High Quality Stainless Steel 304/304L Pipes & Tubes

Seamless • Welded • Durable & Precise

Get a QuoteWhat is 304 & 304L Stainless Steel?

304 stainless steel is the standard “workhorse” grade. Its excellent corrosion resistance and good mechanical properties make it suitable for a vast range of applications. 304L is a low-carbon variation of the standard 304 stainless steel. Its unique properties make it ideal for various industrial applications where corrosion resistance and weldability are critical.

304 Stainless Steel

Chromium (Cr)

Nickel (Ni)

Carbon (C) Max

Manganese (Mn) Max

Silicon (Si) Max

Phosphorus (P) Max

Sulfur (S) Max

Iron (Fe)

304L Stainless Steel

Chromium (Cr)

Nickel (Ni)

Carbon (C) Max

Manganese (Mn) Max

Silicon (Si) Max

Phosphorus (P) Max

Sulfur (S) Max

Iron (Fe)

Types of Stainless Steel 304 & 304L Pipes & Tubes

As premier manufacturers in the industry, we specialize in producing both stainless steel 304/304L seamless pipes & tubes and stainless steel 304/304L welded pipes & tubes, offering comprehensive solutions for diverse industrial requirements.

Manufactured from solid billets through an extrusion process, these pipes deliver superior strength and exceptional pressure resistance. Seamless construction eliminates weld seams, making them the preferred choice for critical applications involving high-pressure systems and aggressive corrosive environments where welding integrity is paramount.

These pipes provide an economical alternative with availability across a broader spectrum of sizes and dimensions. Welded pipes excel in structural applications, low-pressure systems, and general corrosive service conditions where reliable welded joints are essential. Their cost-effectiveness makes them ideal for projects with budget constraints without compromising performance.

Specification of Stainless Steel 304/304L Seamless & Welded Pipes And Tubes

| Specification | Details |

|---|---|

| Stainless Steel Pipe Specification | ASTM A312, A358 / ASME SA312, SA358 |

| SS Tube Specification | ASTM A213, A269, A249, A511, A554 / ASME SA213, SA269, SA249, SA511, SA554 |

| Pipe Size | 1/8” NB to 24” NB, 1/4” OD to 24” OD sizes |

| Tube Size | 1/2″ OD to 8″ OD |

| Thickness Range | 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Type | Seamless / ERW / Welded / Fabricated Pipes |

| Form | Round, Square, Rectangular, Oval, Hydraulic Etc |

| Length | Single Random, Double Random & Required Length |

| End | Plain End, Beveled End, Threaded |

| End Protection | Plastic Caps |

| Outside Finish | 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Inspection, Test Reports | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be manufactured on request |

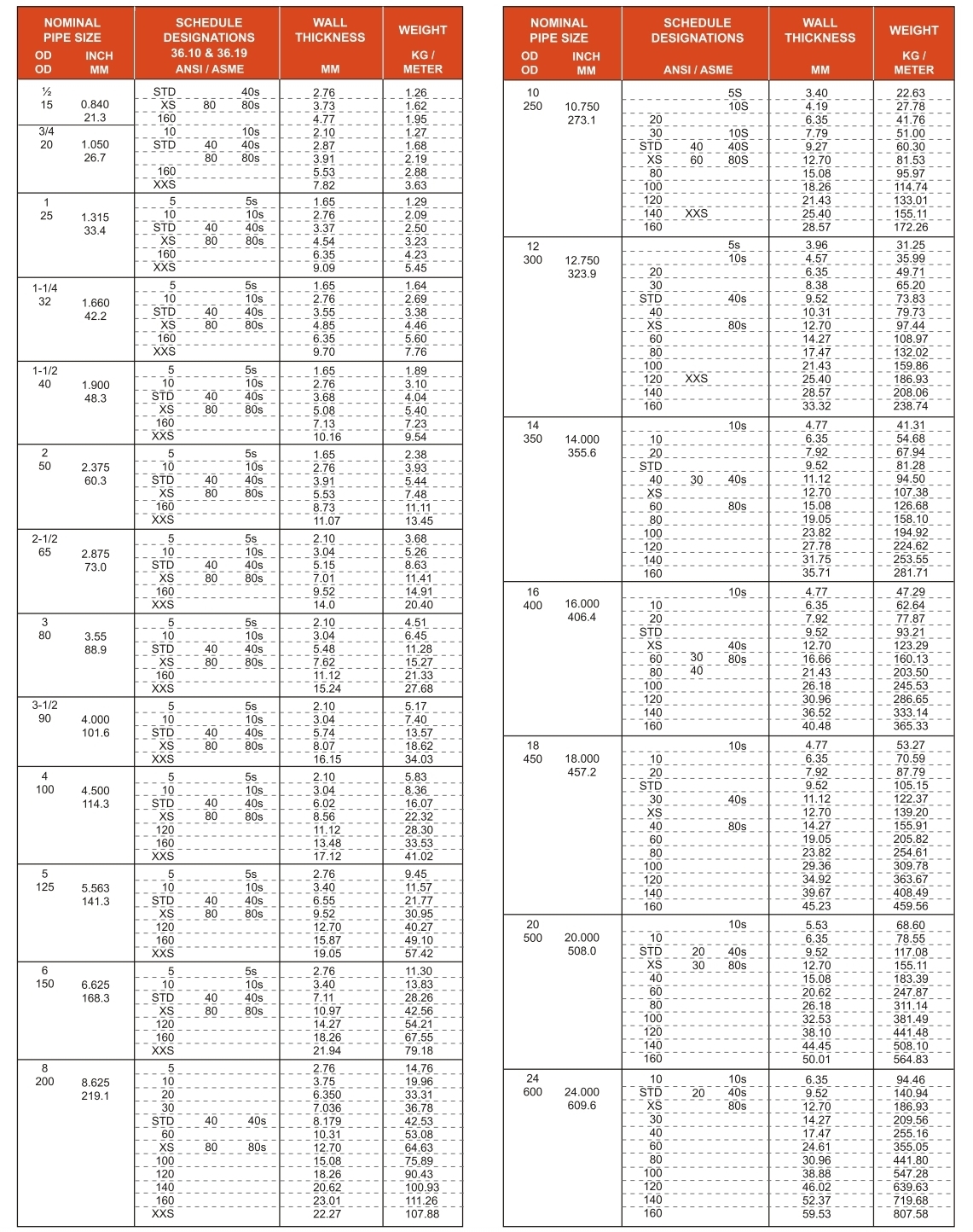

STAINLESS STEEL PIPE & TUBES SCHEDULE DIMENSIONS WALL THICKNESS, WT./MTR. (KG)

Click to expand ▼

Stainless Steel 304/304L Pipe Dimensions & Weight Chart

| OD (mm) | WT (mm) | NPS (dn) | Schedule | Weight (kg/m) |

|---|---|---|---|---|

| 13.72 | 1.65 | 1/4″ | 10S | 0.50 |

| 13.72 | 2.24 | 1/4″ | 40S | 0.64 |

| 13.72 | 3.02 | 1/4″ | 80S | 0.81 |

| 17.15 | 1.65 | 3/8″ | 10S | 0.64 |

| 17.15 | 2.31 | 3/8″ | 40S | 0.86 |

| 17.15 | 3.20 | 3/8″ | 80S | 1.12 |

| 21.34 | 2.11 | 1/2″ | 10S | 1.02 |

| 21.34 | 2.77 | 1/2″ | 40S | 1.29 |

| 21.34 | 3.73 | 1/2″ | 80S | 1.65 |

| 26.67 | 2.11 | 3/4″ | 10S | 1.30 |

| 26.67 | 2.87 | 3/4″ | 40S | 1.71 |

| 26.67 | 3.91 | 3/4″ | 80S | 2.23 |

| 33.40 | 2.77 | 1″ | 10S | 2.13 |

| 33.40 | 3.38 | 1″ | 40S | 2.54 |

| 33.40 | 4.55 | 1″ | 80S | 3.29 |

| 48.26 | 2.77 | 1.1/2″ | 10S | 3.16 |

| 48.26 | 3.68 | 1.1/2″ | 40S | 4.11 |

| 48.26 | 5.08 | 1.1/2″ | 80S | 5.49 |

| 60.33 | 2.77 | 2″ | 10S | 3.99 |

| 60.33 | 3.91 | 2″ | 40S | 5.52 |

| 60.33 | 5.54 | 2″ | 80S | 7.60 |

| 88.90 | 3.05 | 3″ | 10S | 6.56 |

| 88.90 | 5.49 | 3″ | 40S | 11.47 |

| 88.90 | 7.62 | 3″ | 80S | 15.51 |

Stainless Steel 304/304L Tube Size Chart

| Wall Thickness (in) | Available Sizes (in) |

|---|---|

| 0.028″ | 1/16″; 1/8″; 3/16″; 1/4″; 5/16″; 3/8″ |

| 0.035″ | 1/8″; 3/16″; 1/4″; 5/16″; 3/8″; 1/2″; 5/8″; 3/4″; 1″; 1-1/4″; 1-1/2″; 2″ |

| 0.049″ | 1/8″; 3/16″; 1/4″; 5/16″; 3/8″; 1/2″; 5/8″; 3/4″; 1″; 1-1/4″; 1-1/2″; 2″ |

| 0.065″ | 3/16″; 1/4″; 5/16″; 3/8″; 1/2″; 5/8″; 3/4″; 1″; 1-1/4″; 1-1/2″; 2″ |

| 0.083″ | 1/4″; 5/16″; 3/8″; 1/2″; 5/8″; 3/4″; 1″; 1-1/4″; 1-1/2″; 2″; 2-1/2″; 3″ |

| 0.095″ | 1/4″; 3/8″; 1/2″; 5/8″; 3/4″; 1″; 1-1/4″; 1-1/2″; 2″; 2-1/2″; 3″ |

| 0.120″ | 1/2″; 5/8″; 3/4″; 1″; 1-1/4″; 1-1/2″; 2″; 2-1/2″; 3″ |

Pressure Ratings for SS 304/304L Tubing (PSIG)

| OD (in) | WT 0.028″ | WT 0.035″ | WT 0.049″ | WT 0.065″ | WT 0.083″ | WT 0.095″ | WT 0.109″ | WT 0.120″ |

|---|---|---|---|---|---|---|---|---|

| 1/8″ | 7,900 | 10,100 | N/A | N/A | N/A | N/A | N/A | N/A |

| 1/4″ | 3,700 | 5,800 | 7,900 | 9,500 | N/A | N/A | N/A | N/A |

| 5/16″ | N/A | 3,700 | 5,400 | 7,300 | N/A | N/A | N/A | N/A |

| 3/8″ | N/A | 3,100 | 4,400 | 6,100 | N/A | N/A | N/A | N/A |

| 1/2″ | N/A | 2,300 | 3,200 | 4,400 | N/A | N/A | N/A | N/A |

| 3/4″ | N/A | N/A | 2,100 | 2,900 | 3,900 | 4,500 | N/A | N/A |

| 1″ | N/A | N/A | N/A | 2,200 | 2,900 | 3,400 | 3,900 | 4,300 |

Chemical Composition of Stainless Steel 304/304L Pipes and Tubes

| Element | 304 Stainless Steel (%) | 304L Stainless Steel (%) |

|---|---|---|

| Carbon (C) | 0.08 max | 0.030 max |

| Manganese (Mn) | 2.00 max | 2.00 max |

| Phosphorus (P) | 0.045 max | 0.045 max |

| Sulfur (S) | 0.030 max | 0.030 max |

| Silicon (Si) | 0.75 max | 0.75 max |

| Chromium (Cr) | 18.00 – 20.00 | 18.00 – 20.00 |

| Nickel (Ni) | 8.00 – 10.50 | 8.00 – 12.00 |

| Nitrogen (N) | 0.10 max | 0.10 max |

| Iron (Fe) | Balance | Balance |

Mechanical Properties of Stainless Steel 304/304L Pipes and Tubes

| Grade | Tensile Strength (0.2% Offset) min (MPa) | Yield Strength (ksi) min | Elongation (% in 2″) min | Hardness |

|---|---|---|---|---|

| 304L | 485 | 170 | 40 | Rockwell B (92) max Brinell (201) max |

Physical Properties of Stainless Steel 304/304L Pipes and Tubes

| Grade | Density (kg/m³) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (μm/m°C) | Thermal Conductivity (W/m.K) | Specific Heat 0-100°C (J/kg.K) | Electrical Resistivity (nΩ.m) |

|---|---|---|---|---|---|---|

| 304L | 8000 | 193 | 17.2 (0-100°C) 17.8 (0-315°C) 18.4 (0-538°C) |

16.2 (at 100°C) 21.5 (at 500°C) |

500 | 720 |

Equivalent Grades for Stainless Steel 304/304L Pipes and Tubes

| STANDARD | WERKSTOFF NR. | UNS | JIS | AFNOR | BS | GOST | EN |

|---|---|---|---|---|---|---|---|

| SS304L | 1.4306 / 1.4307 | S30403 | SUS304L | Z3CN18-10 | 304S11 | 03X18H11 | X2CrNi18-9 / X2CrNi19-11 |

💡 Practical Difference in Use

Use 304 when: strength and hardness are more important, and welding is minimal.

→ Example: structural parts, decorative tubes, mechanical components.

Use 304L when: extensive welding is involved or in corrosive or chemical environments. → Example: chemical process piping, welded tanks, and equipment exposed to acids or moisture.

Uses of 304/304L Stainless Steel Pipes

The uses are defined by its excellent corrosion resistance, good formability, and hygiene. Pipes are used to convey, transfer, and transport various substances.

- Transporting Corrosive Liquids & Gases: This is its primary function. It’s used for moving everything from mild chemicals and solvents to potable water and various process streams.

- Structural and Mechanical Components: While not as common as tubing for structural frames, pipes can be used for handrails, supports, and safety barriers in corrosive environments where their corrosion resistance is a benefit.

- High-Purity and Sanitary Systems: With the right polishing (e.g., Electropolished) and connections, 304L pipes form the backbone of systems where purity and cleanability are paramount.

When to Choose 304L vs. 316L?

This is a critical question. 304L is the default, general-purpose choice. 316L contains Molybdenum (2-3%), which gives it significantly better resistance to pitting and crevice corrosion, especially from chlorides.

Choose 304L when:

- The environment involves mild corrosives like fresh water, most foods, alcohols, and many organic chemicals.

- Cost is a significant factor (304L is less expensive than 316L).

- The primary threat is uniform corrosion, not pitting.

Upgrade to 316L when:

- The environment contains significant chlorides (e.g., saltwater, coastal air, heavy road salts, strong bleach solutions).

- The application is in a marine environment or a chemical plant with more aggressive acids.

Industries That Use 304L Stainless Steel Pipes

Virtually every industry that requires corrosion-resistant piping uses 304L. Here are the most prominent ones:

This is a massive consumer of 304L pipes. The material is non-reactive, doesn’t impart taste or odor, and is easy to clean and sterilize.

Uses

Transporting ingredients (water, milk, beer, juice, oils), process lines, brewing systems, and CIP (Clean-in-Place) systems.

Why 304L?

Resists corrosion from organic acids and cleaning agents (like chlorides in sanitizers). Its weld integrity prevents crevices where bacteria could grow.

This industry demands extreme hygiene and purity. 304L is often the baseline material.

Uses

Process piping for purified water, water-for-injection (WFI), and active pharmaceutical ingredients (APIs). Also used in vent lines and clean utility systems.

Why 304L?

Prevents contamination, withstands repeated sterilization with high-purity steam, and its smooth surface is easy to keep sterile.

For handling mild to moderately corrosive chemicals at various temperatures and pressures.

Uses

Transfer lines for organic chemicals, solvents, acids (like nitric acid), and intermediates. Often used in heat exchangers and coolers.

Why 304L?

Excellent general corrosion resistance. The “L” grade is crucial here because welded joints are common and must resist attack from process chemicals.

From the plant to your tap, 304L is commonly used.

Uses

Potable water distribution, plumbing systems, water filtration lines, and components in desalination plants.

Why 304L?

Excellent resistance to a wide range of water types, including those with chlorides used for disinfection. It doesn’t rust, ensuring water quality.

While more corrosive offshore environments require higher grades (like 316L), 304L is used in many onshore and “sweet” service applications.

Uses

Gathering lines, utility lines (for water, air), and instrumentation tubing in less aggressive environments.

Why 304L?

A cost-effective solution where the corrosive threat (e.g., H₂S and chlorides) is low enough.

Its aesthetic appeal and durability make it a popular choice.

Uses

Handrails, balustrades, decorative trims, and structural members in humid or coastal environments.

Why 304L?

Resists atmospheric corrosion and rusting, maintaining its appearance over time. Welding during installation doesn’t compromise its corrosion resistance.

The paper-making process involves many corrosive chemicals.

Uses

Piping for bleaching chemicals, stock preparation, and water circulation systems.

Why 304L?

Withstands the corrosive nature of chlorides and other chemicals used in the pulping process.

Used in specific subsystems rather than for primary structures.

Uses

Hydraulic lines, exhaust systems, fuel lines (in certain sections), and coolant pipes.

Why 304L?

Provides a good balance of strength, formability, and resistance to heat and corrosion from fuels and exhaust gases.

Request a Quote

Looking for premium Stainless Steel 304 | 304L Pipes & Tubes? Contact us today to get the best prices.

Contact Us