Premium Stainless Steel 304/304L/304H Buttweld Pipe Fittings by Ratnadeep Steel & Engg. Co.

Ratnadeep Steel & Engg. Co. is a leading manufacturer, exporter, and supplier of premium-quality Stainless Steel 304/304L/304H Buttweld Pipe Fittings. These fittings are engineered from high-grade austenitic stainless steel and manufactured using advanced production techniques to ensure superior strength, dimensional accuracy, and long-term service reliability. Our products are widely used in industries that demand excellent corrosion resistance, heat resistance, and leak-proof flow performance.

Stainless Steel 304, 304L, and 304H are the most widely used grades of the austenitic stainless-steel family. Their buttweld fittings are designed with beveled ends, which enable full penetration welding, producing a strong and permanent joint. These fittings allow a smooth, continuous metal structure inside the piping system, minimizing turbulence, reducing pressure loss, and preventing corrosion and erosion.

- ASTM A403 WP304 / 304L Stainless Steel Pipe Elbow

- SS 304 / 304L / 304H Elbow

- 304 SS 90° Elbow, 304L SS 45° Elbow

- UNS S30400 / S30403 / S30409 LR & SR Elbows

- DIN 1.4301 / 1.4306 Short & Long Radius Elbows

- ASTM A403 WP304 Stainless Steel Equal Tee

- ASME B16.9 Stainless Steel 304H Pipe Tee

- DIN 1.4301 Butt Weld Tee

- ASME SA403 304L Reducing Tee

- DIN 1.4307 Unequal Tee

- UNS S30400 / S30403 / S30409 Tees

- A403 WP304L Stainless Steel Straight Tee

- ASME B16.9 Stainless Steel 304 Eccentric Reducer

- ASTM A403 WP304L Stainless Steel Eccentric Reducer

- ASTM A403 WP304H SS Eccentric Reducer

- UNS S30400 / S30403 Stainless Steel Eccentric Reducers

- DIN 1.4301 Stainless Steel Eccentric Reducer

- A403 WP304 / 304L Stainless Steel Concentric Reducer

- SS 304 / 304L / 304H Concentric Reducer

- ANSI B16.9 SS 304 Concentric Reducer

- ASME SA403 WP304L SS Concentric Reducer

- Stainless Steel 304H Concentric Reducer

- UNS S30400 / S30403 Concentric Reducers

- DIN 1.4301 / 1.4307 Stainless Steel Concentric Reducer

- ASTM A403 WP304 Stainless Steel Long Stub End

- ASME B16.9 Stainless Steel 304L Long Stub Ends

- UNS S30400 / S30403 / S30409 Long Stub End

- SS 304H Long Stub End

- SS 304 / 304L Lap Joint Stub End

- DIN 1.4301 / 1.4307 Stainless Steel Long Stub End

- ASTM A403 SS 304 Short Stub End Supplier

- ASME B16.9 Stainless Steel A403 WP304H Short Stub Ends

- ASME SA403 Stainless Steel 304H Short Stub End

- SS UNS S30400 Short Stub Ends

- DIN 1.4307 Stainless Steel Short Stub End

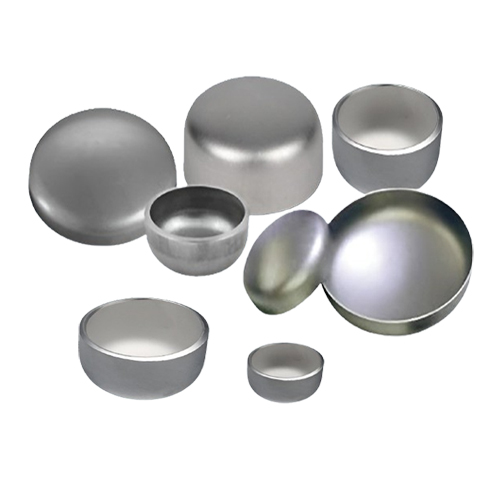

- ASTM A403 / SA403 Stainless Steel WP304 Pipe Cap Supplier

- ASME B16.9 SS 304L End Pipe Cap

- SS UNS S30400 Pipe End Cap

- UNS S30403 Buttweld Cap

- DIN 1.4301 Stainless Steel Cap

- A403 WP304H Buttweld Pipe Cap

- UNS S30409 Stainless Steel End Cap

- ASTM A403 Stainless Steel 304 Equal Cross

- ASME B16.9 SS 304L Buttweld Cross

- ASTM A403 WP304H Stainless Steel Cross

- SS UNS S30400 / S30403 Unequal Cross

- SS UNS S30409 Stainless Steel Cross

- DIN 1.4301 Stainless Steel Reducing Cross

- ASME SA403 Stainless Steel 304 Pipe Bend Exporter

- B16.9 Stainless Steel 304L Piggable Bend

- UNS S30400 / S30403 / S30409 Stainless Steel U Bend

- SS DIN 1.4307 Long Radius Bend

- ASTM A403 Stainless Steel 304H Buttweld Bend

CHEMICAL COMPOSITION OF SS 304/304L/304H SEAMLESS AND WELDED PIPE FITTINGS

| C | Mn | Si | P | S | Cr | Ni | N | |

|---|---|---|---|---|---|---|---|---|

| 304 | 0.07max | 2.0max | 0.75max | 0.045max | 0.03max | min: 18.0 max: 20.0 |

min: 8.0 max: 10.5 |

— |

| 304L | 0.03max | 2.0max | 0.75max | 0.045max | 0.03max | min: 18.0 max: 20.0 |

min: 8.0 max: 12.0 |

0.10 max |

| 304H | min: 0.04 max: 0.10 |

2.0 max | 0.75 max | 0.045 max | 0.03 max | min: 18.0 max: 20.0 |

min: 8.0 max: 10.5 |

0.10 max |

MECHANICAL PROPERTIES OF ASME SA403 SS WP304 / 304L/ 304H BUTTWELD PIPE FITTINGS

| Grade | Tensile Strength ksi (min) | Yield Strength 0.2% ksi (min) | Elongation % | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

|---|---|---|---|---|---|

| 304 | 75 | 30 | 40 | 201 | 92 |

| 304L | 70 | 25 | 40 | 201 | 92 |

| 304H | 75 | 30 | 40 | 201 | 92 |

SPECIFICATION OF SS 304/304L/304H BUTTWELL FITTINGS

| Specifications | ASTM A403 / ASME SA403 |

|---|---|

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | Seamless Butt Weld Fittings: ½” to 10″ | Welded Butt Weld Fittings: ½” to 48″ |

| Schedule | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Type | Seamless / ERW / Welded / Fabricated |

| Thickness | 20 Swg., 18 Swg., 16 Swg., 14 Swg., 12 Swg., 10 Swg., & Sch. 10, Sch. 40, Sch. 80 etc. |

304/304L/304H STAINLESS STEEL ASTM A403 BUTTWELD FITTINGS EQUIVALENT GRADES

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST |

|---|---|---|---|---|---|---|---|

| SS 304 | S30400 | 1.4301 | Z7CN18-09 | X5CrNi18-10 | SUS 304 | 304S31 | 08X18H10 |

| SS 304L | S30403 | 1.4306/1.4307 | Z3CN18-10 | X2CrNi18-9/X2CrNi19-11 | SUS 304L | 304S11 | 03X18H11 |

| SS 304H | S30409 | 1.4301 | – | – | – | – | – |

PHYSICAL PROPERTIES OF ASTM A403 STAINLESS STEEL 304/304L/304H PIPE FITTINGS

SS 304/304L

| Density lbm/in³ | Thermal Conductivity (BTU/h ft. °F) | Electrical Resistivity (in x 10⁶) | Modulus of Elasticity (psi x 10⁶) | Coefficient of Thermal Expansion (in/in)/ °F x 10⁶ | Specific Heat (BTU/lb/ °F) | Melting Range (°F) |

|---|---|---|---|---|---|---|

| at 68°F: 0.285 | 9.4 at 212°F 12.4 at 932°F |

28.3 at 68°F 39.4 at 752°F 49.6 at 1652°F |

28 | 9.4 at 32 – 212°F 10.2 at 32 – 1000°F 10.4 at 32 – 1500°F |

0.1200 at 68°F to 212°F | 2500 to 2590 |

SS 304H

| Density lbm/in³ | Coefficient of Thermal Expansion (min/in)-°F | Thermal Conductivity BTU/hr-ft.-°F | Specific Heat BTU/lbm -°F | Modules of Elasticity (annealed)-²-psi |

|---|---|---|---|---|

| at 68 °F: 0.285 | at 68 – 212°F: 9.2 at 68 – 1600°F: 11.0 |

at 212°F: 9.4 at 932°F: 12.4 |

at 32 – 212°F: 0.12 | in tension (E): 29 x 10⁶ |

💡 Practical Difference in Use

Use Stainless Steel 304/304L/304H Buttweld Pipe Fittings when: excellent corrosion resistance, smooth flow characteristics, high weldability, and reliable leak-proof connections are required in chemical, food, petrochemical, and structural applications. → Example: fluid processing lines, heat exchanger pipelines, high-pressure systems, water treatment facilities, and architectural piping.

Applications of SS 304/304L/304H Buttweld Pipe Fittings

Stainless Steel 304/304L/304H Buttweld Pipe Fittings deliver superior corrosion resistance, high strength, and smooth flow transition, making them ideal for critical industrial piping systems.

- Chemical & Petrochemical: Process piping, heat exchangers, reactors, and high-temperature fluid lines.

- Food & Beverage: Hygienic and corrosion-resistant flow lines for liquid, steam, and cleaning systems.

- Pharmaceuticals: Purified water systems, clean-in-place (CIP) lines, and sterile process equipment.

When to Choose SS 304/304L/304H?

These grades are chosen for applications requiring high corrosion resistance, excellent weldability, smooth internal flow, and long-term durability under moderate and high temperatures.

Choose SS 304/304L/304H when:

- Corrosion resistance in various media is critical

- Strong, leak-proof welded joints are required

- Smooth internal surface is needed to reduce erosion and turbulence

- High temperature strength is required (304H)

- Used in heat exchangers, reactors, pipelines, and processing plants

Industries That Use SS 304/304L/304H Buttweld Pipe Fittings

These fittings are used across industries that demand corrosion resistance, strong weldable connections, hygienic surfaces, and smooth flow transitions.

Ideal for pipelines carrying corrosive fluids and chemicals.

Uses

Heat exchanger lines, reactor piping, and process fluid transport.

Why SS 304/304L/304H?

Excellent corrosion resistance, weldability, and durability under varying temperatures.

Used in hygienic and sanitary applications with strict cleanliness requirements.

Uses

Steam lines, dairy pipelines, beverage transport, and cleaning systems.

Why SS 304/304L/304H?

Non-reactive, corrosion-resistant, smooth internal surface prevents contamination.

Critical for sterile and contamination-free processing lines.

Uses

WFI systems, CIP/SIP piping, and clean process equipment.

Why SS 304/304L/304H?

Easy to clean, excellent corrosion resistance, and precise weldability.

Usage guide for SS 304/304L/304H Buttweld Pipe Fittings

Smooth and controlled directional change in pipelines.

Choose Elbow when

- 45°, 90°, or 180° direction change is required

- Minimal pressure drop is important

- Used in chemical, food, and high-pressure lines

- Clean and corrosion-resistant flow path is needed

Creates branch connections in pipelines.

Choose Tee when

- Equal or unequal branching is required

- High flow distribution efficiency is needed

- Used in multi-line distribution systems

- Leak-proof welded joints are essential

Maintains top or bottom alignment in pipelines.

Choose Eccentric Reducer when

- Avoiding air pockets is critical

- Pump suction lines are involved

- Horizontal piping systems are used

- Flow disturbance must be minimized

Uniform transition between different pipe diameters.

Choose Concentric Reducer when

- Centered pipe alignment is required

- Vertical piping systems are used

- Smooth flow reduction is needed

- Used in pump discharge lines

Used with lap joint flanges for easy dismantling.

Choose Long Stub End when

- Frequent dismantling is required

- Cost-effective flange solutions are needed

- Corrosion-prone environments exist

- Low-pressure or hygienic systems are used

Compact and economical lap joint connection.

Choose Short Stub End when

- Space constraints exist

- Economical flange connections are needed

- Used in food and pharma lines

- Clean and corrosion-resistant materials are required

Seals the end of a pipeline securely.

Choose Pipe Cap when

- Pipe ends must be closed

- Used for pressure testing or isolation

- Leak-proof sealing is essential

- Corrosion resistance is required

Four-way branch connection for complex systems.

Choose Cross when

- Flow must be split in multiple directions

- Used in firefighting and chemical systems

- High-strength welded joints are required

- Long-term corrosion resistance is needed

Large-radius directional change for smooth flow.

Choose Pipe Bend when

- Gradual direction change is required

- Used in refineries and long pipelines

- Turbulence and pressure loss must be low

- Durable, corrosion-resistant flow paths are needed

Our Buttweld Pipe Fittings are manufactured using advanced processes and undergo extensive quality checks to ensure flawless weldability, durability, and long service life. Each fitting is thoroughly inspected using key NDT techniques such as radiographic testing (RT), ultrasonic testing (UT), hydrostatic testing, and visual/dimensional examination. We also perform detailed chemical composition analysis and mechanical property testing to ensure material compliance with strict industry standards.

Throughout the forming and welding stages, every buttweld fitting is monitored closely to eliminate defects such as misalignment, surface irregularities, and wall-thickness variations. This ensures perfect joint integrity and high-performance reliability in pipelines carrying high temperatures, pressures, and corrosive media. All our buttweld fittings fully comply with ASME, ASTM, MSS-SP, and related global specifications, making them a preferred choice for critical piping systems worldwide.

Request a Quote

Looking for high-quality Stainless Steel Grade 304/304L/304H Buttweld Pipe Fittings? Get in touch with us today.

Contact Us