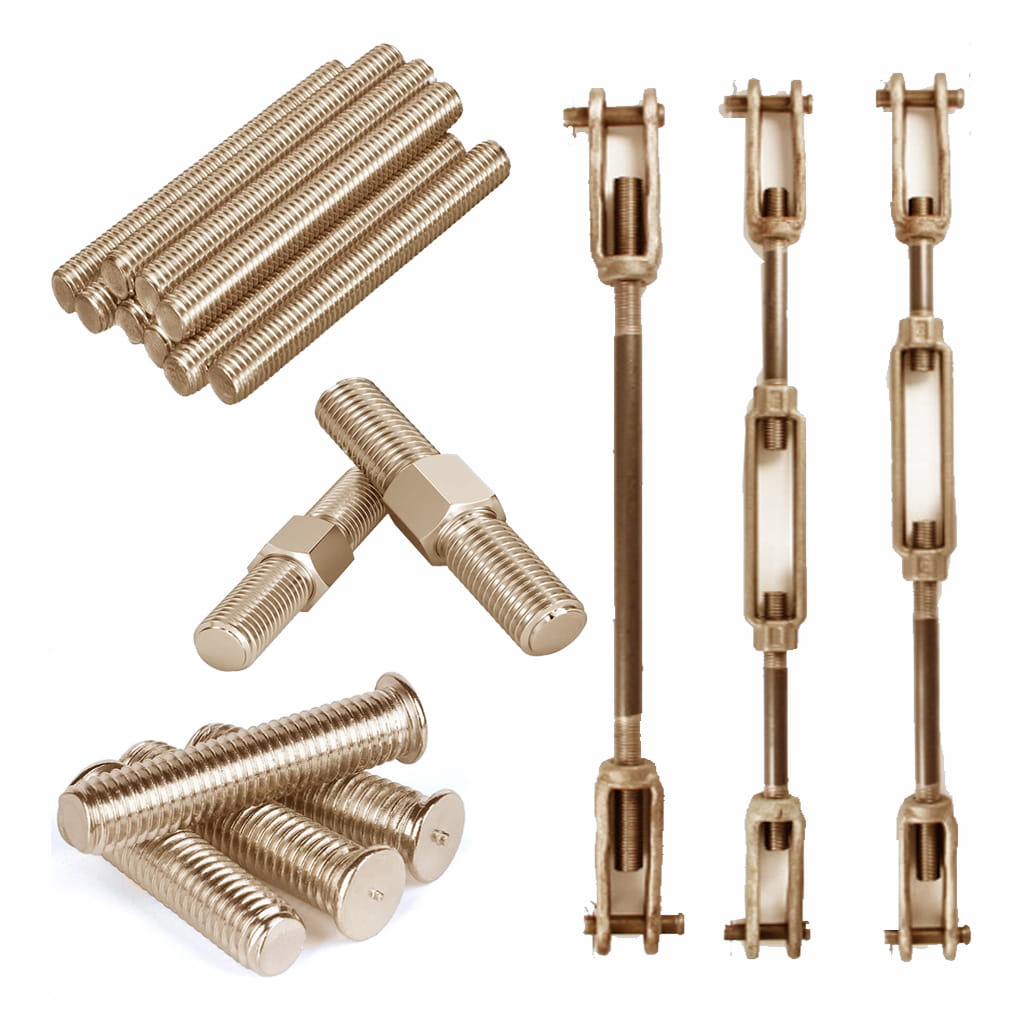

High Quality Nickel Alloy 200/201 Fasteners

Standards Compliance • Ready Stock • Support

Get a QuotePremium Nickel Alloy 200/201 Fasteners by Ratnadeep Steel & Engg. Co.

Ratnadeep Steel & Engg. Co. is a leading manufacturer, exporter, and supplier of premium-quality Nickel Alloy 200/201 Fasteners. Manufactured from high-purity nickel alloys using advanced production processes, our fasteners ensure excellent corrosion resistance, dimensional accuracy, and long-term reliability for critical applications requiring durability and performance in extreme environments.

Nickel Alloy 200 and 201 fasteners are widely preferred for their outstanding resistance to corrosion, oxidation, and chemical attack, especially in acidic and alkaline media. They offer excellent mechanical properties and thermal stability, making them suitable for high-temperature and highly corrosive service conditions. Nickel 201, with lower carbon content, provides improved resistance to intergranular corrosion.

With precise threading, smooth surface finishes, and tight tolerances, our Nickel Alloy 200/201 fasteners deliver dependable performance under vibration, heat, and chemical exposure. They are ideal for chemical processing, petrochemical plants, marine applications, power generation, food processing, and general industrial applications.

Our Range of Nickel Alloy 200 / 201 Industrial Fasteners

- Nickel Alloy 200 / 201 Hex & Heavy Hex Nuts

- UNS N02200 & UNS N02201 Lock and Nylon Insert Nuts

- DIN 2.4066 / 2.4068 Nickel Alloy Coupling Nuts

- Excellent resistance to alkalis and corrosive media

- ASTM B160 Nickel Alloy 200 & 201 Hex Bolts

- DIN 2.4066 / 2.4068 Heavy Hex & Machine Bolts

- UNS N02200 / N02201 High-Purity Nickel Bolting

- Used in chemical processing and heat transfer systems

- ASTM B160 Nickel Alloy 200 / 201 Screws

- Socket Head Cap, Button Head & Set Screws

- DIN 2.4066 / 2.4068 Precision Machined Screws

- Excellent performance in caustic environments

- Nickel Alloy 200 / 201 Plain & Spring Lock Washers

- Split, Ogee & Dock Washers as per DIN standards

- Uniform load distribution with corrosion resistance

- Ideal for chemical and marine fastener assemblies

- ASTM B160 Nickel Alloy 200 / 201 Stud Bolts

- Single Ended, Double Ended & Fully Threaded Studs

- UNS N02200 / N02201 for high-purity applications

- Used in flanges, valves & pressure equipment

- ASTM B160 Nickel Alloy 200 / 201 Threaded Rods

- Fully Threaded and Cut-to-Length Stud Rods

- DIN 2.4066 / 2.4068 Nickel Alloy Tie Rods

- High purity nickel for critical chemical services

200 / 201 NICKEL ASTM B160 FASTENERS EQUIVALENT GRADES

| Standard | Werkstoff Nr. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 2.4066 | N02200 | NW 2200 | NA 11 | НП-2 | N-100M | Ni 99.2 |

| Nickel 201 | 2.4068 | N02201 | NW 2201 | NA 12 | НП-2 | — | LC-Ni 99 |

SPECIFICATION OF NICKEL ALLOY FASTENERS

| Specification | ASTM B160 / ASME SB160 |

|---|---|

| Dimension Standards | DIN, ISO, ASTM, JIS, BS, GB, IS and all International Standards |

| Size Range | M3 – M56 | 3/6" to 2" | Custom Sizes |

| Length | 3 mm to 200 mm |

| Types | Nuts, Bolts, Screws, Sockets, Studs, Hex Set Screws, Socket Screws, Cap Screws, Pan Head Screws, Machine Screws, Socket Head Cap Screws, Allen Cap Screws, Wing Screws, Washers, Spring Washers, Anchors, Marine Anchors, Hexagon Nuts, Hex Nuts, Coupling Nuts, Hex Domed Cap Nuts, Square Nuts, Stud Bolts, Hex Head Bolts, Socket Hexagon Head Screw Anchor Bolts, U-Bolts, J-Bolts, Mushroom Head Square Neck Bolts, T-Head Bolts, Eye Bolts, Foundation Bolts, Structural Bolts |

CHEMICAL COMPOSITION OF NICKEL 200 / 201 INDUSTRIAL FASTENERS

| Element | Nickel Alloy 200 | Nickel Alloy 201 |

|---|---|---|

| Ni | 99.00 | 99.00 |

| Fe | 0.40 | 0.40 |

| Mn | 0.35 | 0.35 |

| Si | 0.35 | 0.35 |

| C | 0.15 | 0.02 |

| S | 0.01 | 0.01 |

| Cu | 0.25 | 0.25 |

MECHANICAL PROPERTIES OF ASME SB160 NICKEL FASTENERS

| Nickel Alloy 200 | ||

|---|---|---|

| Properties | Metric | Imperial |

| Tensile Strength (Annealed) | 462 MPa | 67,000 psi |

| Yield Strength (Annealed) | 148 MPa | 21,500 psi |

| Elongation at Break (Annealed) | 45% | 45% |

| Nickel Alloy 201 | ||

| Properties | Metric | Imperial |

| Tensile Strength (Annealed) | 403 MPa | 58,500 psi |

| Yield Strength (Annealed) | 103 MPa | 14,900 psi |

| Elongation at Break (Annealed) | 50% | 50% |

PHYSICAL PROPERTIES OF NICKEL 200 / 201 FASTENERS

| Density | 8.902 g/cm³ |

|---|---|

| Melting Point | 1453 °C |

| Boiling Point | 2732 °C |

| Thermal Conductivity | 0.909 W/cm/K @ 298.2 K |

| Electrical Resistivity | 6.84 μΩ·cm @ 20 °C |

| Electronegativity | 1.8 Pauling |

| Specific Heat | 0.106 Cal/g·K @ 25 °C |

| Heat of Vaporization | 91.0 K-Cal/g atom @ 2732 °C |

| Heat of Fusion | 4.20 Cal/g mole |

💡 Practical Difference in Use

Use Nickel Alloy 200/201 Fasteners when: exceptional corrosion resistance, high purity, and reliable performance in chemical or high-temperature environments are required in critical industrial applications. → Example: chemical processing equipment, food processing plants, marine components, heat exchangers, and caustic handling systems.

Applications of Nickel Alloy 200/201 Fasteners

Nickel Alloy 200/201 fasteners are known for their outstanding resistance to corrosion, oxidation, and chemical attack. These high-performance nickel alloy fasteners are ideal for harsh environments involving acids, alkalis, and high temperatures where long service life and material stability are essential.

- Chemical Processing: Reactors, pressure vessels, and handling equipment for corrosive chemicals.

- Food & Pharmaceutical: Processing equipment requiring high purity and contamination resistance.

- Marine & Offshore: Components exposed to saltwater and humid environments.

When to Choose Nickel Alloy 200/201 Fasteners?

Nickel Alloy 200/201 fasteners are selected for applications requiring superior corrosion resistance, thermal stability, and reliable performance in aggressive chemical environments.

Choose Nickel Alloy 200/201 Fasteners when:

- Excellent resistance to acids, alkalis, and chemicals is required

- High-temperature oxidation resistance is needed

- Low-carbon Nickel 201 is preferred to resist intergranular corrosion

- High purity material is required for sensitive processes

- Long service life in corrosive environments is critical

Industries That Use Nickel Alloy 200/201 Fasteners

Nickel Alloy 200/201 fasteners are widely used in industries that demand high corrosion resistance, purity, and performance in extreme environments.

Ideal for highly corrosive chemical environments.

Uses

Chemical reactors, transfer systems, and storage vessels.

Why Nickel Alloy 200/201 Fasteners?

Exceptional resistance to chemical corrosion.

Used in high-purity processing systems.

Uses

Food handling equipment and pharmaceutical machinery.

Why Nickel Alloy 200/201 Fasteners?

High purity and contamination resistance.

Suitable for harsh marine conditions.

Uses

Offshore platforms, coastal equipment, and seawater systems.

Why Nickel Alloy 200/201 Fasteners?

Excellent resistance to moisture and salt corrosion.

Reliable in high-temperature applications.

Uses

Heat exchangers, turbines, and thermal systems.

Why Nickel Alloy 200/201 Fasteners?

Thermal stability and oxidation resistance.

Usage Guide for Nickel Alloy 200/201 Fasteners

Nickel Alloy 200/201 nuts provide secure, corrosion-resistant mating with bolts in chemical and high-temperature environments.

Choose Nickel Alloy 200/201 Nuts when

- Excellent corrosion resistance to chemicals and alkalis is required

- Used in chemical processing or marine environments

- High-purity, contamination-free fastening is needed

- Long service life in corrosive conditions is critical

Nickel 200/201 bolts offer durable fastening in corrosive and elevated-temperature applications.

Choose Nickel Alloy 200/201 Bolts when

- Resistance to acids, alkalis, or saltwater is essential

- Used in chemical, petrochemical, or marine industries

- High thermal and oxidation resistance is needed

- Reliable performance in harsh environments is required

Nickel alloy screws ensure secure fastening where corrosion and heat resistance are priorities.

Choose Nickel Alloy 200/201 Screws when

- Fastening in corrosive or humid environments is required

- Used in food, pharmaceutical, or clean-process industries

- Non-magnetic and high-purity material is preferred

- Long-term corrosion resistance is important

Nickel Alloy 200/201 washers improve load distribution while resisting chemical attack.

Choose Nickel Alloy 200/201 Washers when

- Corrosion-resistant load distribution is necessary

- Joint protection in chemical environments is required

- Exposure to moisture or chemicals is expected

- Used in critical corrosion-resistant assemblies

Nickel Alloy 200/201 stud bolts are ideal for corrosion-resistant flange connections.

Choose Nickel Alloy 200/201 Stud Bolts when

- Used in chemical plants or caustic handling systems

- Flange connections face corrosive media

- Low-carbon Nickel 201 is needed to prevent intergranular corrosion

- Reliable sealing under chemical exposure is required

Nickel Alloy 200/201 threaded rods provide flexible, corrosion-resistant fastening.

Choose Nickel Alloy 200/201 Threaded Rods when

- Custom-length corrosion-resistant fastening is needed

- Used in chemical equipment or marine installations

- High resistance to alkalis and chemicals is required

- Long-term durability in harsh environments is critical

Our Industrial Fasteners are manufactured using precision forging and machining processes to ensure excellent dimensional accuracy, strength, and long-term performance. Each fastener undergoes strict quality inspections, including visual and dimensional checks, tensile testing, hardness testing, and thread gauging to verify compliance with specified tolerances.

Comprehensive chemical composition analysis and mechanical property testing are carried out to confirm material integrity and standard conformity. Where required, additional NDT methods such as ultrasonic testing, magnetic particle inspection (MPI), or dye penetrant testing (DPT) are performed to detect surface or internal defects. Controlled forging, heat treatment, and threading processes eliminate issues such as cracks, laps, and thread imperfections.

All fasteners are manufactured and tested in accordance with international standards including ASTM, ASME, ISO, DIN, BS, and IS specifications. Engineered for reliable performance in high-pressure, high-temperature, and corrosive environments, our fasteners are widely used across oil & gas, petrochemical, power generation, construction, and heavy engineering industries.

Request a Quote

Looking for high-quality Nickel Alloy 200/201 Fasteners? Get in touch with us today.

Contact Us