Overview

Carbon Steel Flanges are widely used for joining pipes, valves, pumps, and other equipment in oil & gas, petrochemical, power generation, and water treatment industries. They provide leak-proof connections, strength, and durability under high pressure and temperature.

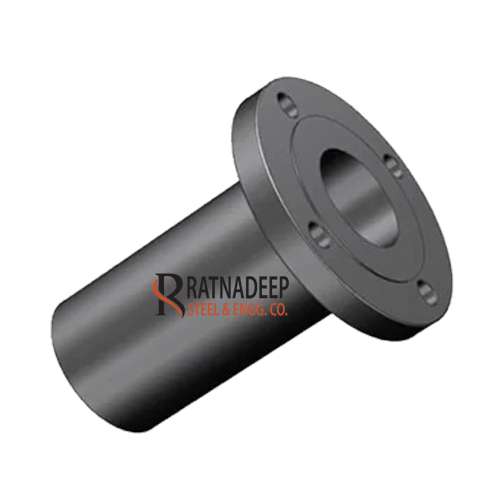

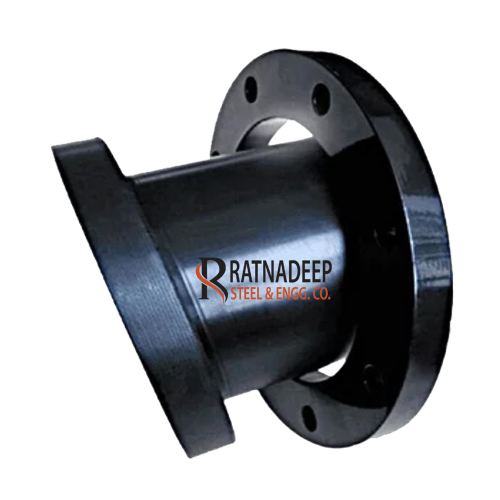

Types of Carbon Steel Flanges

Technical Specifications

| Standard | Size Range | Pressure Rating | Face Type |

|---|---|---|---|

| ASME / ANSI B16.5 & B16.47 | ⅛” to 48” | 150# to 2500# | RF, RTJ |

| DIN | DN10 to DN2000 | PN6 to PN400 | RF, FF |

| JIS | 10A to 1500A | 5K to 30K | FF, RF |

Material Grades: ASTM A105 / A694 F42 / F46 / F52 / F56 / F60 / F65 / F70 / A350 LF3 / A350 LF2 etc

Chemical & Mechanical Properties

- Tensile Strength: 485 MPa min

- Yield Strength: 250 MPa min

- Hardness: 170–207 HB

- Carbon Content: 0.25% max

Applications & Industries

Key Features & Benefits

- High durability & strength

- Corrosion-resistant coatings available

- Leak-proof connections

- Compatible with international standards

- Custom sizes & finishes available

Certifications & Quality Assurance

- ISO Certified

- PED & IBR Approved

- Third-party inspection (TPI) available

- Mill Test Certificates (MTC) provided

Frequently Asked Questions

What is the difference between Slip-On and Weld Neck Flanges?

Slip-On flanges slide over the pipe and are welded, while Weld Neck flanges are butt-welded for higher strength and durability.

Which grades of Carbon Steel are used?

Common grades include ASTM A105 and A350 LF2, suitable for high-pressure applications.

What do PN and Class ratings mean?

PN indicates pressure in bars (metric), while Class rating refers to ANSI/ASME pressure standards.

Request a Quote

Looking for high-quality Carbon Steel Flanges? Get in touch with us today.

Contact Us