What is Alloy Steel P91?

Alloy Steel P91 is a high-strength chromium-molybdenum alloy steel with vanadium and niobium (columbium) additions. It represents a significant advancement over traditional low-alloy steels, offering dramatically improved creep strength and oxidation resistance at temperatures up to about 600°C (1112°F). This allows for the design of thinner-walled, lighter-weight components that can operate at higher pressures and temperatures, leading to greater power plant efficiency. It is a normalized and tempered martensitic steel.

Alloy Steel P91

Chromium (Cr)

Molybdenum (Mo)

Vanadium (V)

Niobium (Nb)

Carbon (C)

Manganese (Mn)

Silicon (Si)

Nitrogen (N)

Iron (Fe)

Types of Alloy Steel P91 Pipes & Tubes

As specialists in high-performance alloys, we manufacture P91 pipes and tubes in both seamless and welded forms, adhering to strict heat treatment protocols to achieve the required high-strength martensitic microstructure.

P91 seamless pipes are essential for ultra-supercritical power plants and other advanced thermal systems. They are used for main steam lines, hot reheat lines, and headers where the combination of extreme pressure and temperature demands the superior creep strength of P91. The seamless construction is critical to handle the immense stresses without the risk of failure at a longitudinal weld seam, ensuring unparalleled safety and performance.

While less common than seamless due to the critical nature of its applications, P91 welded pipes are produced for specific large-diameter or custom-sized components. Their manufacture requires extreme precision in welding and a strict post-weld heat treatment (PWHT) cycle to develop the correct tempered martensite structure and achieve the necessary mechanical properties. They are used in applications like certain large-headers or structural supports within high-temperature plants.

P91 ALLOY STEEL PIPES EQUIVALENT GRADES

| STANDARD | Werkstoff /DIN | Other | Equivalent |

|---|---|---|---|

| A335 Grade P91 | 1.4903 | k91560 | X10CrMoVNb9-1 |

Specification of Alloy Steel P91 Seamless / Welded Pipes & Tubes

| Specification | Details |

|---|---|

| Specification | ASTM A335 / ASME SA335 |

| Dimensions | ASTM, ASME and API |

| Outside Diameter | 6-2500mm; WT:1-200mm |

| Wall thickness | 0.3mm – 50 mm |

| Size | 1/8″NB TO 30″NB IN |

| Type | Seamless / ERW / Welded / Fabricated Pipes |

| Form | Round, Square, Rectangular, Oval, Hydraulic Etc |

| Length | Single Random, Double Random & Required Length |

| End | Plain End, Beveled End, Treaded |

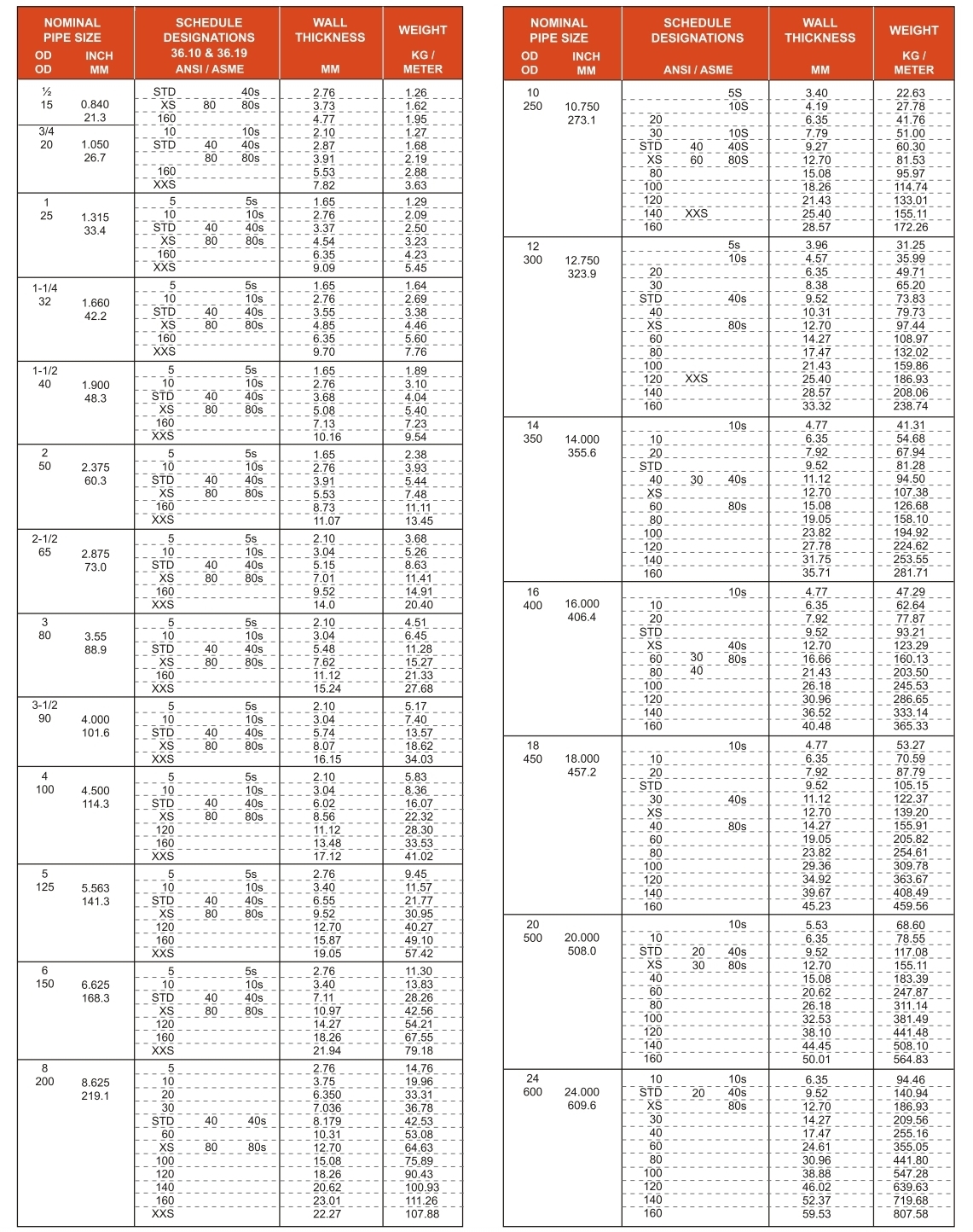

| Schedules | SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules |

| Inspection, Test Reports | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be manufactured on request |

ALLOY STEEL PIPE & TUBES SCHEDULE DIMENSIONS WALL THICKNESS, WT./MTR. (KG)

Click to expand ▼

CHEMICAL COMPOSITION OF ALLOY STEEL P91 SEAMLESS PIPES AND TUBES

| Grade | C, % | Mn, % | P, % | S, % | Si, % | Cr, % | Mo, % |

|---|---|---|---|---|---|---|---|

| P91 | 0.08~0.12 | 0.30~0.60 | 0.02 | 0.01 | 0.20~0.50 | 8.00~9.50 | 0.85~1.05 |

MECHANICAL PROPERTIES OF ASME SA335 ALLOY STEEL P91 PIPE

| Grade | Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

|---|---|---|---|

| P91 | 585 min | 415 min | 20 min |

💡 Practical Difference in Use

Use P91 when: you require high creep strength and excellent oxidation resistance for high-pressure, high-temperature service up to about 625°C (1157°F).

→ Example: Main steam and hot reheat lines, headers, and high-temperature superheater tubes in modern power plants.

Use P91 over other grades when: you are designing for higher thermal efficiency, which requires components to withstand higher steam pressures and temperatures with thinner walls compared to traditional steels like P22. → Example: Advanced ultra-supercritical (USC) power plant components.

Uses of Alloy Steel P91 Pipes

P91 (9Cr-1Mo-V) is a high-strength, advanced ferritic steel that revolutionized the design of high-temperature power plant components.

- High-Pressure Steam Piping: The dominant use is for main steam and hot reheat piping systems in supercritical and ultra-supercritical power plants.

- Boiler Headers: Used for superheater and reheater headers where its high strength allows for larger diameters with thinner walls.

- Heat Exchanger Tubing: Employed in high-temperature heat exchangers in process industries where its strength and corrosion resistance are beneficial.

When to Choose P91 vs. Other Alloy Steels?

P91 is a significant step up from traditional Cr-Mo steels due to its precipitation strengthening from vanadium and niobium.

Choose P91 when:

- Metal temperatures are in the range of 580°C to 625°C (1076°F – 1157°F)

- The goal is to reduce component weight and thermal stress through the use of thinner walls

- You need the high-temperature strength of a 9% chromium steel without the cost of an austenitic stainless steel

Consider P92 or Austenitic Steels when:

- Service temperatures exceed 625°C (1157°F), where P92 offers even higher strength

- The environment is too oxidizing for 9-12% chromium steels, necessitating a stainless grade like 304H or 310H

Request a Quote

Looking for premium Alloy Steel P91 Pipes & Tubes? Contact us today to get the best prices.

Contact Us