Premium Copper Nickel 90/10 Forged Pipe Fittings by Ratnadeep Steel & Engg. Co.

Ratnadeep Steel & Engg. Co. is a reputed manufacturer, exporter, and supplier of Copper Nickel 90/10 Forged Pipe Fittings, offering excellent corrosion resistance and cost-effective performance in seawater and brackish water piping systems. Copper Nickel 90/10, containing 90% copper and 10% nickel, provides outstanding resistance to biofouling and stress corrosion.

Copper Nickel 90/10 Forged Pipe Fittings deliver reliable mechanical strength, good ductility, and ease of fabrication. These forged fittings perform efficiently under moderate temperatures and pressures while maintaining excellent weldability and long service life. Accurately machined threads and socket weld ends ensure secure connections, smooth flow, and superior joint integrity.

Commonly used in seawater piping, condenser units, shipbuilding, offshore structures, fire water systems, and heat exchangers, our Copper Nickel 90/10 forged fittings meet stringent international standards. Choose Ratnadeep Steel & Engg. Co. for high-quality copper nickel forged fittings that ensure durability, efficiency, and corrosion resistance.

- Cupro Nickel 90/10 Socket Weld Elbow

- UNS C70600 Threaded Elbow

- DIN 2.0872 Forged Elbow

- ASME SB467 Cupro Nickel 90/10 45° Threaded Elbow

- Cupro Nickel 90/10 90° Forged Elbow

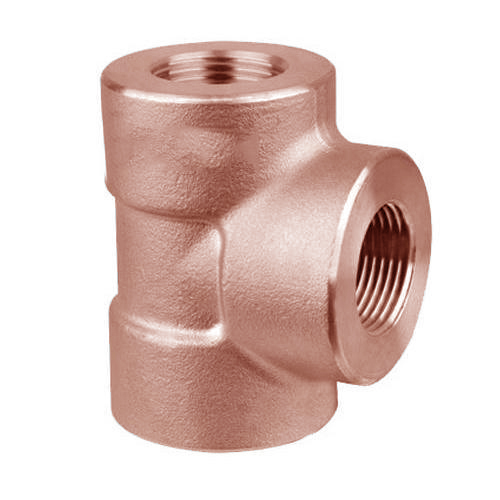

- ASME SB467 Copper Nickel 90/10 Socket Weld Tee

- ASTM B467 Cupro Nickel 90/10 Forged Equal Tee

- DIN 2.0872 Reducing Tee

- UNS C70600 Unequal Tee

- Cu-Ni Alloy 90/10 Threaded Equal Tee

- Cupro Nickel Alloy 90/10 Threaded Equal Cross

- UNS C70600 / DIN 2.0872 Forged Cross

- Cu-Ni Alloy 90/10 Socketweld Equal Cross

- Cupro Nickel 90/10 Threaded Cross

- Copper Nickel Alloy 90/10 Reducing Cross

- DIN 2.0872 Threaded Full Coupling

- UNS C70600 Forged Full Coupling

- ASME SB467 Copper Nickel 90/10 Socketweld Full Coupling

- ASTM B467 Cupro Nickel Alloy 90/10 Full Coupling

- ASTM B467 90/10 Cupro Nickel Socket Weld Half Coupling

- Alloy UNS C70600 Forged Half Coupling

- ANSI B16.11 Cupro Nickel 90/10 Threaded Half Coupling

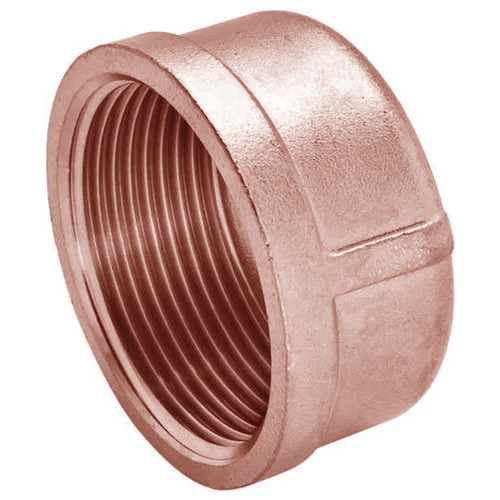

- UNS C70600 Forged Pipe End Cap

- Cupro Nickel 90/10 Threaded Pipe Cap

- ASTM B467 Cupro Nickel 90/10 Socketweld Pipe Cap

- ASME SB467 Copper Nickel Alloy 90/10 Forged Pipe End Cap

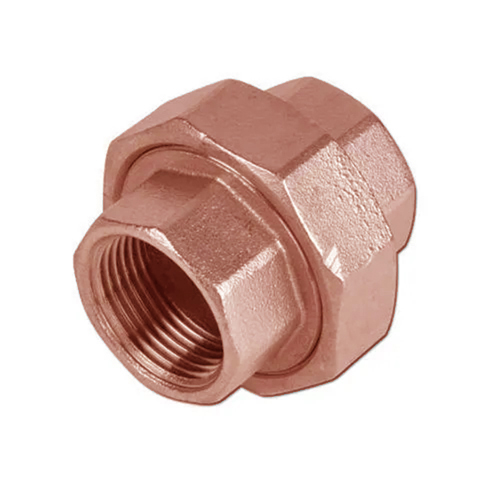

- UNS C70600 Socketweld Union

- ANSI B16.5 Cupro Nickel 90/10 Union

- ASTM B467 Cu-Ni Alloy 90/10 Threaded Union

- ASME SB467 Cupro Nickel 90/10 Forged Union

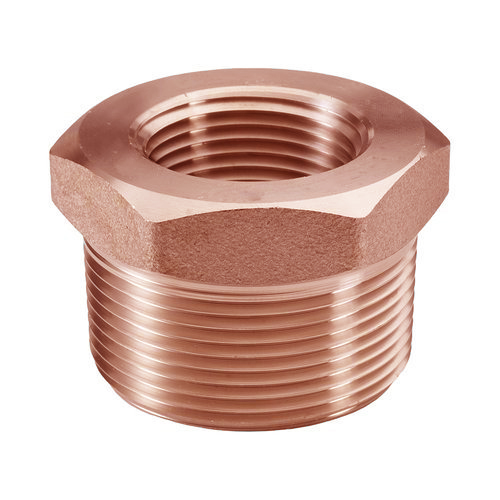

- UNS C70600 Forged Bushing

- B16.36 Cupro Nickel 90/10 Hex Head Bushing

- ASTM B467 Cupro Nickel 90/10 Threaded Bushing

- ASME SB467 Cupro Nickel 90/10 Forged Threaded Bushing

- UNS C70600 Threaded Nipple

- B16.36 Cupro Nickel Alloy 90/10 Socketweld Nipple

- ASTM B467 Copper Nickel 90/10 Swage Nipple

- ASME SB467 Cupro Nickel Alloy 90/10 Hex Nipple

- Copper Nickel 90/10 Screwed Pipe Nipple

CHEMICAL COMPOSITION OF COPPER NICKEL 90/10 FORGED PIPE FITTINGS

| Element | Cu | Ni | Fe | Mn | Zn | Pb | Other |

|---|---|---|---|---|---|---|---|

| Copper Nickel 90/10 | 88.6 min | 9-11 | 1.0-1.8 | 1.0 max | 1.0 max | 0.05 max | 0.5 max |

MECHANICAL PROPERTIES OF ASME SB122 COPPER NICKEL 90/10 FORGED PIPE FITTINGS

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength, Ultimate | 303-414 MPa | 43900-60000 psi |

| Tensile Strength, Yield | 110-393 MPa | 16000-57000 psi |

| Elongation at Break (in 254 mm) | 42.00% | 42.00% |

| Machinability (UNS C36000 = 100%) | 20% | 20% |

| Shear Modulus | 52.0 GPa | 7540 ksi |

| Poisson’s Ratio | 0.34 | 0.34 |

| Elastic Modulus | 140 GPa | 20300 ksi |

SPECIFICATION OF NICKEL 90/10 FORGED FITTINGS

| Specification | ASTM B467 / ASME SB467 |

|---|---|

| Dimension Standard | ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799 |

| Size | 1/8″ NB to 4″ NB |

| Type | Socketweld Fittings, Screwed-Threaded Fittings (NPT or PT Type) |

| Rating Pressure | Threaded End – 2000 / 3000/ 6000 LBS. Socket-weld End – 3000 / 6000/ 9000 LBS. |

COPPER NICKEL 90/10 ASTM B122 FORGED FITTINGS EQUIVALENT GRADES

| STANDARD | UNS | WNR. | EN | DIN | JIS | BS |

|---|---|---|---|---|---|---|

| Copper Nickel 90/10 | C70600 | 2.0872 | CuNi10Fe1Mn | CuNi10Fe | C7060 | CN 102 |

PHYSICAL PROPERTIES OF ASTM B171 CU-NI 90/10 PIPE FITTINGS

| Property | Metric | Imperial |

|---|---|---|

| Density | 8.94 g/cm³ | 0.323 lb/in³ |

| Melting Point | 1100°C | 2012°F |

| Specific Heat @ 20°C (68°F) | 0.377 J/g·°C | 0.090 Btu/lb·°F |

| Thermal Conductivity @ 20°C (68°F) | 40 W/m·K | 277 Btu·in/h·ft²·°F |

| Electrical Resistivity @ 20°C (68°F) | 0.027 μΩ·m | 0.027 μΩ·m |

| Mean Coefficient of Thermal Expansion (20-100°C) | 17.1 × 10⁻⁶ /°C | 9.5 × 10⁻⁶ /°F |

| Magnetic Permeability | Non-magnetic | Non-magnetic |

💡 Practical Difference in Use

Use Copper Nickel 90/10 Forged Pipe Fittings when: cost-effective corrosion resistance is required in moderate seawater and brackish water systems with compact, leak-proof joints. This alloy offers excellent resistance to biofouling and stress corrosion. → Example: seawater piping, fire water systems, shipbuilding, and condenser lines.

Applications of Copper Nickel 90/10 Forged Pipe Fittings

Cu-Ni 90/10 forged fittings provide reliable service in marine and industrial water applications.

- Seawater Systems: Cooling water and fire protection pipelines.

- Shipbuilding: Compact onboard piping systems.

- Heat Exchangers: Condenser and cooling circuits.

When to Choose Copper Nickel 90/10?

This grade is suitable for moderate marine exposure with economical performance.

Choose Copper Nickel 90/10 Forged Fittings when:

- Moderate seawater exposure exists

- Resistance to biofouling is important

- Cost efficiency is required

- Threaded or socket weld joints are preferred

- Used in marine or utility water systems

Usage Guide for Copper Nickel 90/10 Forged Pipe Fittings

Directional change in compact forged piping systems.

Choose Socket Weld Elbow when

- 90° direction change is required

- Leak-resistant welded joints

- Used in marine and cooling systems

- Moderate pressure service

Threaded branch distribution in utility marine piping.

Choose Forged Tee when

- Flow distribution is required

- Marine fire water systems

- Cost-effective branching

- Moderate pressure lines

Four-way threaded distribution in marine service lines.

Choose Cross when

- Multi-directional flow is required

- Utility marine piping

- Moderate pressure systems

- Cost-effective forged construction

Connects two pipes securely in seawater service.

Choose Full Coupling when

- Pipe-to-pipe connection is required

- Cooling water and marine lines

- Leak-resistant threaded joints

- Moderate pressure operation

Branch outlet connection for instrumentation and drains.

Choose Half Coupling when

- Instrument tapping is required

- Moderate pressure service

- Marine and cooling systems

- Compact forged design

Seals threaded pipe ends in marine and industrial water systems.

Choose Cap when

- Pipe termination is required

- Temporary or permanent sealing

- Moderate corrosion resistance

- Marine utility piping

Allows easy dismantling in seawater and cooling lines.

Choose Union when

- Frequent maintenance is required

- Marine and shipbuilding applications

- Leak-tight threaded joints

- Cooling water systems

Threaded size reduction in compact marine piping.

Choose Bushing when

- Pipe size reduction is required

- Space-saving installation

- Used in utility seawater lines

- Cost-efficient solution

Short threaded extension for marine and seawater utility systems.

Choose Nipple when

- Compact threaded connection is required

- Moderate seawater exposure exists

- Marine utility piping

- Good corrosion resistance is needed

Our Forged Pipe Fittings are manufactured using advanced forging processes and undergo extensive quality checks to ensure flawless dimensional accuracy, durability, and long service life. Each fitting is thoroughly inspected using key NDT techniques such as radiographic testing (RT), ultrasonic testing (UT), hydrostatic testing, and visual/dimensional examination. We also perform detailed chemical composition analysis and mechanical property testing to ensure material compliance with strict industry standards.

Throughout the forging and finishing stages, every forged fitting is monitored closely to eliminate defects such as misalignment, surface irregularities, and wall-thickness variations. This ensures perfect joint integrity and high-performance reliability in pipelines carrying high temperatures, pressures, and corrosive media. All our forged fittings fully comply with ASME, ASTM, MSS-SP, and related global specifications, making them a preferred choice for critical piping systems worldwide.

Request a Quote

Looking for high-quality Copper Nickel 90/10 Forged Pipe Fittings Manufacturer and Exporter in India Buttweld Pipe Fittings? Get in touch with us today.

Contact Us