What is Alloy Steel P11?

Alloy Steel P11 is a widely used chromium-molybdenum alloy steel with a nominal composition of 1.25% chromium and 0.5% molybdenum. It offers higher strength and better resistance to creep (deformation under long-term stress at high temperatures) compared to carbon steel. P11 is a workhorse grade in power generation and process industries for medium-to-high temperature piping and pressure vessels, providing an excellent balance of performance and cost.

Alloy Steel P11

Chromium (Cr)

Molybdenum (Mo)

Carbon (C)

Manganese (Mn)

Silicon (Si)

Phosphorus (P) Max

Sulfur (S) Max

Iron (Fe)

Types of Alloy Steel P11 Pipes & Tubes

We supply a comprehensive range of Alloy Steel P11 pipes and tubes, available in both seamless and welded configurations, to serve the robust needs of power and process industries.

P11 seamless pipes are the preferred choice for high-pressure steam services, boiler superheater and reheater tubes, and other critical high-temperature applications. Their seamless nature provides inherent strength and reliability, preventing potential failures at weld seams. This makes them essential for power plant main steam lines and other systems where pressure and thermal cycles are a constant challenge.

Offering a cost-effective solution, P11 welded pipes are ideal for large-diameter piping, low-to-medium pressure boiler circuits, and various process industry applications. They are manufactured from plate or coil and undergo full heat treatment to normalize the microstructure, ensuring consistent mechanical properties throughout the pipe, including the welded seam, for dependable service life.

P11 ALLOY STEEL PIPES EQUIVALENT GRADES

| STANDARD | Werkstoff /DIN | Other | Equivalent |

|---|---|---|---|

| A335 Grade P11 | 1.7335 | k11597 | 13CrMo4-5 |

Specification of Alloy Steel P11 Seamless / Welded Pipes & Tubes

| Specification | Details |

|---|---|

| Specification | ASTM A335 / ASME SA335 |

| Dimensions | ASTM, ASME and API |

| Outside Diameter | 6-2500mm; WT:1-200mm |

| Wall thickness | 0.3mm – 50 mm |

| Size | 1/8″NB TO 30″NB IN |

| Type | Seamless / ERW / Welded / Fabricated Pipes |

| Form | Round, Square, Rectangular, Oval, Hydraulic Etc |

| Length | Single Random, Double Random & Required Length |

| End | Plain End, Beveled End, Treaded |

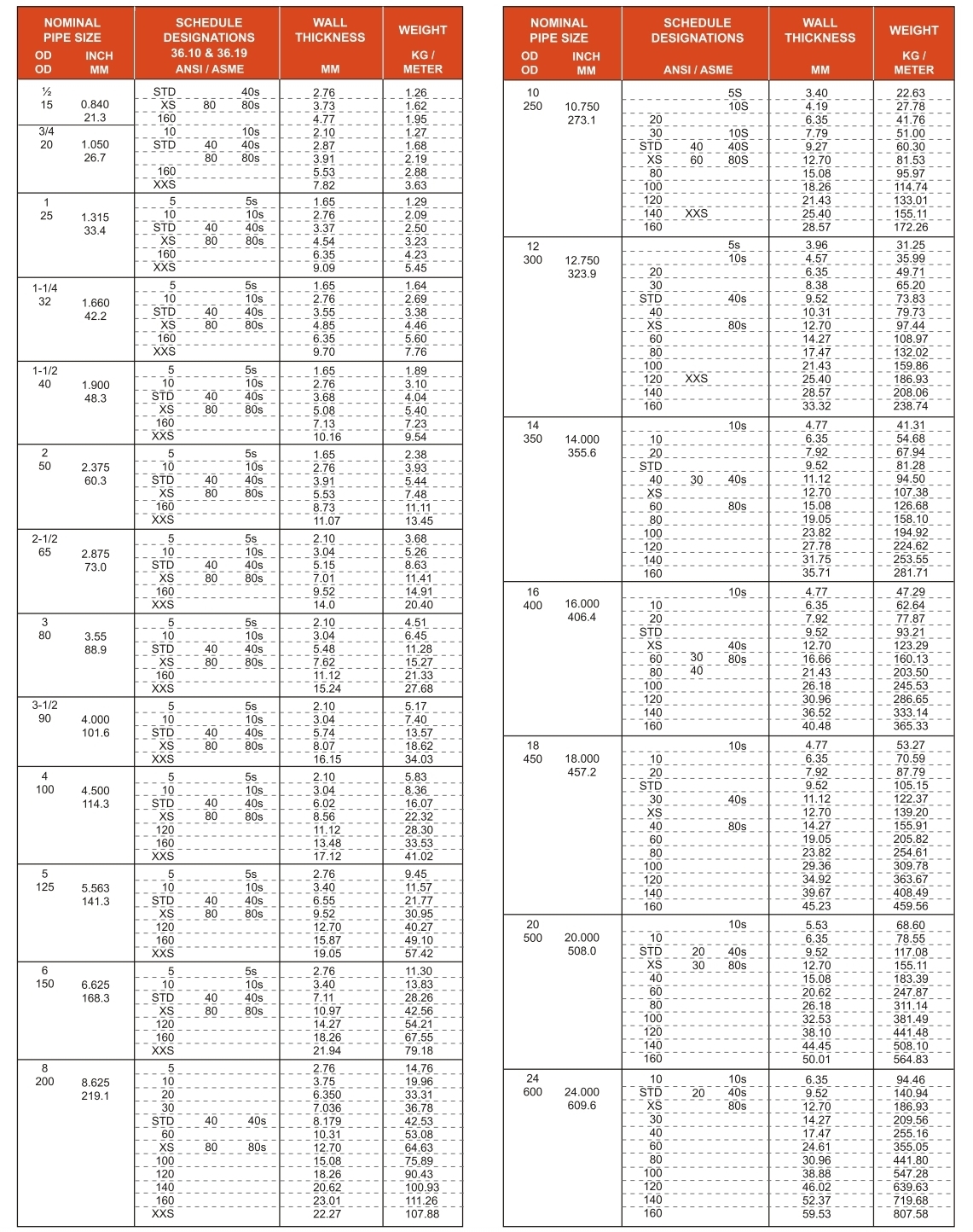

| Schedules | SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules |

| Inspection, Test Reports | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be manufactured on request |

ALLOY STEEL PIPE & TUBES SCHEDULE DIMENSIONS WALL THICKNESS, WT./MTR. (KG)

Click to expand ▼

CHEMICAL COMPOSITION OF ALLOY STEEL P11 SEAMLESS PIPES AND TUBES

| Grade | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

|---|---|---|---|---|---|---|---|

| P11 | 0.05~0.15 | 0.30~0.61 | 0.025 | 0.025 | 0.50~1.00 | 1.00~1.50 | 0.44~0.65 |

MECHANICAL PROPERTIES OF ASME SA335 ALLOY STEEL P11 PIPE

| Grade | Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

|---|---|---|---|

| P11 | 415 min | 220 min | 30 min |

💡 Practical Difference in Use

Use P11 when: you need a good balance of strength, weldability, and resistance to hydrogen attack at temperatures up to ~550°C (1022°F).

→ Example: Boiler superheater tubes, pressure vessels, and process industry piping.

Use P11 over other grades when: its specific combination of 1.25% chromium and 0.5% molybdenum meets the design code requirements for a medium-temperature, high-pressure service. → Example: Power plant boiler tubes and headers in certain temperature ranges.

Uses of Alloy Steel P11 Pipes

P11 (1.25Cr-0.5Mo) is a widely used alloy for high-temperature pressure parts, known for its good creep strength and fabricability.

- Boiler Pressure Parts: Extensively used for superheater and evaporator tubes, as well as headers in power and industrial boilers.

- Process Industry Piping: Common in refineries and chemical plants for high-temperature pipelines carrying oils, gases, and process fluids.

- Heat Exchangers and Pressure Vessels: Used in the fabrication of vessels that operate at elevated temperatures and pressures.

When to Choose P11 vs. Other Alloy Steels?

P11 offers a specific level of performance that makes it a standard choice for many applications, sitting between P5 and P22 in terms of capability.

Choose P11 when:

- The design temperature is typically between 450°C and 550°C (842°F – 1022°F)

- Good weldability and a long history of proven performance are required

- Resistance to hydrogen attack is needed for refinery service

Consider P22 or P91 when:

- Higher strength is needed, allowing for thinner walls (P22 offers better strength than P11; P91 is significantly stronger)

- Operating temperatures are higher, pushing the limits of P11’s creep strength

Request a Quote

Looking for premium Alloy Steel P11 Pipes & Tubes? Contact us today to get the best prices.

Contact Us