High Quality Carbon Steel Seamless & ERW Pipes & Tubes

Seamless • ERW • ASTM A106 GR/B • ASTM A53 GR/B • ASTM A333 GR/6 • ASTM A671/672

Get a QuoteCarbon Steel Seamless & ERW Pipes and Tubes

Ratnadeep Steel & Engg. Co. is one of the leading manufacturers, suppliers, and exporters of Carbon Steel Seamless and ERW Pipes & Tubes in India. We offer a complete range of carbon steel pipes in various sizes, thicknesses, and specifications to meet the diverse needs of our clients across industries. All our products are manufactured using superior-grade raw materials and advanced production technology to ensure excellent quality, strength, and performance. Carbon Steel Seamless Pipes are produced from solid round billets, which are heated and then pierced to form a hollow tube structure. This process results in a uniform, joint-free pipe that offers excellent pressure resistance and durability—ideal for high-temperature and high-pressure applications. ERW (Electric Resistance Welded) Pipes, on the other hand, are manufactured by rolling metal sheets and welding them longitudinally across their length. This creates a visible weld seam, distinguishing them from seamless pipes. We manufacture and supply carbon steel pipes that comply with multiple international standards such as ASTM A106 Grade B, ASTM A53 Grade B, ASTM A333 Grade 6, ASTM A671, ASTM A672, and other equivalent specifications. These pipes are available in both welded and seamless forms and are produced using Plug Mill and CPE (Cross Roll Piercing and Elongation) technologies for precise dimensional accuracy and superior surface finish. At Ratnadeep Steel & Engg. Co., we ensure that every pipe undergoes rigorous quality testing, including hardness, chemical composition, hydrostatic, and dimensional tests, to guarantee compliance with the highest standards. Our products are carefully packed in wooden boxes, hexagonal bundles, steel crates, or custom packaging to ensure safe delivery worldwide.

Specification of Carbon Steel SAW/LSAW/HSAW Pipes & Tubes

| Specification | Details |

|---|---|

| Specification | ASTM A106 GR A/B , ASTM A105, ASTM A53 GR A/B, API 5L / DIN1626, DIN1629, DIN17175, DIN 2448, JIS G3452, JIS G3454, JIS G3455, JIS G3456, JIS G3457, JIS G3 |

| Size | 1/2” NB to 36” NB |

| Wall Thickness | 0.5mm to 85mm |

| Type | Seamless |

| Form | Round, Square, Rectangular, Oval, Hydraulic Etc |

| Length | Single Random, Double Random & Cut Length |

| Schedules | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Inspection, Test Reports | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports, India Boiler Regulations (IBR) Test Certificate |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| End | Plain End, Beveled End, Treaded |

| Surface | Black painting, varnish paint, anti rust oil, hot galvanized, cold galvanized, 3PE |

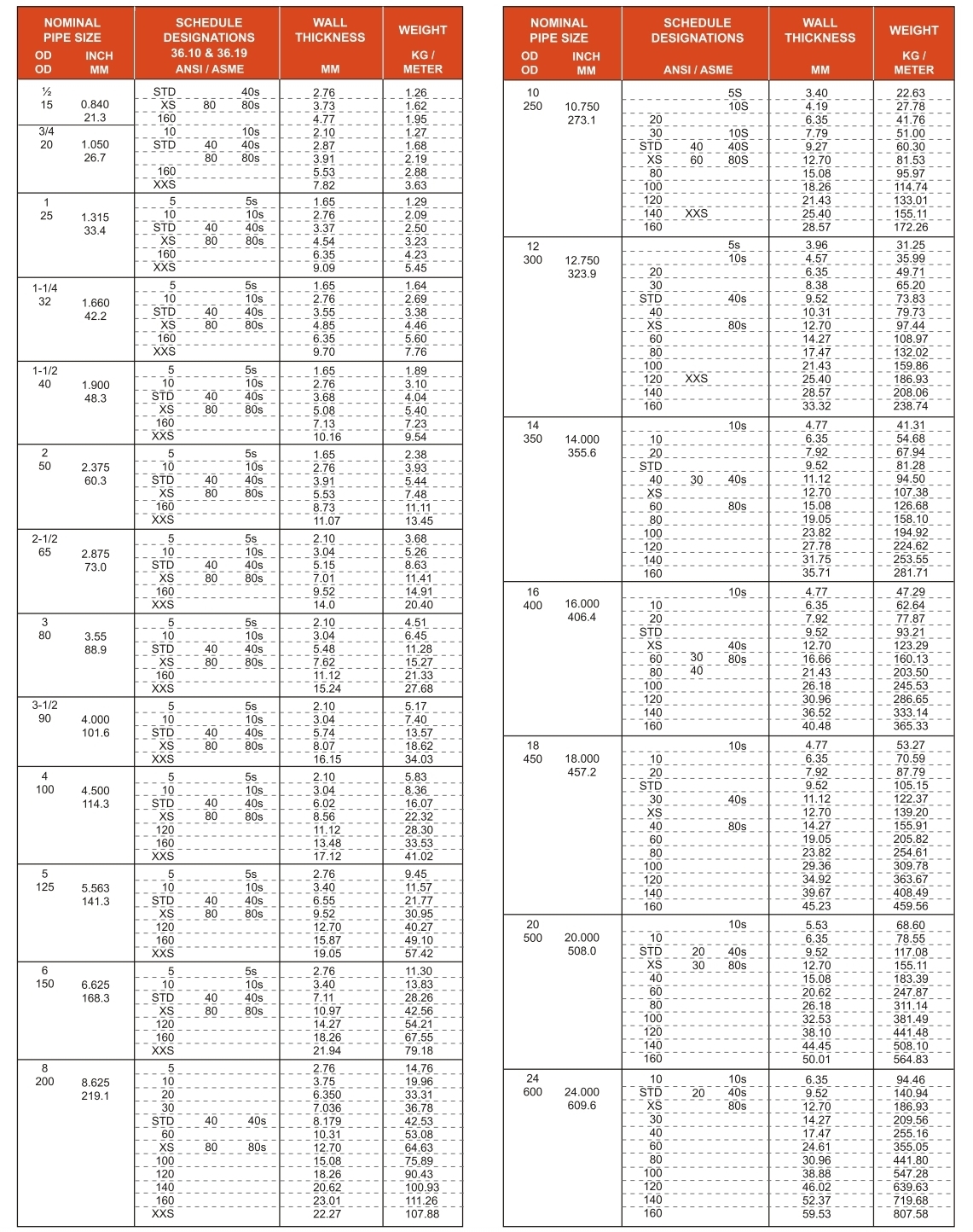

CARBON STEEL PIPE & TUBES SCHEDULE DIMENSIONS WALL THICKNESS, WT./MTR. (KG)

Click to expand ▼

CHEMICAL COMPOSITION OF CARBON STEEL PIPES AND TUBES

| Chemical Composition [%] | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specification | Grade | C | Mn | P Max. |

S Max. |

Si | Cr | Mo | Cu Max. |

Ni Max. |

V Max. |

|||||

| Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | |||||||

| HYDROCARBON PROCESS INDUSTRY / STRUCTURAL / PRESSURE VESSEL TUBES | ||||||||||||||||

| ASTM A-53 | A | – | 0.25 | – | 0.95 | 0.050 | 0.045 | – | – | – | 0.40 | – | 0.15 | 0.40 for S | 0.40 | 0.08 |

| B | – | 0.30 | – | 1.20 | 0.050 | 0.045 | – | – | – | 0.40 | – | 0.15 | 0.40 for S | 0.40 | 0.08 | |

| ASTM A-106 | A | – | 0.25 | 0.27 | 0.93 | 0.035 | 0.035 | 0.10 | – | – | 0.40 | – | 0.15 | 0.40 | 0.40 | 0.08 |

| B | – | 0.30 | 0.29 | 1.06 | 0.035 | 0.035 | 0.10 | – | – | 0.40 | – | 0.15 | 0.40 | 0.40 | 0.08 | |

| C | – | 0.35 | 0.29 | 1.06 | 0.035 | 0.035 | 0.10 | – | – | 0.40 | – | 0.15 | 0.40 | 0.40 | 0.08 | |

| ASTM A333 & A334 | 1 | – | 0.30 | 0.40 | 1.06 | 0.025 | 0.025 | – | 0.10 | – | – | – | – | – | – | – |

| 6 | – | 0.30 | 0.29 | 1.06 | 0.025 | 0.025 | – | 0.10 | – | – | – | – | – | – | – | |

CHEMICAL COMPOSITION OF SEAMLESS COLD DRAWN PRECISION STEEL TUBES FOR MECHANICAL APPLICATIONS / HYDRAULIC / PNEUMATIC POWER SYSTEMS

| Chemical Composition [%] | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specification | Grade | C | Mn | P Max. |

S Max. |

Si | Cr | Mo | Cu Max. |

Ni Max. |

V Max. |

|||||

| Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | |||||||

| SEAMLESS COLD DRAWN PRECISION STEEL TUBES FOR MECHANICAL APPLICATIONS / HYDRAULIC / PNEUMATIC POWER SYSTEMS | ||||||||||||||||

| EN 10305-1 / EN 10305-4 | E 235 E 355 |

– – |

0.17 0.22 |

– – |

1.2 1.6 |

0.025 0.025 |

0.025 0.025 |

– – |

0.35 0.55 |

– – |

– – |

– – |

– – |

– – |

– – |

0.02 0.02 |

| EN 10216-1 | P195 TR1 P235 TR1 |

– – |

0.13 0.16 |

– – |

0.7 1.2 |

0.025 0.025 |

0.02 0.02 |

– – |

0.35 0.35 |

– – |

0.3 0.3 |

– – |

0.08 0.08 |

0.3 0.3 |

0.3 0.3 |

– – |

| EN 10216-2 | P235 GH | – | 0.16 | – | 1.2 | 0.025 | 0.02 | – | 0.35 | – | 0.3 | – | 0.08 | 0.3 | 0.3 | 0.02 |

| DIN 2391 | St – 45 St – 45 St – 52 |

– – – |

0.17 0.21 0.22 |

0.40 0.40 – |

– – 1.6 |

0.025 0.025 0.025 |

0.025 0.025 0.025 |

– – – |

0.35 0.35 0.55 |

– – – |

– – – |

– – – |

– – – |

– – – |

– – – |

– – – |

| ASTM A-519 | SAE 1010 | 0.08 | 0.13 | 0.30 | 0.60 | 0.040 | 0.050 | – | – | – | – | – | – | – | – | – |

| SAE 1018 | 0.15 | 0.20 | 0.60 | 0.90 | 0.040 | 0.050 | – | – | – | – | – | – | – | – | – | |

| SAE 1026 | 0.22 | 0.28 | 0.60 | 0.90 | 0.040 | 0.050 | – | – | – | – | – | – | – | – | – | |

| SAE 1035 | 0.32 | 0.38 | 0.60 | 0.90 | 0.040 | 0.050 | – | – | – | – | – | – | – | – | – | |

| SAE 1040 | 0.37 | 0.44 | 0.60 | 0.90 | 0.040 | 0.050 | – | – | – | – | – | – | – | – | – | |

| SAE 1518 | 0.15 | 0.21 | 1.10 | 1.40 | 0.040 | 0.050 | – | – | – | – | – | – | – | – | – | |

| SAE 1541 | 0.36 | 0.44 | 1.35 | 1.65 | 0.040 | 0.050 | – | – | – | – | – | – | – | – | – | |

| SAE 4130 | 0.28 | 0.33 | 0.40 | 0.60 | 0.040 | 0.040 | 0.15 | 0.35 | 0.80 | 1.10 | 0.15 | 0.25 | – | – | – | |

| Chemical Composition [%] | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specification | Grade | C | Mn | P Max. | S Max. | Si | Cr | Mo | Cu Max. | Ni Max. | V Max. | |||||

| Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | |||||||

| BOILER/HEAT EXCHANGER/SUPERHEATER & CONDENSER TUBES | ||||||||||||||||

| ASTM A179 | – | 0.06 | 0.18 | 0.27 | 0.63 | 0.035 | 0.035 | – | – | – | – | – | – | – | – | – |

| ASTM A192 | – | 0.06 | 0.18 | 0.27 | 0.63 | 0.035 | 0.035 | – | 0.25 | – | – | – | – | – | – | – |

| ASTM A 210 | A-1 | – | 0.27 | 0.29 | 0.93 | 0.035 | 0.035 | 0.1 | – | – | – | – | – | – | – | – |

| C | – | 0.35 | 0.29 | 1.06 | 0.035 | 0.035 | 0.1 | – | – | – | – | – | – | – | – | |

| ASTM A 213 | T-11 | 0.05 | 0.15 | 0.3 | 0.6 | 0.025 | 0.025 | 0.5 | 1 | 1 | 1.5 | 0.44 | 0.65 | – | – | – |

| T-12 | 0.05 | 0.15 | 0.3 | 0.61 | 0.025 | 0.025 | 0.5 | 0.5 | 0.8 | 1.25 | 0.44 | 0.65 | – | – | – | |

| T-22 | 0.05 | 0.15 | 0.3 | 0.6 | 0.025 | 0.025 | – | 0.5 | 1.9 | 2.6 | 0.87 | 1.13 | – | – | – | |

| ASTM A 335 | P-11 | 0.05 | 0.15 | 0.3 | 0.6 | 0.025 | 0.025 | 0.5 | 1 | 1 | 1.5 | 0.44 | 0.65 | – | – | – |

| P-12 | 0.05 | 0.15 | 0.3 | 0.61 | 0.025 | 0.025 | 0.5 | 0.5 | 0.8 | 1.25 | 0.44 | 0.65 | – | – | – | |

| P-22 | 0.05 | 0.15 | 0.3 | 0.6 | 0.025 | 0.025 | – | 0.5 | 1.9 | 2.6 | 0.87 | 1.13 | – | – | – | |

| BS 3059 Pt I | 320 | – | 0.16 | 0.3 | 0.7 | 0.04 | 0.04 | 0.1 | 0.35 | – | – | – | – | – | – | – |

| BS 3059 Pt II | 622-490 | 0.08 | 0.15 | 0.4 | 0.7 | 0.03 | 0.03 | – | 0.5 | 2 | 2.5 | 0.9 | 1.2 | – | – | – |

| DIN 1629 | St- 37.0 | – | 0.17 | – | – | 0.04 | 0.04 | – | – | – | – | – | – | – | – | – |

| St-52 | – | 0.22 | – | – | 0.04 | 0.035 | – | – | – | – | – | – | – | – | – | |

| DIN 17175 | St – 35.8 | – | 0.17 | 0.4 | 0.8 | 0.4 | 0.4 | 0.1 | 0.35 | – | – | – | – | – | – | – |

| St – 45.8 | – | 0.22 | 0.4 | 1.2 | 0.4 | 0.4 | 0.1 | 0.35 | – | – | – | – | – | – | – | |

| RAILWAYS | ||||||||||||||||

| IS:1239 Pt I | – | – | – | – | – | 0.05 | 0.05 | – | – | – | – | – | – | – | – | – |

| IS:1161 | YST-210 | – | 0.12 | – | 0.6 | 0.04 | 0.04 | – | – | – | – | – | – | – | – | – |

| YST-240 | – | 0.16 | – | 1.2 | 0.04 | 0.04 | – | – | – | – | – | – | – | – | – | |

| YST-310 | – | 0.25 | – | 1.3 | 0.04 | 0.04 | – | – | – | – | – | – | – | – | – | |

MECHANICAL PROPERTIES OF CARBON STEEL PIPES AND TUBES

| Specification | Tensile Strength | Yield Strength | Elongation 50mm MIN Longitudinal |

SPECIFIC REQUIREMENT | ||

|---|---|---|---|---|---|---|

| Mpa | Mpa | Mpa | Mpa | |||

| ASTM A 53 | 331MIN | 207 MIN | 36 | Cr Mo Cu Ni Va 0.40 0.15 0.40 0.40 0.08 |

||

| 413MIN | 240MIN | 29.5 | ||||

| 330MIN | 205MIN | 35/28 | ||||

| 415MIN | 240MIN | 30/22 | ||||

| 485MIN | 275MIN | 30/22 | ||||

| ASTM A 333/1 | 380MIN | 205MIN | 25/20 | Impact AS-50F FOR 40X10J/18/14 -50F 40X10J/18/14 90 HRB MAX |

||

| 415MIN | 240MIN | 30/22 | ||||

| 380MIN | 205MIN | 35/28 | ||||

| 415MIN | 240MIN | 30/22 | ||||

Request a Quote

Looking for premium Carbon Steel Seamless & ERW Pipes & Tubes? Contact us today to get the best prices.

Contact Us