What is Alloy Steel P92?

Alloy Steel P92 is a further development of P91, with the addition of tungsten (W) and a slight reduction in molybdenum. This chemical modification provides even higher creep rupture strength, allowing for design stresses approximately 25-30% higher than P91 at temperatures around 600°C. P92 enables the construction of next-generation, highly efficient ultra-supercritical power plants with reduced component wall thickness and lower weight, contributing to lower thermal stresses and improved operational flexibility.

Alloy Steel P92

Chromium (Cr)

Molybdenum (Mo)

Tungsten (W)

Vanadium (V)

Niobium (Nb)

Carbon (C)

Manganese (Mn)

Boron (B)

Iron (Fe)

Types of Alloy Steel P92 Pipes & Tubes

We are at the forefront of advanced alloy manufacturing, producing P92 pipes and tubes that meet the stringent demands of the most efficient power generation systems in the world.

P92 seamless pipes represent the pinnacle of high-temperature pipe technology. They are exclusively used in the most critical sections of advanced ultra-supercritical (USC) power plants, such as main steam and hot reheat lines, where temperatures and pressures exceed the capabilities of P91. The seamless manufacturing process is mandatory to handle the extreme service conditions, providing the highest possible assurance of safety and long-term performance under immense stress.

The use of welded P92 pipes is extremely limited and highly specialized due to the critical nature of its applications and the challenges associated with welding this advanced steel. Any welded P92 component would be subject to the most rigorous welding procedure qualifications, extensive non-destructive testing, and precisely controlled PWHT. They might be considered for non-pressure structural supports or custom fabrications within a P92 system, but seamless products are overwhelmingly preferred for pressure-containing applications.

P92 ALLOY STEEL PIPES EQUIVALENT GRADES

| STANDARD | Werkstoff /DIN | Other | Equivalent |

|---|---|---|---|

| A335 Grade P92 | 1.4901 | K92460 | X10CrWMoVNb9-2 |

Specification of Alloy Steel P92 Seamless / Welded Pipes & Tubes

| Specification | Details |

|---|---|

| Specification | ASTM A335 / ASME SA335 |

| Dimensions | ASTM, ASME and API |

| Outside Diameter | 6-2500mm; WT:1-200mm |

| Wall thickness | 0.3mm – 50 mm |

| Size | 1/8″NB TO 30″NB IN |

| Type | Seamless / ERW / Welded / Fabricated Pipes |

| Form | Round, Square, Rectangular, Oval, Hydraulic Etc |

| Length | Single Random, Double Random & Required Length |

| End | Plain End, Beveled End, Treaded |

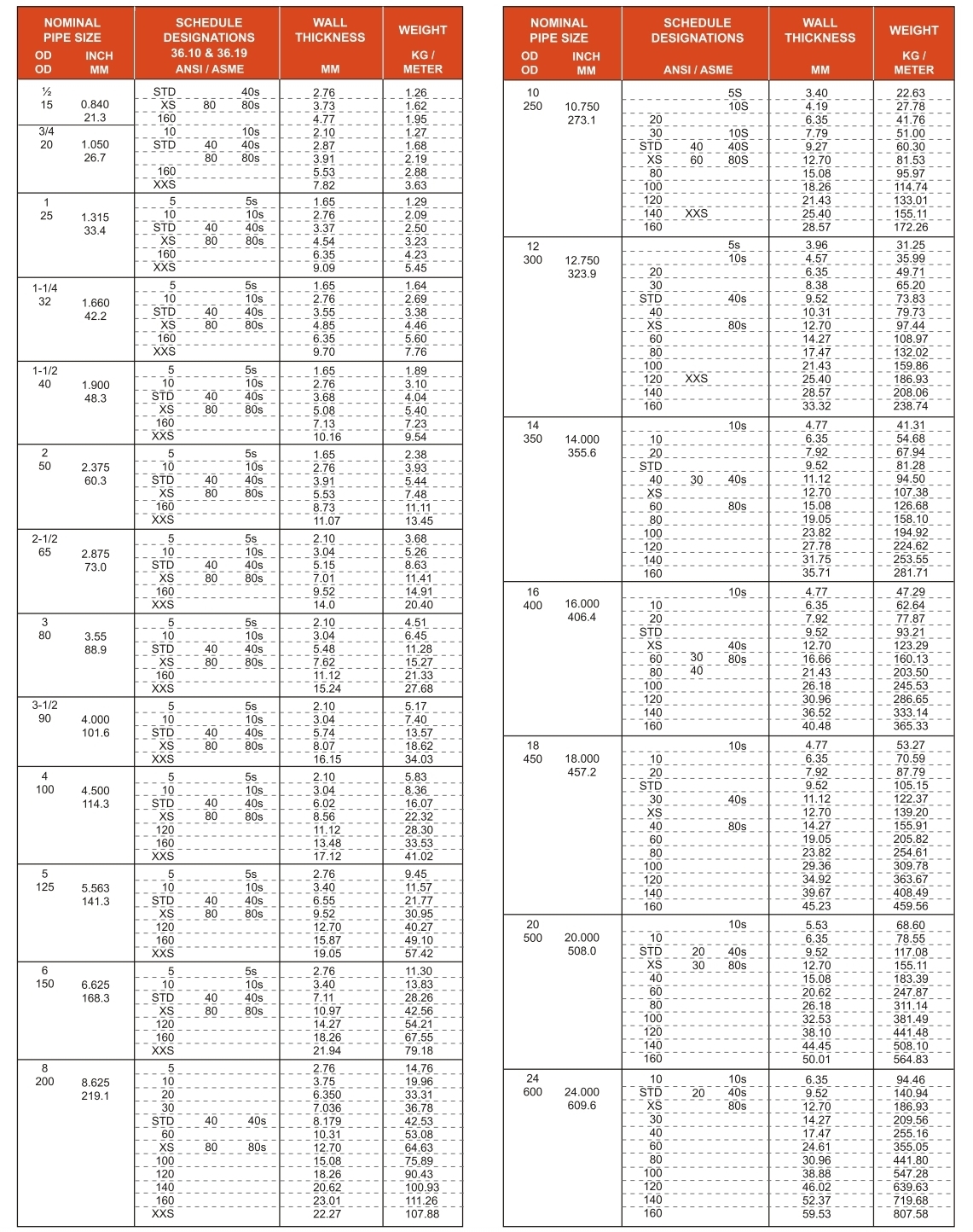

| Schedules | SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules |

| Inspection, Test Reports | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be manufactured on request |

ALLOY STEEL PIPE & TUBES SCHEDULE DIMENSIONS WALL THICKNESS, WT./MTR. (KG)

Click to expand ▼

CHEMICAL COMPOSITION OF ALLOY STEEL P92 SEAMLESS PIPES AND TUBES

| Grade | C, % | Mn, % | P, % | S, % | Si, % | Cr, % | Mo, % | V, % | N, % | Ni, % | Al, % | Nb, % | W, % |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P92 | 0.07-0.13 | 0.3-0.6 | 0.02 max | 0.01 max | 0.5 max | 8.5-9.5 | 0.3-0.6 | 0.15-0.25 | 0.03-0.07 | 0.4 max | 0.04-0.09 | 1.5-2.0 | 0.001-0.006 |

MECHANICAL PROPERTIES OF ASME SA335 ALLOY STEEL P92 PIPE

| Grade | Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

|---|---|---|---|

| P92 | 620 min | 440 min | 20 min |

💡 Practical Difference in Use

Use P92 when: you are pushing the limits of ferritic steels, requiring the highest possible creep strength for temperatures up to ~650°C (1202°F) for maximum thermal efficiency.

→ Example: The hottest sections of main steam and reheat lines, superheater tubes, and headers in the most advanced ultra-supercritical (USC) power plants.

Use P92 over P91 when: the design requires a marginal but critical increase in temperature and pressure capability, allowing for even thinner walls or higher efficiency. → Example: Next-generation power plants aiming for steam temperatures above 600°C.

Uses of Alloy Steel P92 Pipes

P92 (9Cr-0.5Mo-1.8W-V-Nb) is an advanced version of P91, with tungsten addition for enhanced solid solution strengthening, giving it the highest creep strength among commercial 9-12% Cr steels.

- Advanced USC Power Plants: Used for the highest temperature and pressure sections of steam piping and headers.

- High-Efficiency Boiler Components: Applied in superheater and reheater tubes where metal temperatures are at the upper limit for ferritic steels.

- Process Industry: For specialized high-temperature, high-pressure applications where its exceptional strength provides a design advantage.

When to Choose P92 vs. Other Alloy Steels?

P92 represents the pinnacle of high-strength ferritic/martensitic steels for power generation.

Choose P92 when:

- Designing for the highest possible efficiency with steam temperatures approaching 620°C – 650°C (1150°F – 1200°F)

- You need the absolute highest creep rupture strength available in a 9% Cr steel to minimize wall thickness

- The application is at the very upper end of P91’s capability and a stronger material is needed

Consider Austenitic/Nickel Alloys when:

- Service temperatures exceed 650°C (1202°F) continuously, where even P92’s strength declines rapidly

- Oxidation resistance becomes the limiting factor, requiring higher chromium content (e.g., 310S, 347H, Inconel/alloy 625)

Request a Quote

Looking for premium Alloy Steel P92 Pipes & Tubes? Contact us today to get the best prices.

Contact Us