What is Alloy Steel P12?

Alloy Steel P12 is another fundamental chromium-molybdenum alloy steel, similar to P11 but with a slightly lower chromium content. It is a versatile and economical grade known for its good weldability and improved strength over carbon steel at elevated temperatures. P12 is commonly used in power plants for steam piping, headers, and boiler tubes, as well as in refineries for process piping.

Alloy Steel P12

Chromium (Cr)

Molybdenum (Mo)

Carbon (C)

Manganese (Mn)

Silicon (Si)

Phosphorus (P) Max

Sulfur (S) Max

Iron (Fe)

Types of Alloy Steel P12 Pipes & Tubes

Our manufacturing capabilities for Alloy Steel P12 include both seamless and welded pipes & tubes, catering to a wide array of industrial applications requiring reliable performance at elevated temperatures.

P12 seamless pipes are engineered for high-integrity applications where pressure containment is critical. They are extensively used in steam generation systems, including high-pressure boiler tubes and seamless piping for power stations. The uniform structure of seamless P12 pipes ensures consistent creep strength and resistance to thermal fatigue, making them a reliable choice for long-term service.

These pipes offer a practical and budget-friendly option for many high-temperature applications. They are perfectly suited for large-diameter low-pressure steam lines, heat exchanger tubing, and other process systems. Through controlled welding procedures and post-weld heat treatment, we ensure that P12 welded pipes deliver performance and durability comparable to seamless products in their designated service range.

P12 ALLOY STEEL PIPES EQUIVALENT GRADES

| STANDARD | Werkstoff /DIN | Other | Equivalent |

|---|---|---|---|

| A335 Grade P12 | 1.7335 | K11562 | 13CrMo44 |

Specification of Alloy Steel P12 Seamless / Welded Pipes & Tubes

| Specification | Details |

|---|---|

| Specification | ASTM A335 / ASME SA335 |

| Dimensions | ASTM, ASME and API |

| Outside Diameter | 6-2500mm; WT:1-200mm |

| Wall thickness | 0.3mm – 50 mm |

| Size | 1/8″NB TO 30″NB IN |

| Type | Seamless / ERW / Welded / Fabricated Pipes |

| Form | Round, Square, Rectangular, Oval, Hydraulic Etc |

| Length | Single Random, Double Random & Required Length |

| End | Plain End, Beveled End, Treaded |

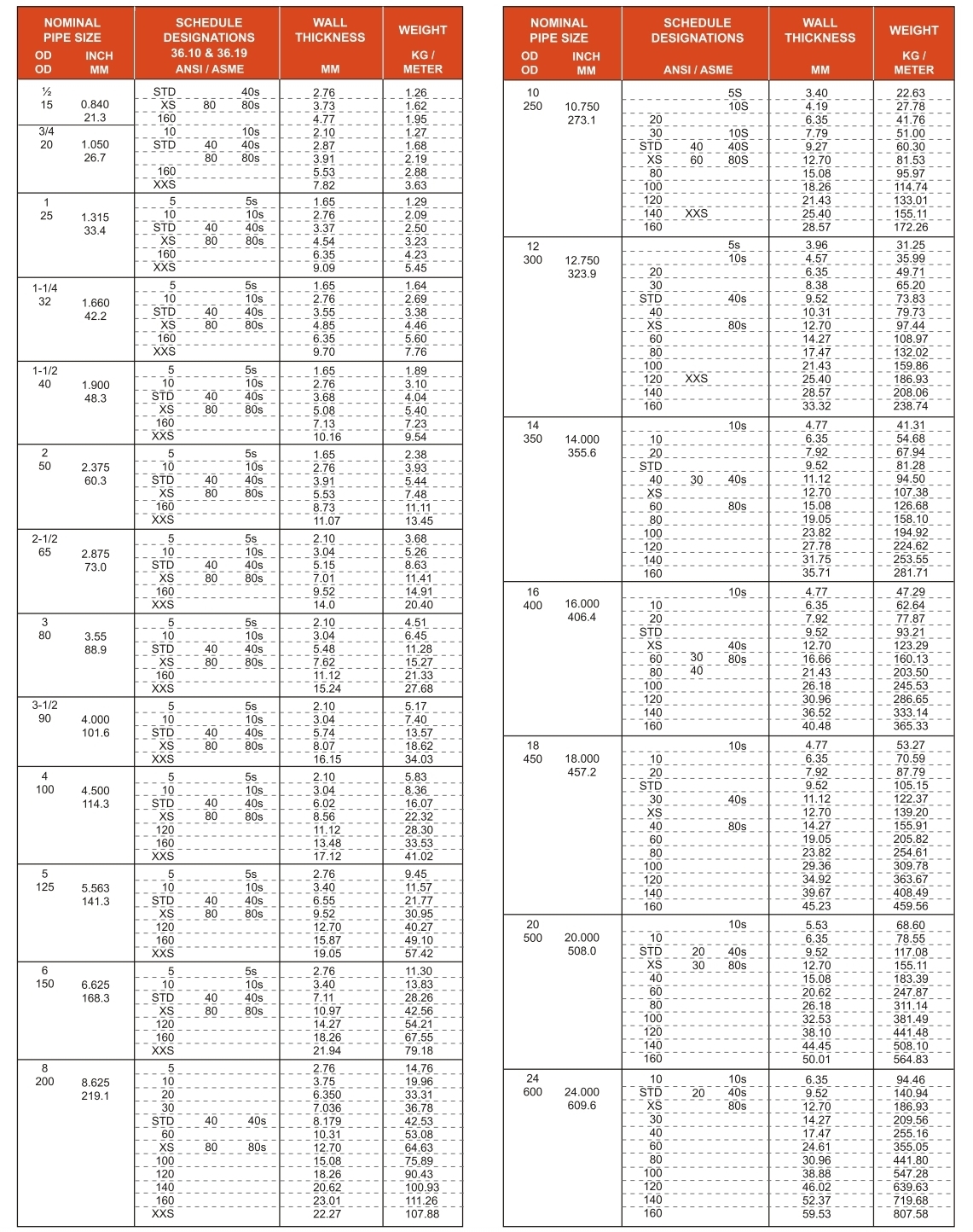

| Schedules | SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules |

| Inspection, Test Reports | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be manufactured on request |

ALLOY STEEL PIPE & TUBES SCHEDULE DIMENSIONS WALL THICKNESS, WT./MTR. (KG)

Click to expand ▼

CHEMICAL COMPOSITION OF ALLOY STEEL P12 SEAMLESS PIPES AND TUBES

| Grade | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

|---|---|---|---|---|---|---|---|

| P12 | 0.05~0.15 | 0.30~0.61 | 0.025 | 0.025 | 0.50~1.00 | 1.00~1.50 | 0.44~0.65 |

MECHANICAL PROPERTIES OF ASME SA335 ALLOY STEEL P12 PIPE

| Grade | Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

|---|---|---|---|

| P12 | 415 min | 220 min | 30 min |

💡 Practical Difference in Use

Use P12 when: requirements are very similar to P11, as it is a closely related 1Cr-0.5Mo alloy with minor compositional differences.

→ Example: Boiler tubes, superheaters, and process piping in power and industrial settings.

Use P12 over other grades when: specific project specifications or historical design practices call for this particular grade. → Example: Replacement parts for existing systems originally built with P12 material.

Uses of Alloy Steel P12 Pipes

P12’s uses are nearly identical to those of P11, making it a common material for high-temperature pressure applications.

- Power Station Boilers: Used in water wall, superheater, and reheater sections.

- Refinery Piping: Employed in fluid catalytic cracking (FCC) units and other high-temperature process lines.

- Industrial Heating Systems: Suitable for high-temperature tubing in various industrial furnace applications.

When to Choose P12 vs. Other Alloy Steels?

The choice between P11 and P12 is often historical or based on specific code allowances. The performance is very similar.

Choose P12 when:

- Replacing like-for-like in an existing P12 system

- Project specifications or available stock favor P12

- Its specific high-temperature properties meet the design requirements for a 1Cr-0.5Mo steel

Consider P11 or P22 when:

- There is flexibility in material selection and another grade offers a cost or performance advantage

- Higher strength (P22) is needed for the application

Request a Quote

Looking for premium Alloy Steel P12 Pipes & Tubes? Contact us today to get the best prices.

Contact Us