High Quality Inconel Buttweld Pipe Fittings

600/601/625/718 • Strength • Sealing • Durability

Get a QuotePremium Inconel 600/601/625/718 Buttweld Pipe Fittings by Ratnadeep Steel & Engg. Co.

Ratnadeep Steel & Engg. Co. is a trusted manufacturer, exporter, & supplier of Inconel 600/601/625/718 Buttweld Pipe Fittings. Manufactured using high-performance nickel-chromium-based superalloys, these fittings deliver outstanding strength, excellent oxidation resistance, and exceptional durability under extreme temperatures and aggressive chemical environments.

Inconel alloys 600, 601, 625, and 718 are specifically engineered to provide superior resistance to oxidation, carburization, chloride-induced stress corrosion cracking, and high-temperature creep. These grades retain excellent mechanical properties across a wide temperature range, making them ideal for critical service conditions in aerospace, chemical processing, nuclear power, marine engineering, and oil & gas industries. Our Inconel buttweld fittings are precision-beveled to allow full-penetration welding, ensuring high-integrity, leak-proof joints.

Designed for smooth internal flow, reduced pressure drop, and long-term reliability, our Inconel buttweld pipe fittings are widely used in heat exchangers, pressure vessels, furnace components, exhaust systems, and high-temperature piping applications. Choose Ratnadeep Steel & Engg. Co. for premium-quality Inconel 600/601/625/718 buttweld fittings that conform to international standards and meet the most demanding industrial specifications.

- Inconel 600 90 Deg Elbow

- Alloy 601 45 Deg Elbow

- Inconel 625 180 Deg Elbow

- UNS N06600 LR Elbow

- DIN 2.4856 SR Elbow

- ANSI B16.9 Alloy 718 90 Degree Short Radius Elbow

- DIN 2.4668 45 Deg Long Radius Elbow

- ASME B16.9 Alloy 600 Equal Tee

- Inconel 601 Pipe Tee

- Inconel 625 Butt weld Tee

- ASME SB366 Inconel 718 Reducing Tee manufacturer

- DIN 2.4816 Unequal Tee

- Alloy UNS N06625 Straight Tee

- ASTM B366 Inconel 600 Eccentric Reducer Supplier

- B16.9 Inconel 601 Eccentric Reducer

- Alloy 625 Eccentric Reducers

- SB366 Inconel 718 Eccentric Reducer

- ANSI B16.9 Inconel Alloy 600 Concentric Reducer Supplier

- ASME SB366 Inconel 601 Concentric Reducer

- Inconel 625 Concentric Reducers

- ASTM B366 Alloy 718 Concentric Reducer

- ASME B16.9 Inconel Alloy 600 Long Stub End Supplier

- ASTM B366 Inconel 601 Long Stub Ends

- Alloy 625 Lap Joint Stub End

- Inconel 718 Long Stub End

- ASTM B366 Inconel 600 Short Stub End Supplier

- ASME B16.9 Inconel Alloy 601 Short Stub Ends

- Alloy UNS N06625 Short Stub Ends

- DIN 2.4668 Short Stub End

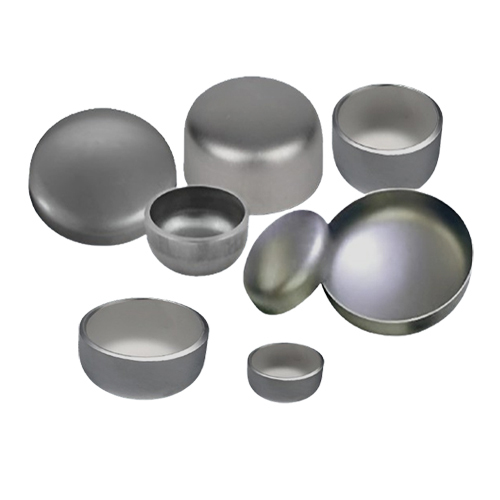

- ASTM B366 / SB366 Inconel 600 Pipe Cap Supplier

- ASME B16.9 Inconel Alloy 601 End Pipe Cap

- Inconel Alloy 625 Pipe End Cap

- Inconel 718 Buttweld Cap

- Inconel End Cap

- ASTM B366 / SB366 Inconel 600 Equal Cross

- ASME B16.9 Inconel Alloy 601 Buttweld Cross

- Alloy UNS N06600 / N06601 Unequal Cross

- Inconel UNS N06625 | N07718 Reducing Cross

- ASME SB 366 Inconel Alloy 600 Pipe Bend Exporter

- B16.9 Inconel 601 Piggable Bend

- Inconel 625 U Bend

- Inconel 718 Long Radius Bend

- DIN 2.4816 Buttweld Bend

CHEMICAL COMPOSITION OF INCONEL ALLOY SEAMLESS AND WELDED PIPE FITTINGS

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

|---|---|---|---|---|---|---|---|---|

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015 max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

| Inconel 601 | 0.10 max | 1.0 max | 0.5 max | 0.015 max | 1.0 max | Balance | 58.0 – 63.0 | 21.0 – 25.0 |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | – | 5.0 max | 58.0 min | 20.0 – 23.0 |

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015 max | 0.30 max | – | 50.00 – 55.00 | 17.00 – 21.00 |

MECHANICAL PROPERTIES OF ASME SB366 INCONEL BUTTWELD PIPE FITTINGS

| Grade | Tensile Strength | Yield Strength (0.2% Offset) | Elongation |

|---|---|---|---|

| Inconel 600 | Psi – 95,000, MPa – 655 | Psi – 45,000, MPa – 310 | 40% |

| Inconel 601 | Psi – 80,000, MPa – 550 | Psi – 30,000, MPa – 205 | 30% |

| Inconel 625 | Psi – 135,000, MPa – 930 | Psi – 75,000, MPa – 517 | 42.5% |

| Inconel 718 | Psi – 135,000, MPa – 930 | Psi – 75,000, MPa – 482 | 45% |

SPECIFICATION OF INCONEL ALLOY BUTTWELL FITTINGS

| Specifications | ASTM B366 / ASME SB366 |

|---|---|

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | Seamless Butt Weld Fittings: ½” to 10″ | Welded Butt Weld Fittings: ½” to 48″ |

| Schedule | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Type | Seamless / ERW / Welded / Fabricated |

| Thickness | 20 Swg., 18 Swg., 16 Swg., 14 Swg., 12 Swg., 10 Swg., & Sch. 10, Sch. 40, Sch. 80 etc. |

600/601/625/718 INCONEL ASTM B366 BUTTWELD FITTINGS EQUIVALENT GRADES

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | MHXMu 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

| Inconel 601 | 2.4851 | N06601 | NCF 601 | NA 49 | XH60BT | NC23FeA | NiCr23Fe |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | XH75MBTiO | NC22DNB4M | NiCr22Mo9Nb |

| Inconel 718 | 2.4668 | N07718 | – | – | – | – | – |

PHYSICAL PROPERTIES OF INCONEL ALLOY SEAMLESS AND WELDED PIPE FITTINGS

| Grade | Density | Melting Point |

|---|---|---|

| Inconel 600 | 8.47 g/cm³ | 1413 °C (2580 °F) |

| Inconel 601 | 8.1 g/cm³ | 1411 °C (2571 °F) |

| Inconel 625 | 8.4 g/cm³ | 1350 °C (2460 °F) |

| Inconel 718 | 8.2 g/cm³ | 1350 °C (2460 °F) |

💡 Practical Difference in Use

Use Inconel 600/601/625/718 Buttweld Pipe Fittings when: exceptional strength, high-temperature stability, and superior resistance to oxidation, carburization, and aggressive chemical attack are required. These nickel-based superalloys are specifically engineered to maintain mechanical integrity under extreme heat, pressure, and corrosive conditions, including chloride-induced stress corrosion cracking. → Example: aerospace and turbine systems, chemical processing plants, nuclear power facilities, heat exchangers, furnace components, exhaust systems, and high-temperature pressure piping.

Applications of Inconel 600/601/625/718 Buttweld Pipe Fittings

Inconel Buttweld Pipe Fittings are designed to provide outstanding resistance to high temperatures, oxidation, and severe chemical environments while maintaining excellent mechanical strength and weldability.

- Chemical & Petrochemical: High-temperature reactors, chemical processing lines, and aggressive fluid transfer systems.

- Aerospace & Power Generation: Gas turbines, exhaust systems, heat exchangers, and high-pressure piping.

- Nuclear & Marine Applications: Nuclear reactor components, seawater-cooled systems, and corrosion-resistant piping.

When to Choose Inconel 600/601/625/718?

These Inconel grades are ideal for applications that demand exceptional performance under extreme temperatures, high pressure, and chemically aggressive environments where conventional stainless steels fail.

Choose Inconel 600/601/625/718 when:

- Operating temperatures are extremely high and continuous strength retention is required

- Equipment is exposed to oxidation, carburization, or aggressive chemical attack

- High-pressure piping requires superior fatigue and creep resistance

- Welded joints must perform reliably under thermal cycling

- Used in aerospace, nuclear, chemical processing, or high-temperature industrial systems

Industries That Use Inconel 600/601/625/718 Buttweld Pipe Fittings

Inconel fittings are widely used in industries where extreme temperature resistance, superior strength, and long-term operational reliability are critical.

Designed for severe chemical environments combined with elevated operating temperatures.

Uses

High-temperature reactors, chemical transfer piping, and corrosion-resistant process systems.

Why Inconel?

Provides outstanding resistance to oxidation, chemical attack, and stress corrosion cracking at high temperatures.

Preferred for high-temperature and high-stress aerospace and energy applications.

Uses

Gas turbines, exhaust systems, heat exchangers, and pressure piping.

Why Inconel?

Maintains exceptional strength and fatigue resistance under extreme thermal and mechanical stress.

Used in mission-critical systems requiring unmatched reliability.

Uses

Nuclear reactor components, seawater handling systems, and corrosion-resistant piping.

Why Inconel?

Superior resistance to radiation, chloride environments, and high-temperature corrosion ensures long service life.

Usage Guide for Inconel 600/601/625/718 Buttweld Pipe Fittings

Directional flow change in high-temperature, high-pressure, and chemically aggressive piping systems.

Choose Elbow when

- 45°, 90°, or 180° directional change is required

- Piping operates under extreme heat, oxidation, or corrosive chemical exposure

- Welded joints must withstand thermal cycling and high mechanical stress

- Used in aerospace, power generation, chemical processing, or nuclear systems

High-strength branch connections for extreme temperature and pressure applications.

Choose Tee when

- Equal or reducing branch connections are required

- High resistance to oxidation and stress corrosion cracking is critical

- Piping experiences vibration, pressure surges, or thermal expansion

- Used in chemical plants, turbine systems, or high-temperature process lines

Maintains proper pipe alignment while reducing diameter in high-temperature pipelines.

Choose Eccentric Reducer when

- Air or vapor pocket formation must be prevented

- Used in pump suction lines or horizontal high-temperature piping

- Thermal expansion and mechanical stress must be controlled

- Superior weld integrity under extreme heat is required

Uniform diameter transition for vertically installed or high-pressure piping systems.

Choose Concentric Reducer when

- Centered pipe alignment is essential

- Used in vertical, pressurized, or high-temperature piping

- Smooth and controlled flow transition is required

- Applied in heat exchangers, furnaces, or reactor piping

Facilitates dismantling using lap joint flanges in extreme service conditions.

Choose Long Stub End when

- Frequent inspection or maintenance is required

- High resistance to heat, corrosion, and pressure at flange joints is needed

- Large-diameter high-temperature piping is installed

- Used in chemical plants, power stations, or nuclear systems

Compact lap joint solution for space-limited high-temperature piping.

Choose Short Stub End when

- Space constraints exist in piping layout

- Economical flange connections are required

- Used in heat exchangers or chemical processing units

- High resistance to oxidation and thermal stress is essential

Seals pipe ends under extreme temperature and pressure conditions.

Choose Pipe Cap when

- Pipe ends must be securely closed

- Used for pressure testing or future expansion

- Leak-proof performance is required at elevated temperatures

- Exposed to oxidation, corrosion, or thermal cycling

Four-way flow distribution in complex high-temperature piping networks.

Choose Cross when

- Flow division into multiple directions is required

- Used in chemical processing or power generation piping

- High-strength, oxidation-resistant welded joints are needed

- Thermal fatigue resistance is critical

Large-radius flow change for minimal turbulence in extreme temperature pipelines.

Choose Pipe Bend when

- Gradual directional change is required

- Used in furnaces, heat exchangers, or power plants

- Reduced pressure loss and smooth flow are critical

- Long-term strength at high temperatures is required

Our Buttweld Pipe Fittings are manufactured using advanced processes and undergo extensive quality checks to ensure flawless weldability, durability, and long service life. Each fitting is thoroughly inspected using key NDT techniques such as radiographic testing (RT), ultrasonic testing (UT), hydrostatic testing, and visual/dimensional examination. We also perform detailed chemical composition analysis and mechanical property testing to ensure material compliance with strict industry standards.

Throughout the forming and welding stages, every buttweld fitting is monitored closely to eliminate defects such as misalignment, surface irregularities, and wall-thickness variations. This ensures perfect joint integrity and high-performance reliability in pipelines carrying high temperatures, pressures, and corrosive media. All our buttweld fittings fully comply with ASME, ASTM, MSS-SP, and related global specifications, making them a preferred choice for critical piping systems worldwide.

Request a Quote

Looking for high-quality Inconel 600/601/625/718 Buttweld Pipe Fittings Manufacturer and Exporter in India Buttweld Pipe Fittings? Get in touch with us today.

Contact Us