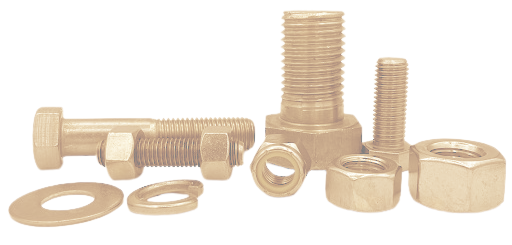

Our Range of High-Quality Industrial Fasteners

Our Industrial Fasteners are manufactured using precision forging and machining processes to ensure excellent dimensional accuracy, strength, and long-term performance. Each fastener undergoes strict quality inspections, including visual and dimensional checks, tensile testing, hardness testing, and thread gauging to verify compliance with specified tolerances.

Comprehensive chemical composition analysis and mechanical property testing are carried out to confirm material integrity and standard conformity. Where required, additional NDT methods such as ultrasonic testing, magnetic particle inspection (MPI), or dye penetrant testing (DPT) are performed to detect surface or internal defects. Controlled forging, heat treatment, and threading processes eliminate issues such as cracks, laps, and thread imperfections.

All fasteners are manufactured and tested in accordance with international standards including ASTM, ASME, ISO, DIN, BS, and IS specifications. Engineered for reliable performance in high-pressure, high-temperature, and corrosive environments, our fasteners are widely used across oil & gas, petrochemical, power generation, construction, and heavy engineering industries.

Request a Quote

Looking for high-quality Fasteners? Get in touch with us today.

Contact Us