Overview

Duplex and Super Duplex Steel Flanges combine the strength of ferritic steel with the corrosion resistance of austenitic steel. They are widely used in offshore, marine, chemical processing, and desalination plants, where superior performance in harsh and chloride-rich environments is required.

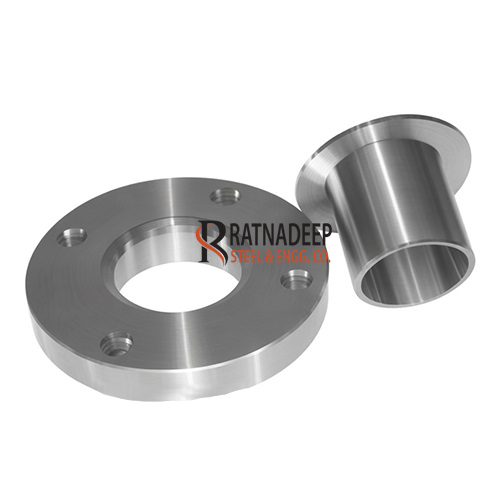

Types of Duplex Steel Flanges

Technical Specifications

| Standard | Size Range | Pressure Rating | Face Type |

|---|---|---|---|

| ASME / ANSI B16.5 & B16.47 | ⅛” to 48” | 150# to 2500# | RF, RTJ |

| DIN | DN10 to DN2000 | PN6 to PN400 | RF, FF |

| JIS | 10A to 1500A | 5K to 30K | FF, RF |

Material Grades: Duplex 2205, Super Duplex 2507

UNS: S31803, S32750, S32760, S32900

Chemical & Mechanical Properties

- Tensile Strength: 620 MPa min

- Yield Strength: 450 MPa min

- Hardness: 250 HB max

- Excellent pitting & crevice corrosion resistance

- Balanced ferrite-austenite microstructure

Applications & Industries

Key Features & Benefits

- High resistance to chloride stress corrosion cracking

- Superior strength compared to standard stainless steel

- Excellent performance in seawater & harsh chemicals

- Leak-proof, durable & long service life

- Available in Duplex (2205) & Super Duplex (2507)

Certifications & Quality Assurance

- ISO Certified

- PED & IBR Approved

- Third-party inspection (TPI) available

- Mill Test Certificates (MTC) provided

Frequently Asked Questions

What is the difference between Duplex and Super Duplex flanges?

Super Duplex (2507) offers higher strength and better corrosion resistance than Duplex (2205), especially in seawater and aggressive environments.

Are Duplex Steel Flanges suitable for marine applications?

Yes, Duplex and Super Duplex flanges are ideal for marine and offshore applications due to their excellent chloride resistance.

Which UNS grades are available?

Available grades include UNS S31803, S32750, S32760, and S32900.

Request a Quote

Looking for premium Duplex & Super Duplex Steel Flanges? Get in touch with us today.

Contact Us