677, A312 / ASME SB677, SA312 |

| SS Tube Specification | ASTM B676, A213, A269 / ASME SB676, SA213, SA269 |

| Pipe Size | 1/8” NB to 24” NB, 1/4” OD to 24” OD sizes |

| Tube Size | 1/2″ OD to 8″ OD |

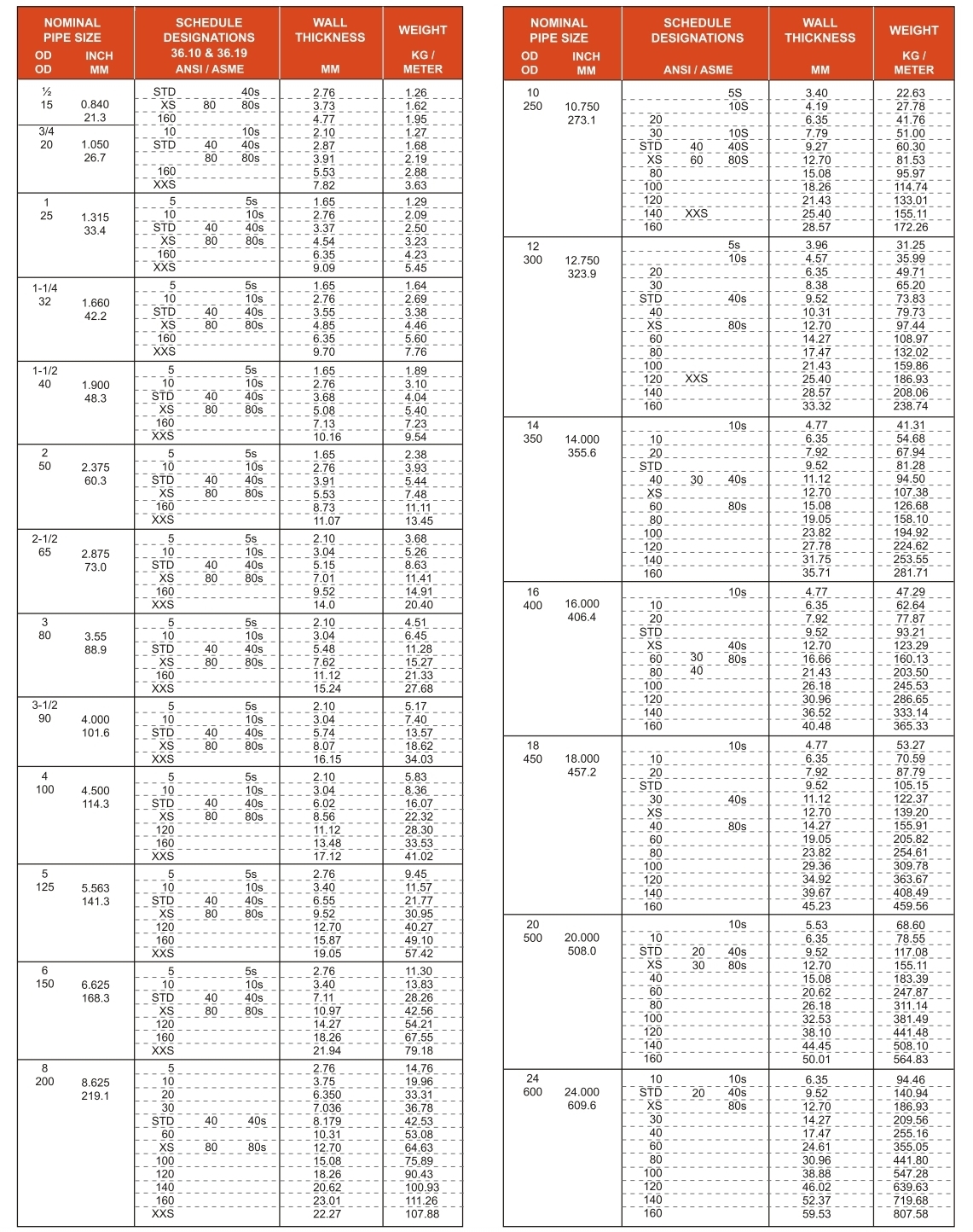

| Thickness Range | 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Type | Seamless / ERW / Welded / Fabricated Pipes |

| Form | Round, Square, Rectangular, Oval, Hydraulic Etc |

| Length | Single Random, Double Random & Required Length |

| End | Plain End, Beveled End, Threaded |

| End Protection | Plastic Caps |

| Outside Finish | 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Inspection, Test Reports | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be manufactured on request |

STAINLESS STEEL PIPE & TUBES SCHEDULE DIMENSIONS WALL THICKNESS, WT./MTR. (KG)

Click to expand ▼

Stainless Steel 904L Pipe Dimensions & Weight Chart

| OD (mm) | WT (mm) | NPS (dn) | Schedule | Weight (kg/m) |

|---|---|---|---|---|

| 13.72 | 1.65 | 1/4″ | 10S | 0.50 |

| 13.72 | 2.24 | 1/4″ | 40S | 0.64 |

| 13.72 | 3.02 | 1/4″ | 80S | 0.81 |

| 17.15 | 1.65 | 3/8″ | 10S | 0.64 |

| 17.15 | 2.31 | 3/8″ | 40S | 0.86 |

| 17.15 | 3.20 | 3/8″ | 80S | 1.12 |

| 21.34 | 2.11 | 1/2″ | 10S | 1.02 |

| 21.34 | 2.77 | 1/2″ | 40S | 1.29 |

| 21.34 | 3.73 | 1/2″ | 80S | 1.65 |

| 26.67 | 2.11 | 3/4″ | 10S | 1.30 |

| 26.67 | 2.87 | 3/4″ | 40S | 1.71 |

| 26.67 | 3.91 | 3/4″ | 80S | 2.23 |

| 33.40 | 2.77 | 1″ | 10S | 2.13 |

| 33.40 | 3.38 | 1″ | 40S | 2.54 |

| 33.40 | 4.55 | 1″ | 80S | 3.29 |

| 48.26 | 2.77 | 1.1/2″ | 10S | 3.16 |

| 48.26 | 3.68 | 1.1/2″ | 40S | 4.11 |

| 48.26 | 5.08 | 1.1/2″ | 80S | 5.49 |

| 60.33 | 2.77 | 2″ | 10S | 3.99 |

| 60.33 | 3.91 | 2″ | 40S | 5.52 |

| 60.33 | 5.54 | 2″ | 80S | 7.60 |

| 88.90 | 3.05 | 3″ | 10S | 6.56 |

| 88.90 | 5.49 | 3″ | 40S | 11.47 |

| 88.90 | 7.62 | 3″ | 80S | 15.51 |

Stainless Steel 904L Tube Size Chart

| Wall Thickness (in) | Available Sizes (in) |

|---|---|

| 0.028″ | 1/16″; 1/8″; 3/16″; 1/4″; 5/16″; 3/8″ |

| 0.035″ | 1/8″; 3/16″; 1/4″; 5/16″; 3/8″; 1/2″; 5/8″; 3/4″; 1″; 1-1/4″; 1-1/2″; 2″ |

| 0.049″ | 1/8″; 3/16″; 1/4″; 5/16″; 3/8″; 1/2″; 5/8″; 3/4″; 1″; 1-1/4″; 1-1/2″; 2″ |

| 0.065″ | 3/16″; 1/4″; 5/16″; 3/8″; 1/2″; 5/8″; 3/4″; 1″; 1-1/4″; 1-1/2″; 2″ |

| 0.083″ | 1/4″; 5/16″; 3/8″; 1/2″; 5/8″; 3/4″; 1″; 1-1/4″; 1-1/2″; 2″; 2-1/2″; 3″ |

| 0.095″ | 1/4″; 3/8″; 1/2″; 5/8″; 3/4″; 1″; 1-1/4″; 1-1/2″; 2″; 2-1/2″; 3″ |

| 0.120″ | 1/2″; 5/8″; 3/4″; 1″; 1-1/4″; 1-1/2″; 2″; 2-1/2″; 3″ |

Pressure Ratings for SS 904L Tubing (PSIG)

| OD (in) | WT 0.028″ | WT 0.035″ | WT 0.049″ | WT 0.065″ | WT 0.083″ | WT 0.095″ | WT 0.109″ | WT 0.120″ |

|---|---|---|---|---|---|---|---|---|

| 1/8″ | 7,900 | 10,100 | N/A | N/A | N/A | N/A | N/A | N/A |

| 1/4″ | 3,700 | 5,800 | 7,900 | 9,500 | N/A | N/A | N/A | N/A |

| 5/16″ | N/A | 3,700 | 5,400 | 7,300 | N/A | N/A | N/A | N/A |

| 3/8″ | N/A | 3,100 | 4,400 | 6,100 | N/A | N/A | N/A | N/A |

| 1/2″ | N/A | 2,300 | 3,200 | 4,400 | N/A | N/A | N/A | N/A |

| 3/4″ | N/A | N/A | 2,100 | 2,900 | 3,900 | 4,500 | N/A | N/A |

| 1″ | N/A | N/A | N/A | 2,200 | 2,900 | 3,400 | 3,900 | 4,300 |

Chemical Composition of Stainless Steel 904L Pipes and Tubes

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.02 max |

| Manganese (Mn) | 2.00 max |

| Phosphorus (P) | 0.045 max |

| Sulfur (S) | 0.035 max |

| Silicon (Si) | 1.00 max |

| Chromium (Cr) | 19.00 – 23.00 |

| Nickel (Ni) | 23.00 – 28.00 |

| Molybdenum (Mo) | 4.00 – 5.00 |

| Copper (Cu) | 1.00 – 2.00 |

| Nitrogen (N) | 0.10 max |

| Iron (Fe) | Balance |

Mechanical Properties of Stainless Steel 904L Pipes and Tubes

| Grade | Tensile Strength (0.2% Offset) min (MPa) | Yield Strength (ksi) min | Elongation (% in 2″) min | Hardness |

|---|---|---|---|---|

| 904L | 490 | 220 | 35 | Rockwell B (90) max Brinell (200) max |

Physical Properties of Stainless Steel 904L Pipes and Tubes

| Grade | Density (kg/m³) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (μm/m°C) | Thermal Conductivity (W/m.K) | Specific Heat 0-100°C (J/kg.K) | Electrical Resistivity (nΩ.m) |

|---|---|---|---|---|---|---|

| 904L | 8000 | 195 | 15.0 (0-100°C) 16.5 (0-300°C) 17.5 (0-500°C) |

12.8 (at 100°C) 16.5 (at 300°C) 19.5 (at 500°C) |

450 | 850 |

Equivalent Grades for Stainless Steel 904L Pipes and Tubes

| STANDARD | WERKSTOFF NR. | UNS | JIS | AFNOR | BS | GOST | EN |

|---|---|---|---|---|---|---|---|

| SS904L | 1.4539 | N08904 | SUS890L | Z2NCDU25-20 | 904S13 | – | X1NiCrMoCu25-20-5 |

💡 Practical Difference in Use

Use 904L when: exceptional corrosion resistance is required in highly aggressive environments, particularly sulfuric acid and chloride-containing media.

→ Example: sulfuric acid concentrators, seawater cooling systems, chemical reactors handling aggressive acids.

Use 904L over 316L/317L when: standard molybdenum grades show inadequate performance in severe corrosive conditions. → Example: phosphoric acid production, pulp digesters, offshore oil and gas systems with high chloride content.

Uses of 904L Stainless Steel Pipes

The uses are defined by its superior corrosion resistance in a wide range of aggressive environments, particularly sulfuric acid and chloride-containing solutions. With high nickel (25%), chromium (21%), and molybdenum (4.5%) content plus copper (1.5%), these pipes handle the most demanding process conditions.

- Transporting Highly Aggressive Chemicals: This is its primary function. It’s used for moving concentrated sulfuric acid, phosphoric acid, chlorinated compounds, and other aggressive media where standard stainless steels fail.

- Severe Service Process Equipment: 904L pipes are essential in reactors, heat exchangers, and columns handling the most corrosive process streams in chemical, petrochemical, and pharmaceutical industries.

- Marine and Offshore Applications: With its exceptional resistance to chloride pitting and crevice corrosion, 904L pipes form critical components in seawater systems, offshore platforms, and marine environments.

When to Choose 904L vs. Standard Austenitic Grades?

This is a critical question. 904L contains high nickel (25%), chromium (21%), molybdenum (4.5%), and copper (1.5%), providing exceptional resistance to sulfuric acid, phosphoric acid, and chloride stress corrosion cracking far beyond 316L/317L capabilities.

Choose 904L when:

- Sulfuric acid concentration ranges from dilute to concentrated at various temperatures

- Chloride levels exceed 10,000 ppm with risk of stress corrosion cracking

- Multiple aggressive chemicals are present simultaneously in the process

Standard grades suffice when:

- Corrosive conditions are well within 316L/317L proven capabilities

- Budget constraints are significant (904L is substantially more expensive)

- Applications involve only mild to moderate corrosive environments

Industries That Use 904L Stainless Steel Pipes

904L stainless steel pipes are essential in industries requiring the highest level of corrosion resistance among standard austenitic stainless steels. Here are the primary industries that rely on this premium alloy:

This industry extensively uses 904L for handling concentrated acids and aggressive chemical combinations.

Uses

Sulfuric acid concentrators, phosphoric acid reactors, pickling equipment, and process piping for mixed acid streams.

Why 904L?

Exceptional resistance to sulfuric acid at all concentrations and temperatures. Copper addition provides superior performance in sulfuric acid environments.

Critical for sour service applications with high H₂S, CO₂, and chloride content.

Uses

Production tubing, flow lines, wellhead components, and process piping in sour gas and oil fields with severe corrosive conditions.

Why 904L?

Superior resistance to chloride stress corrosion cracking and excellent performance in sour service environments with high H₂S partial pressures.

Used in processes involving highly corrosive chemical synthesis and purification.

Uses

Reactor systems, purification columns, and critical process piping for aggressive pharmaceutical intermediates and APIs.

Why 904L?

Excellent resistance to organic and inorganic acids, chlorides, and aggressive cleaning agents used in pharmaceutical manufacturing.

Essential for seawater systems and offshore applications with extreme chloride exposure.

Uses

Seawater cooling pipes, ballast systems, firewater lines, and process piping on offshore platforms and vessels.

Why 904L?

Outstanding resistance to pitting and crevice corrosion in seawater, even in warm tropical waters and stagnant conditions.

Used in the most aggressive sections of pulp digesters and chemical recovery systems.

Uses

Digester piping, bleach plant equipment, black liquor evaporators, and chemical recovery boilers in pulp mills.

Why 904L?

Excellent resistance to acidic sulfite liquors, chlorine compounds, and the complex corrosive mixtures in pulp processing.

Critical for flue gas desulfurization and waste treatment in aggressive environments.

Uses

FGD scrubbers, absorber towers, quench systems, and effluent treatment piping in power plants and industrial facilities.

Why 904L?

Superior resistance to acidic condensates, chlorides, sulfur compounds, and fluctuating pH conditions in pollution control applications.

Essential for aggressive leach solutions and mineral processing chemicals.

Uses

Leach tanks, solvent extraction equipment, acid storage and handling systems, and process piping in hydrometallurgical operations.

Why 904L?

Excellent performance in sulfuric acid leach solutions, chloride-containing process streams, and aggressive chemical environments in mining.

Used in applications with extremely corrosive food products and cleaning regimes.

Uses

Processing equipment for high-acid foods, vinegar concentration, pickle production, and systems using aggressive acid-based sanitizers.

Why 904L?

Superior resistance to organic acids (acetic, citric, lactic) and chlorinated cleaning compounds that rapidly corrode standard grades.

Request a Quote

Looking for premium 904L Pipes & Tubes? Contact us today to get the best prices.

Contact Us