Overview

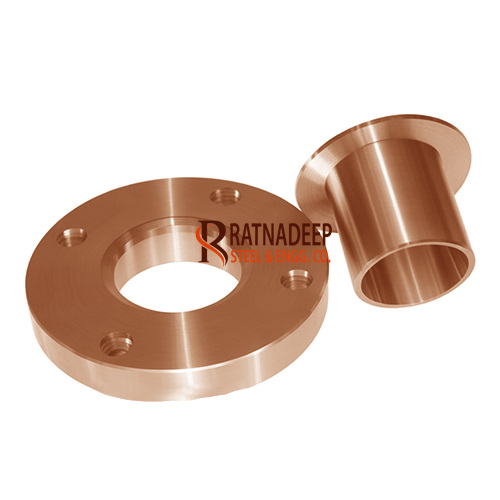

Bronze Flanges are known for excellent corrosion resistance, especially in seawater and chemical environments. They are commonly used in marine, chemical, and industrial piping systems where long-lasting performance is required.

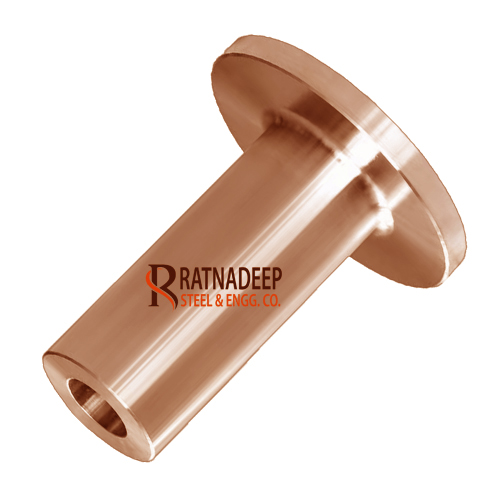

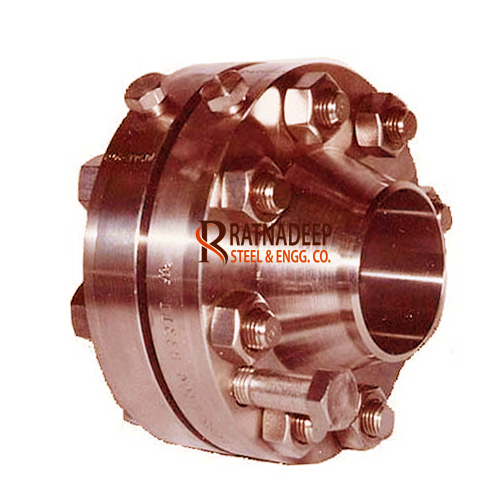

Types of Bronze Flanges

Technical Specifications

| Standard | Size Range | Pressure Rating | Face Type |

|---|---|---|---|

| ASME / ANSI B16.24 & B16.47 | ⅛” to 48” | 150# to 600# | RF, FF |

| DIN | DN15 to DN600 | PN10 to PN40 | RF, FF |

| BS / EN | Custom sizes | Class 150 – 600 | RF, FF |

Material Grades: C90300, C90700, C95400 Bronze, CuSn10, CuSn12, CuAl10Ni. Suitable for marine, chemical, and industrial applications.

Chemical & Mechanical Properties

- Tensile Strength: 380–480 MPa

- Yield Strength: 200–350 MPa

- Hardness: 90–160 HB

- Corrosion Resistance: Excellent in seawater & chemical environments

- Good wear resistance and thermal conductivity

Applications & Industries

Key Features & Benefits

- Excellent corrosion resistance in saltwater and chemicals

- Durable & long-lasting performance

- Reliable sealing under moderate pressures

- Available in various sizes and face types

- Suitable for both industrial and marine applications

Certifications & Quality Assurance

- ISO Certified

- PED Approved

- Third-party inspection (TPI) available

- Mill Test Certificates (MTC) provided

Frequently Asked Questions

Where are Bronze Flanges commonly used?

They are commonly used in marine, chemical, and industrial piping systems where corrosion resistance is critical.

What’s the difference between C90300 and C95400 Bronze?

C90300 is standard bronze suitable for most marine applications, while C95400 is nickel bronze with higher strength and corrosion resistance.

Can Bronze Flanges handle high-pressure applications?

Yes, bronze flanges are suitable for moderate to high pressures up to Class 600 / PN40 depending on material and size.

Request a Quote

Looking for reliable Bronze Flanges? Get in touch with us today.

Contact Us