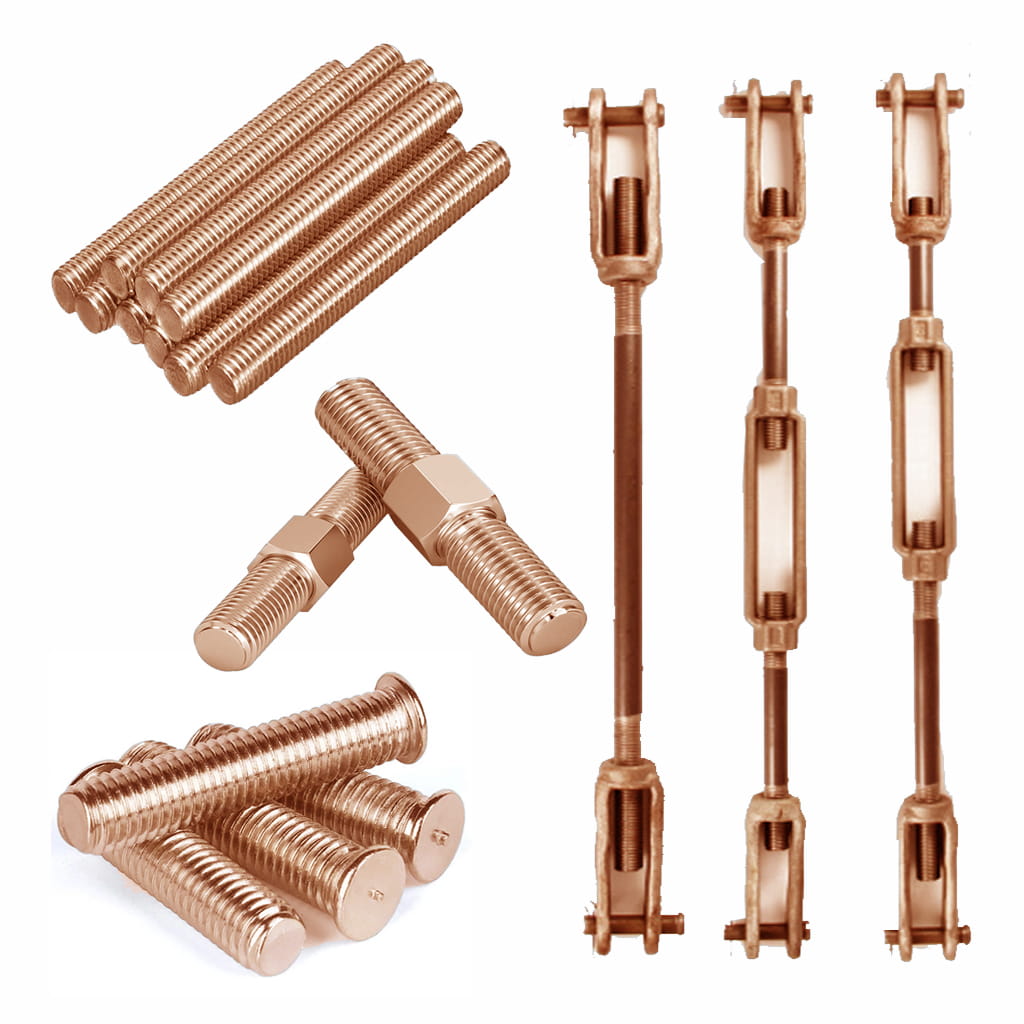

Premium Copper Nickel 90/10 Fasteners by Ratnadeep Steel & Engg. Co.

Ratnadeep Steel & Engg. Co. is a leading manufacturer, exporter, and supplier of high-quality Copper Nickel 90/10 Fasteners. Manufactured from premium copper-nickel alloy using advanced production processes, our fasteners offer excellent corrosion resistance, good mechanical strength, and long service life in marine and coastal environments.

Copper Nickel 90/10 fasteners are widely preferred for their excellent resistance to seawater corrosion, biofouling, and general marine atmospheric conditions. With a balanced copper-to-nickel composition, these fasteners provide reliable corrosion protection and good fabricability, making them suitable for moderate marine and offshore service conditions where cost-effectiveness and durability are essential.

Designed with accurate threading, clean surface finish, and tight tolerances, our Copper Nickel 90/10 fasteners ensure consistent performance under moisture exposure, thermal cycling, and mild chemical environments. They are commonly used in shipbuilding, seawater pipelines, desalination plants, heat exchangers, condensers, coastal infrastructure, and marine engineering applications.

Our Range of Copper Nickel Alloy 90/10 Industrial Fasteners

- Copper Nickel 90/10 Hex, Heavy Hex & Lock Nuts

- UNS C70600 Cu-Ni Precision Machined Nuts

- DIN & ASTM B151 compliant nut standards

- Excellent resistance to seawater corrosion

- ASTM B151 Copper Nickel 90/10 Bolting

- Hex, Heavy Hex & Machine Bolts

- UNS C70600 for marine & coastal use

- Good strength with excellent corrosion resistance

- Cu-Ni 90/10 Socket Head & Cap Screws

- Hex Head, Set Screws & Custom Screws

- Manufactured as per ASTM B151 & DIN norms

- Ideal for marine and seawater systems

- Cu-Ni 90/10 Plain, Spring & Dock Washers

- Split, Ogee & Custom Washer Types

- Prevents galvanic corrosion in joints

- Designed for marine-grade applications

- ASTM B151 Copper Nickel 90/10 Stud Bolts

- Single Ended, Double Ended & Fully Threaded

- UNS C70600 for flange and piping systems

- Widely used in desalination and shipbuilding

- Cu-Ni 90/10 Fully Threaded & Cut-Length Rods

- ASTM B151 / UNS C70600 Compliance

- Excellent durability in seawater conditions

- Used in marine, coastal & heat exchanger systems

COPPER NICKEL 90/10 ASTM B151 FASTENERS EQUIVALENT GRADES

| Standard | UNS | WNR. |

|---|---|---|

| Copper Nickel 90/10 | C70600 | 2.0872 |

SPECIFICATION OF COPPER NICKEL 90/10 FASTENERS

| Specification | ASTM B151 / ASME SB151 |

|---|---|

| Dimension Standards | DIN, ISO, ASTM, JIS, BS, GB, IS and all International Standards |

| Size Range | M3 – M56 | 3/6" to 2" | Custom Sizes |

| Length | 3 mm to 200 mm |

| Types | Nuts, Bolts, Screws, Sockets, Studs, Hex Set Screws, Socket Screws, Cap Screws, Pan Head Screws, Machine Screws, Socket Head Cap Screws, Allen Cap Screws, Wing Screws, Washers, Spring Washers, Anchors, Marine Anchors, Hexagon Nuts, Hex Nuts, Coupling Nuts, Hex Domed Cap Nuts, Square Nuts, Stud Bolts, Hex Head Bolts, Socket Hexagon Head Screw Anchor Bolts, U-Bolts, J-Bolts, Mushroom Head Square Neck Bolts, T-Head Bolts, Eye Bolts, Foundation Bolts, Structural Bolts |

CHEMICAL COMPOSITION OF COPPER NICKEL 90/10 INDUSTRIAL FASTENERS

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

|---|---|---|---|---|---|---|

| Cu-Ni 90/10 | 88.6 min | 1.0 max | 0.05 max | 9 – 11 | 1.8 max | 1.0 max |

MECHANICAL PROPERTIES OF ASME SB151 COPPER NICKEL 90/10 BOLTS & NUTS

| Properties | Metric | Imperial |

|---|---|---|

| Tensile Strength, Ultimate | 303 – 414 MPa | 43,900 – 60,000 psi |

| Tensile Strength, Yield (Temperature Dependent) | 110 – 393 MPa | 16,000 – 57,000 psi |

| Elongation at Break (in 254 mm) | 42% | 42% |

| Machinability (UNS C36000 = 100%) | 20% | 20% |

| Shear Modulus | 52.0 GPa | 7,540 ksi |

| Poisson’s Ratio | 0.34 | 0.34 |

| Elastic Modulus | 140 GPa | 20,300 ksi |

PHYSICAL PROPERTIES OF COPPER NICKEL 90/10 FASTENERS

| Property | Metric | Imperial |

|---|---|---|

| Density | 8.94 g/cm³ | 0.323 lb/in³ |

💡 Practical Difference in Use

Use Copper Nickel 90/10 Fasteners when: reliable corrosion resistance in seawater is required for moderate marine and coastal applications with lower flow velocities. → Example: seawater pipelines, desalination plants, shipboard systems, and coastal infrastructure.

Applications of Copper Nickel 90/10 Fasteners

Copper Nickel 90/10 fasteners (UNS C70600) provide excellent resistance to seawater corrosion, biofouling, and stress corrosion. These fasteners are widely used in marine and desalination applications where moderate strength and long-term reliability are required.

- Seawater Systems: Piping, valves, and fittings.

- Desalination Plants: RO units, intake systems, and brine handling.

- Marine Equipment: Shipboard piping and cooling systems.

When to Choose Copper Nickel 90/10 Fasteners?

Copper Nickel 90/10 fasteners are selected for applications requiring good seawater corrosion resistance with cost-effective performance.

Choose Copper Nickel 90/10 Fasteners when:

- Moderate seawater exposure conditions exist

- Resistance to biofouling is required

- Cost efficiency is a priority over higher strength

- Lower flow velocity systems are involved

- Proven marine alloy performance is needed

Industries That Use Copper Nickel 90/10 Fasteners

Copper Nickel 90/10 fasteners are commonly used in industries exposed to seawater and coastal environments.

Reliable in saline water processing.

Uses

RO plants, intake piping, and pumps.

Why Copper Nickel 90/10?

Excellent corrosion resistance with proven durability.

Designed for marine atmospheres.

Uses

Shipboard piping, coastal structures.

Why Copper Nickel 90/10?

Resists seawater corrosion and biofouling.

Suitable for cooling water systems.

Uses

Condensers and heat exchangers.

Why Copper Nickel 90/10?

Stable performance in seawater cooling circuits.

Usage Guide for Copper Nickel 90/10 Fasteners

Copper Nickel 90/10 nuts offer dependable corrosion resistance for moderate marine and coastal environments.

Choose Copper Nickel 90/10 Nuts when

- Used in seawater or coastal installations

- Moderate corrosion resistance is sufficient

- Cost-effective marine fasteners are required

- Long service life in saline environments is expected

Copper Nickel 90/10 bolts provide reliable fastening in seawater and desalination systems.

Choose Copper Nickel 90/10 Bolts when

- Used in desalination plants and seawater pipelines

- Lower flow velocities are involved

- Resistance to seawater corrosion is required

- Economical marine alloy performance is preferred

Copper Nickel 90/10 screws ensure stable fastening in marine and coastal applications.

Choose Copper Nickel 90/10 Screws when

- Used in shipboard and coastal equipment

- Exposure to seawater spray or humidity is expected

- Moderate mechanical strength is sufficient

- Proven marine alloy reliability is required

Copper Nickel 90/10 washers help distribute load while resisting marine corrosion.

Choose Copper Nickel 90/10 Washers when

- Used in seawater piping and flange joints

- Protection against galvanic corrosion is required

- Moderate chloride resistance is sufficient

- Joint stability in marine service is important

Copper Nickel 90/10 stud bolts are suitable for moderate-pressure marine and desalination systems.

Choose Copper Nickel 90/10 Stud Bolts when

- Used in seawater piping and desalination plants

- Moderate corrosion resistance is acceptable

- Lower flow and pressure conditions exist

- Cost-effective performance is a priority

Copper Nickel 90/10 threaded rods provide versatile fastening for marine and coastal structures.

Choose Copper Nickel 90/10 Threaded Rods when

- Custom-length fastening is needed in marine installations

- Used in coastal infrastructure and seawater systems

- Moderate corrosion resistance is sufficient

- Long-term reliability with controlled cost is required

Our Industrial Fasteners are manufactured using precision forging and machining processes to ensure excellent dimensional accuracy, strength, and long-term performance. Each fastener undergoes strict quality inspections, including visual and dimensional checks, tensile testing, hardness testing, and thread gauging to verify compliance with specified tolerances.

Comprehensive chemical composition analysis and mechanical property testing are carried out to confirm material integrity and standard conformity. Where required, additional NDT methods such as ultrasonic testing, magnetic particle inspection (MPI), or dye penetrant testing (DPT) are performed to detect surface or internal defects. Controlled forging, heat treatment, and threading processes eliminate issues such as cracks, laps, and thread imperfections.

All fasteners are manufactured and tested in accordance with international standards including ASTM, ASME, ISO, DIN, BS, and IS specifications. Engineered for reliable performance in high-pressure, high-temperature, and corrosive environments, our fasteners are widely used across oil & gas, petrochemical, power generation, construction, and heavy engineering industries.

Request a Quote

Looking for high-quality Copper Nickel 90/10 Fasteners? Get in touch with us today.

Contact Us