Premium Hastelloy C22/C276 Fasteners by Ratnadeep Steel & Engg. Co.

Ratnadeep Steel & Engg. Co. is a trusted manufacturer, exporter, and supplier of premium quality Hastelloy C22 and Hastelloy C276 Fasteners. Manufactured from high-performance nickel-chromium-molybdenum alloys using advanced production technology, our Hastelloy fasteners provide exceptional corrosion resistance, high strength, and long service life in highly aggressive environments. We offer Hastelloy fasteners in a wide range of sizes, standards, and specifications to meet diverse industrial and international project requirements.

Hastelloy C22/C276 fasteners are widely recognized for their outstanding resistance to pitting, crevice corrosion, stress corrosion cracking, and oxidizing or reducing chemicals. Hastelloy C22 delivers superior resistance in mixed chemical environments, while Hastelloy C276 is known for its excellent overall corrosion resistance in severe conditions. These qualities make Hastelloy alloy fasteners ideal for critical applications where safety, durability, and performance are non-negotiable.

With precise threading, smooth surface finish, and strict quality inspection, our Hastelloy C22 & C276 fasteners ensure reliable performance under high pressure, extreme temperatures, and harsh chemical exposure. They are extensively used in chemical processing, pollution control, oil & gas, power generation, heat exchangers, pulp & paper, and pharmaceutical industries. For high-performance, corrosion-resistant fastening solutions, Hastelloy fasteners are a dependable and long-lasting choice.

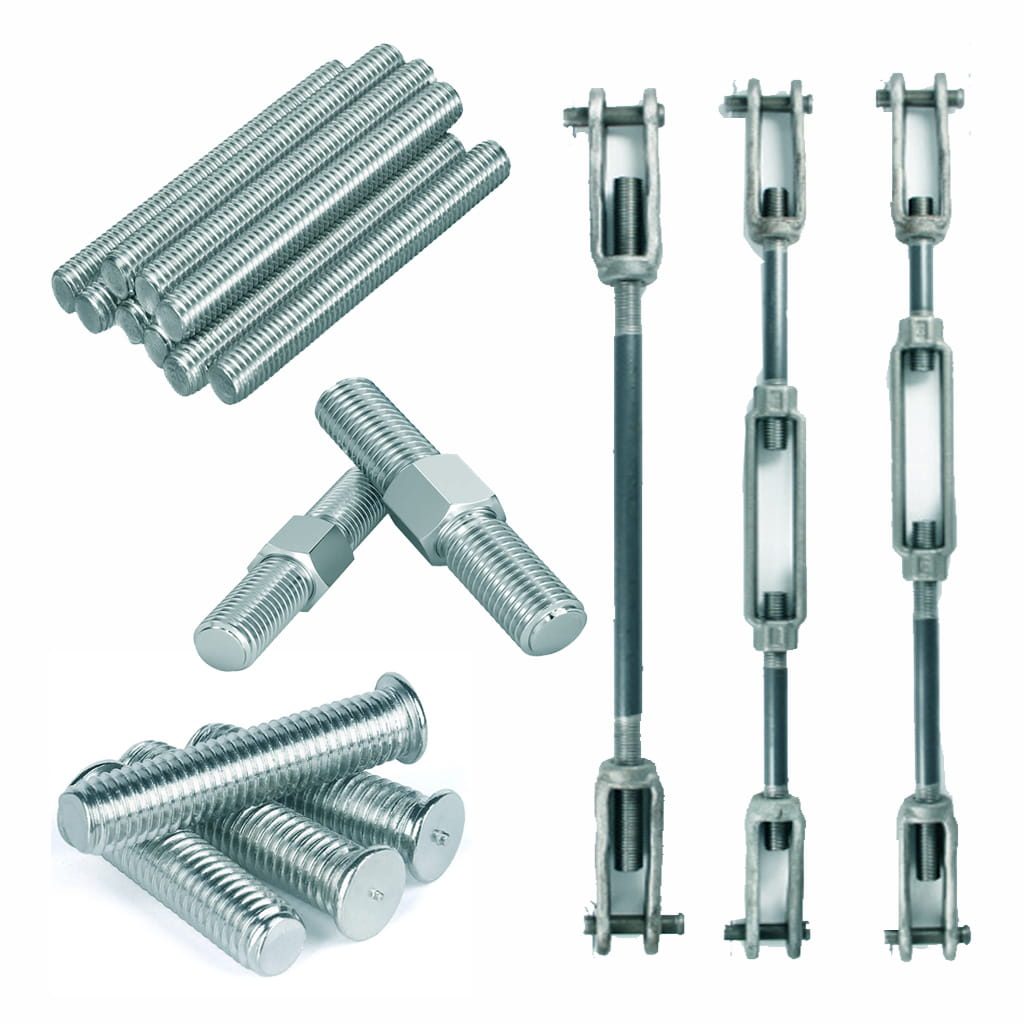

Our Range of Hastelloy Alloy C22 / C276 Industrial Fasteners

- Hastelloy C22 & C276 Hex, Heavy Hex and Lock Nuts

- UNS N06022 / N10276 Nickel-Chromium-Molybdenum Alloys

- DIN 2.4602 & 2.4819 Precision Machined Nuts

- Exceptional resistance to pitting, crevice & chemical corrosion

- ASTM B574 Hastelloy C22 & C276 Bolting

- Hex, Heavy Hex & Machine Bolt Configurations

- DIN 2.4602 / 2.4819 High-Performance Alloy Bolts

- Used in chemical processing, pollution control & reactors

- ASTM B574 Hastelloy C22 / C276 Screws

- Socket Head Cap, Button Head & Set Screws

- DIN 2.4602 / 2.4819 Precision Threaded Screws

- Outstanding resistance to acids and chloride environments

- Hastelloy C22 & C276 Plain, Spring & Dock Washers

- Split, Ogee & Custom Washer Designs

- Excellent load distribution in corrosive environments

- Ideal for chemical plants and offshore equipment

- ASTM B574 Hastelloy C22 / C276 Stud Bolts

- Single Ended, Double Ended & Fully Threaded Studs

- DIN 2.4602 / 2.4819 High-Strength Alloy Studs

- Used in pressure vessels, heat exchangers & flanges

- Hastelloy C22 & C276 Fully Threaded Rods

- ASTM B574 / UNS N06022 & N10276 Compliance

- Exceptional durability in aggressive chemical service

- Used in reactors, scrubbers & pollution control systems

C22 / C276 HASTELLOY ASTM B574 FASTENERS EQUIVALENT GRADES

| Standard | UNS | WNR. | EN | JIS | GOST | Other |

|---|---|---|---|---|---|---|

| Hastelloy C22 | N06022 | 2.4602 | NiCr21Mo14W | NW 6022 | — | — |

| Hastelloy C276 | N10276 | 2.4819 | NiMo16Cr15W | NW 0276 | ХН65МВУ | ЭП760 |

SPECIFICATION OF HASTELLOY ALLOY FASTENERS

| Standard | ASTM B574 / ASME SB574 |

|---|---|

| Dimension Standards | DIN, ISO, ASTM, JIS, BS, GB, IS & International |

| Size Range | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Length | 3 mm to 200 mm |

| Types | Nuts, Bolts, Screws, Studs, Hex Bolts, Heavy Hex Bolts, Socket Head Cap Screws, Hex Nuts, Lock Nuts, Washers, Spring Washers, Threaded Rods, U-Bolts, Anchor Bolts, Eye Bolts, Foundation Bolts, Structural Fasteners |

CHEMICAL COMPOSITION OF HASTELLOY C22 / C276 FASTENERS

| Grade | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr | W | V |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hastelloy C22 | Balance | 0.010 max | 12.5 – 14.5 | 0.50 max | 0.08 max | 2.0 – 6.0 | 0.02 max | 0.02 max | 2.5 max | 20.0 – 22.5 | 2.5 – 3.5 | 0.35 max |

| Hastelloy C276 | Balance | 0.01 max | 15.0 – 17.0 | 1.0 max | 0.08 max | 4.0 – 7.0 | 0.04 max | 0.03 max | 2.5 max | 14.5 – 16.5 | 3.0 – 4.5 | 0.35 max |

PHYSICAL PROPERTIES OF HASTELLOY C22 FASTENERS

| Density | 0.314 lb/in³ |

|---|---|

| Specific Gravity | 8.69 |

| Specific Heat (32–212°F) | 0.10 Btu/lb·°F |

| Melting Point | 2550°F |

| Thermal Conductivity | 70 Btu·in/hr·ft²·°F |

| Mean Thermal Expansion | 6.9 × 10⁻⁶ /°F |

| Modulus of Elasticity (Tension) | 29.9 × 10⁶ psi |

PHYSICAL PROPERTIES OF HASTELLOY C276 FASTENERS

| Property | Temp (°F) | British Units | Temp (°C) | Metric Units |

|---|---|---|---|---|

| Density | 72 | 0.321 lb/in³ | 22 | 8.89 g/cm³ |

| Melting Range | 2415–2500 | — | 1323–1371 | — |

| Mean Thermal Expansion | 75–200 | 6.2 µin/in·°F | 24–93 | 11.2 × 10⁻⁶ m/m·K |

| 75–400 | 6.7 µin/in·°F | 24–204 | 12.0 × 10⁻⁶ m/m·K | |

| 75–600 | 7.1 µin/in·°F | 24–316 | 12.8 × 10⁻⁶ m/m·K | |

| 75–800 | 7.3 µin/in·°F | 24–427 | 13.2 × 10⁻⁶ m/m·K | |

| 75–1000 | 7.4 µin/in·°F | 24–538 | 13.4 × 10⁻⁶ m/m·K | |

| Thermal Conductivity | -270 | 50 Btu·in/hr·ft²·°F | -168 | 7.2 W/m·K |

| -100 | 60 | -73 | 8.6 | |

| 0 | 65 | -18 | 9.4 | |

| 100 | 71 | 38 | 10.2 | |

| 200 | 77 | 93 | 11.1 | |

| Specific Heat (Room) | — | 0.102 Btu/lb·°F | — | 427 J/kg·K |

💡 Practical Difference in Use

Use Hastelloy C22 / C276 Fasteners when: maximum corrosion resistance is required in highly aggressive chemical, marine, and high-temperature environments. → Example: chemical reactors, flue gas scrubbers, offshore processing units, and acid handling systems.

Applications of Hastelloy C22 / C276 Fasteners

Hastelloy C22 and Hastelloy C276 fasteners (UNS N06022 / N10276) provide exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking in oxidizing and reducing media. Hastelloy C22 offers superior protection in mixed chemical environments, while Hastelloy C276 is known for its versatile corrosion resistance in severe conditions. These fasteners are ideal for critical applications requiring durability, safety, and long-term reliability.

- Chemical Processing: Reactors, pressure vessels, and heat exchangers.

- Pollution Control Systems: Scrubbers, ducts, and stack liners.

- Oil & Gas: Sour gas equipment and offshore processing systems.

When to Choose Hastelloy C22 / C276 Fasteners?

Hastelloy alloy fasteners are chosen for applications demanding extreme corrosion resistance and reliable performance in harsh chemical environments.

Choose Hastelloy C22 / C276 Fasteners when:

- Exposure to highly corrosive chemicals exists

- Resistance to pitting and crevice corrosion is critical

- High-temperature or high-pressure service is involved

- Both oxidizing and reducing media are present

- Long-term reliability in severe environments is essential

Industries That Use Hastelloy C22 / C276 Fasteners

Hastelloy C22 and C276 fasteners are widely used in industries requiring premium corrosion-resistant fastening solutions.

Engineered for highly aggressive chemicals.

Uses

Reactors, heat exchangers, and storage systems.

Why Hastelloy C22/C276?

Outstanding resistance to acids and mixed chemicals.

Reliable in corrosive exhaust environments.

Uses

FGD scrubbers, ducts, and stack liners.

Why Hastelloy C22/C276?

Excellent resistance to corrosive gases and condensates.

Suitable for sour and corrosive service.

Uses

Offshore equipment and processing units.

Why Hastelloy C22/C276?

Superior durability in harsh chemical and marine conditions.

Usage Guide for Hastelloy C22 / C276 Fasteners

Hastelloy C22 and Hastelloy C276 nuts provide exceptional resistance to aggressive chemicals, pitting, and crevice corrosion in critical environments.

Choose Hastelloy C22 / C276 Nuts when

- Used in highly corrosive chemical environments

- Resistance to oxidizing and reducing acids is required

- Protection against pitting and crevice corrosion is critical

- Long service life in severe conditions is expected

Hastelloy alloy bolts ensure secure fastening in chemical processing, oil & gas, and pollution control systems.

Choose Hastelloy C22 / C276 Bolts when

- Used in chemical plants and offshore facilities

- High-temperature or high-pressure service exists

- Exposure to strong acids or chlorides occurs

- Reliable corrosion-resistant fastening is essential

Hastelloy C22/C276 screws provide durable fastening in extremely corrosive and chemical-rich atmospheres.

Choose Hastelloy C22 / C276 Screws when

- Used in chemical reactors and processing equipment

- Continuous exposure to corrosive media exists

- High durability and corrosion resistance are required

- Critical safety and reliability standards must be met

Hastelloy washers help distribute load while resisting chemical attack and galvanic corrosion.

Choose Hastelloy C22 / C276 Washers when

- Used in chemical piping and flange assemblies

- Protection against galvanic and crevice corrosion is needed

- Exposure to acidic or chloride environments occurs

- Joint integrity in harsh conditions is critical

Hastelloy C22 and C276 stud bolts are ideal for high-pressure and highly corrosive service.

Choose Hastelloy C22 / C276 Stud Bolts when

- Used in reactors, pressure vessels, and scrubbers

- Severe chemical exposure exists

- High mechanical reliability is required

- Long-term performance in aggressive media is needed

Hastelloy threaded rods offer versatile, high-performance fastening in extreme chemical environments.

Choose Hastelloy C22 / C276 Threaded Rods when

- Custom-length fastening is required in chemical plants

- Used in pollution control and offshore systems

- Resistance to strong acids and chlorides is necessary

- Premium, long-life fasteners are preferred

Our Industrial Fasteners are manufactured using precision forging and machining processes to ensure excellent dimensional accuracy, strength, and long-term performance. Each fastener undergoes strict quality inspections, including visual and dimensional checks, tensile testing, hardness testing, and thread gauging to verify compliance with specified tolerances.

Comprehensive chemical composition analysis and mechanical property testing are carried out to confirm material integrity and standard conformity. Where required, additional NDT methods such as ultrasonic testing, magnetic particle inspection (MPI), or dye penetrant testing (DPT) are performed to detect surface or internal defects. Controlled forging, heat treatment, and threading processes eliminate issues such as cracks, laps, and thread imperfections.

All fasteners are manufactured and tested in accordance with international standards including ASTM, ASME, ISO, DIN, BS, and IS specifications. Engineered for reliable performance in high-pressure, high-temperature, and corrosive environments, our fasteners are widely used across oil & gas, petrochemical, power generation, construction, and heavy engineering industries.

Request a Quote

Looking for high-quality Hastelloy C22/C276 Fasteners? Get in touch with us today.

Contact Us