What is Alloy Steel P22?

Alloy Steel P22, also known as 2.25Cr-1Mo, is one of the most common and versatile chromium-molybdenum steels for high-temperature service. It offers superior creep strength, oxidation resistance, and toughness compared to the lower chromium grades (P11, P12). P22 is a cornerstone material for high-pressure piping, headers, and pressure vessels in fossil fuel power plants and petrochemical industries, capable of withstanding demanding thermal and pressure cycles.

Alloy Steel P22

Chromium (Cr)

Molybdenum (Mo)

Carbon (C)

Manganese (Mn)

Silicon (Si)

Phosphorus (P) Max

Sulfur (S) Max

Iron (Fe)

Types of Alloy Steel P22 Pipes & Tubes

We are a leading producer of Alloy Steel P22 pipes and tubes, offering both seamless and welded options to meet the high standards of the power and hydrocarbon processing sectors.

P22 seamless pipes are the industry standard for critical high-temperature, high-pressure applications. They are predominantly used for main steam and hot reheat lines in power stations, as well as for high-pressure headers and boiler components. The seamless manufacturing process guarantees excellent internal soundness and superior resistance to creep deformation, ensuring long-term structural integrity under the most strenuous operating conditions.

P22 welded pipes provide a viable and economical alternative for applications that do not demand the highest pressure ratings but still require the material’s excellent high-temperature properties. They are often employed in large-diameter pipework for power plant auxiliary systems, refinery heater coils, and other process piping. Rigorous non-destructive testing and heat treatment are applied to ensure the weld area achieves properties consistent with the base metal.

P22 ALLOY STEEL PIPES EQUIVALENT GRADES

| STANDARD | Werkstoff /DIN | Other | Equivalent |

|---|---|---|---|

| A335 Grade P22 | 1.7380 | K21590 | 10CrMo9-10 |

Specification of Alloy Steel P22 Seamless / Welded Pipes & Tubes

| Specification | Details |

|---|---|

| Specification | ASTM A335 / ASME SA335 |

| Dimensions | ASTM, ASME and API |

| Outside Diameter | 6-2500mm; WT:1-200mm |

| Wall thickness | 0.3mm – 50 mm |

| Size | 1/8″NB TO 30″NB IN |

| Type | Seamless / ERW / Welded / Fabricated Pipes |

| Form | Round, Square, Rectangular, Oval, Hydraulic Etc |

| Length | Single Random, Double Random & Required Length |

| End | Plain End, Beveled End, Treaded |

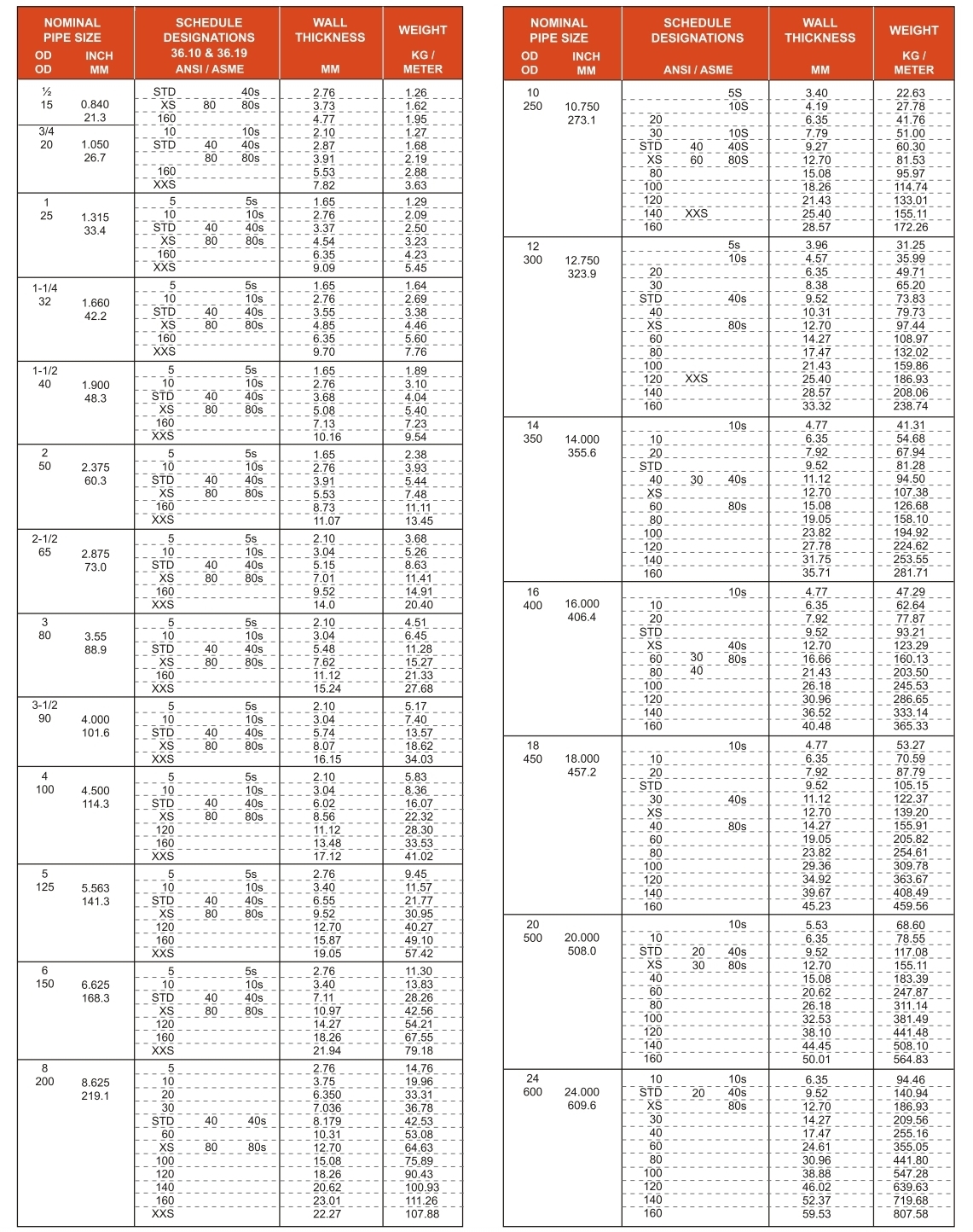

| Schedules | SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules |

| Inspection, Test Reports | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be manufactured on request |

ALLOY STEEL PIPE & TUBES SCHEDULE DIMENSIONS WALL THICKNESS, WT./MTR. (KG)

Click to expand ▼

CHEMICAL COMPOSITION OF ALLOY STEEL P22 SEAMLESS PIPES AND TUBES

| Grade | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

|---|---|---|---|---|---|---|---|

| P22 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 1.90~2.60 | 0.87~1.13 |

MECHANICAL PROPERTIES OF ASME SA335 ALLOY STEEL P22 PIPE

| Grade | Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

|---|---|---|---|

| P22 | 415 min | 205 min | 30 min |

💡 Practical Difference in Use

Use P22 when: you need a robust, well-understood alloy with good high-temperature strength and creep resistance up to about 580°C (1076°F).

→ Example: Boiler headers, steam pipes, superheater tubes, and pressure vessels.

Use P22 over other grades when: it represents the standard workhorse alloy for many high-temperature pressure applications, offering an excellent balance of strength, fabricability, and cost. → Example: Main steam lines and high-pressure headers in power plants.

Uses of Alloy Steel P22 Pipes

P22 (2.25Cr-1Mo) is one of the most widely used chromium-molybdenum steels for high-temperature service.

- Power Plant Piping and Headers: The primary use is for critical high-pressure steam lines, headers, and manifolds.

- Boiler Components: Used for superheater and reheater tubes, especially in sections with higher metal temperatures.

- Petrochemical Reactors: Commonly used in the fabrication of hydrogen reactors and other high-pressure vessels in refineries due to its excellent resistance to hydrogen embrittlement.

When to Choose P22 vs. Other Alloy Steels?

P22 is a benchmark material. The decision often revolves around whether its proven performance is sufficient or if a more advanced alloy is justified.

Choose P22 when:

- Operating temperatures are in the range of 500°C to 580°C (932°F – 1076°F)

- You need a reliable, well-documented alloy with a vast history of successful use

- Excellent resistance to hydrogen attack is required for refinery service

Consider P91 when:

- Higher temperatures and pressures demand a stronger alloy to reduce component wall thickness and weight

- Superior creep strength is needed for increased efficiency and service life

- The application is for a modern, high-efficiency power plant

Request a Quote

Looking for premium Alloy Steel P22 Pipes & Tubes? Contact us today to get the best prices.

Contact Us