Carbon Steel SAW / LSAW / HSAW Pipes & Tubes

Ratnadeep Steel & Engg. Co. is a trusted manufacturer, supplier, and exporter of high-quality Carbon Steel SAW, LSAW, and HSAW Pipes & Tubes, available at competitive prices. These pipes are manufactured using superior-grade raw materials and advanced machinery to ensure exceptional strength, reliability, and dimensional accuracy. All our products conform to national and international quality standards, making us a preferred choice among industries worldwide. SAW (Submerged Arc Welded) pipes are produced using a welding process in which the arc is submerged under flux, ensuring high-quality weld joints and smooth internal surfaces. The main types of SAW pipes include LSAW (Longitudinal Submerged Arc Welded) and HSAW (Helical Submerged Arc Welded) pipes, which differ based on the welding orientation. In LSAW pipes, the steel plate is rolled and welded longitudinally along its length, providing superior strength and uniformity—ideal for high-pressure oil and gas transportation. On the other hand, HSAW or spiral welded pipes are manufactured by spirally welding steel coils in a helix form, resulting in enhanced flexibility and the ability to produce larger diameters. Ratnadeep Steel & Engg. Co. offers a wide range of specifications including API 5L Carbon Steel LSAW Pipe, Carbon Steel SAW Pipes, API 5L Spiral HSAW Line Pipes, and CS Submerged Arc Welded Tubes, catering to diverse applications across oil & gas, water transmission, petrochemical, and infrastructure industries. With a strong focus on quality and performance, Ratnadeep Steel & Engg. Co. continues to deliver carbon steel SAW, LSAW, and HSAW pipes that ensure durability, corrosion resistance, and reliability under the most demanding operating conditions.

Specification of Carbon Steel SAW/LSAW/HSAW Pipes & Tubes

| Specification | Details |

|---|---|

| Specification | ASTM A671/ 672 GR.B/ CB/ CC 60/ 65/ 70 CL 12/ 22/ 32 IS 3589 GR.450 |

| Size | 1/2” NB to 36” NB |

| Wall Thickness | 0.5mm to 85mm |

| Type | Seamless |

| Form | Round, Square, Rectangular, Oval, Hydraulic Etc |

| Length | Single Random, Double Random & Cut Length |

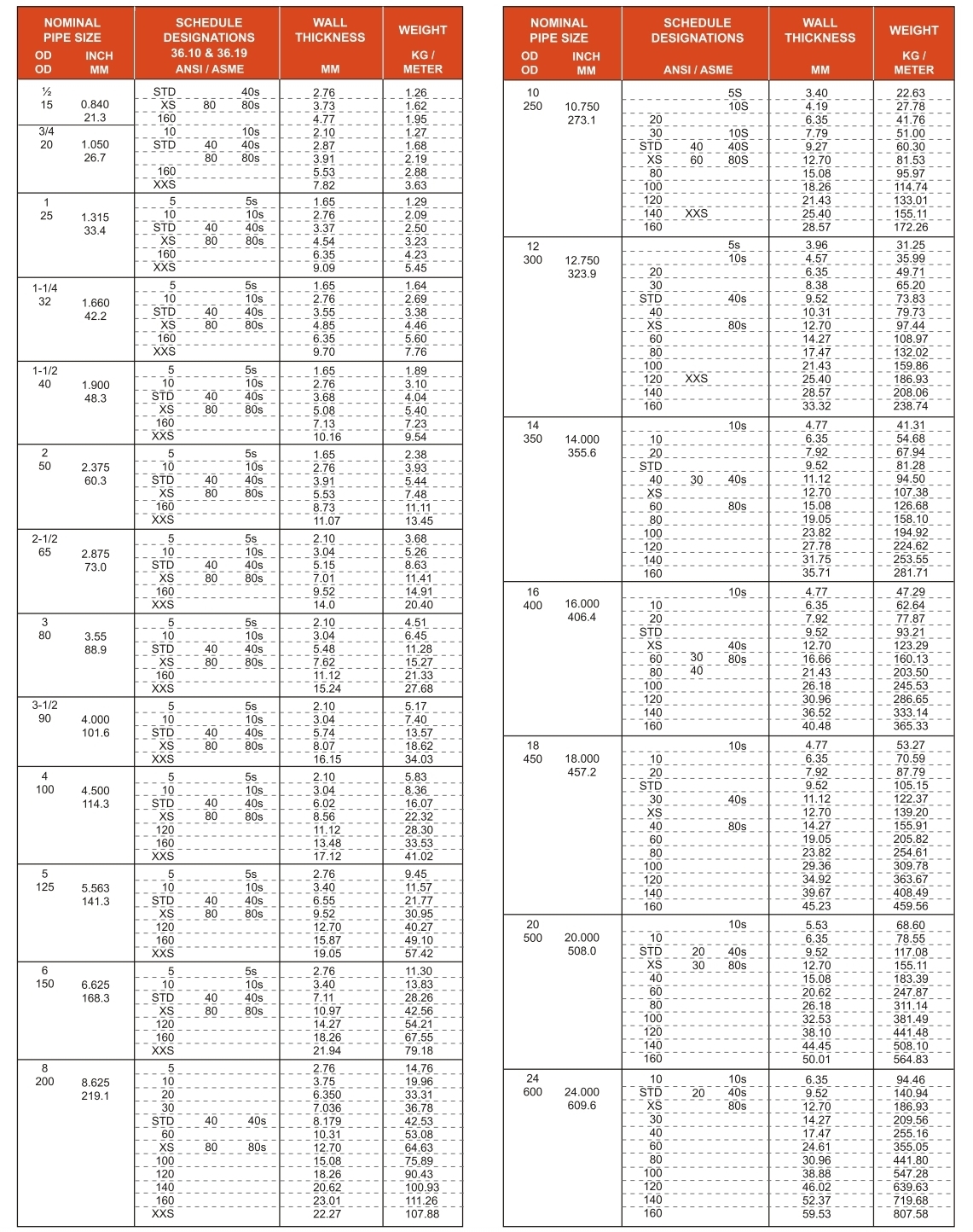

| Schedules | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Inspection, Test Reports | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports, India Boiler Regulations (IBR) Test Certificate |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| End | Plain End, Beveled End, Treaded |

| Surface | Black painting, varnish paint, anti rust oil, hot galvanized, cold galvanized, 3PE |

CARBON STEEL PIPE & TUBES SCHEDULE DIMENSIONS WALL THICKNESS, WT./MTR. (KG)

Click to expand ▼

MECHANICAL PROPERTIES OF CARBON STEEL PIPES AND TUBES

| Specification | Tensile Strength | Yield Strength | Elongation 50mm MIN Longitudinal |

SPECIFIC REQUIREMENT | ||

|---|---|---|---|---|---|---|

| Mpa | Mpa | Mpa | Mpa | |||

| ASTM A 53 | 331MIN | 207 MIN | 36 | Cr Mo Cu Ni Va 0.40 0.15 0.40 0.40 0.08 |

||

| 413MIN | 240MIN | 29.5 | ||||

| 330MIN | 205MIN | 35/28 | ||||

| 415MIN | 240MIN | 30/22 | ||||

| 485MIN | 275MIN | 30/22 | ||||

| ASTM A 333/1 | 380MIN | 205MIN | 25/20 | Impact AS-50F FOR 40X10J/18/14 -50F 40X10J/18/14 90 HRB MAX |

||

| 415MIN | 240MIN | 30/22 | ||||

| 380MIN | 205MIN | 35/28 | ||||

| 415MIN | 240MIN | 30/22 | ||||

Applications and Uses of Carbon Steel SAW / LSAW / HSAW Pipes & Tubes

Carbon Steel SAW, LSAW, and HSAW pipes & tubes are widely used for long-distance transportation of oil, gas, water and petroleum products. Their excellent mechanical strength, uniform wall thickness and high-quality weld integrity make them suitable for high-pressure and high-temperature services. Durable, cost-effective and reliable, these pipes are preferred for critical infrastructure, energy and marine applications.

Common Applications:

- Oil & gas transportation pipelines for crude oil, natural gas and petroleum products

- Municipal and industrial water supply, drainage and irrigation systems

- Structural and mechanical uses in construction, bridges and offshore platforms

- High-pressure process lines in refineries, petrochemical and chemical plants

- Offshore and onshore pipeline projects requiring large diameters and robust joints

- Piling, foundation and marine engineering applications

- Energy and power transmission lines for long-distance fluid transfer

Industries Using SAW / LSAW / HSAW Pipes:

- Oil & Gas Industry

- Petrochemical and Refinery Plants

- Power Generation and Energy Sector

- Offshore & Marine Engineering

- Water Treatment and Desalination Projects

- Construction, Infrastructure & Civil Engineering

- Mechanical, Process and Structural Engineering Sectors

At Ratnadeep Steel & Engg. Co., we supply high-grade SAW, LSAW and HSAW pipes & tubes conforming to international standards (e.g., API 5L, ASTM A671, ASTM A672), ensuring durability, traceability and consistent performance for demanding industrial projects.

Request a Quote

Looking for premium Carbon Steel SAW, LSAW and HSAW Pipes & Tubes? Contact us today to get the best prices.

Contact Us