What is Alloy Steel P9?

Alloy Steel P9 is a chromium-molybdenum alloy steel similar to P5 but with a higher nominal chromium content of 9%. This higher chromium level provides significantly better resistance to oxidation (scaling) and corrosion, particularly in sulfur-bearing environments. It is specified under ASTM A335 and is designed for high-temperature service, offering a good balance of strength, ductility, and resistance to graphitization.

Alloy Steel P9

Chromium (Cr)

Molybdenum (Mo)

Carbon (C)

Manganese (Mn)

Silicon (Si)

Phosphorus (P) Max

Sulfur (S) Max

Iron (Fe)

Types of Alloy Steel P9 Pipes & Tubes

We manufacture high-quality Alloy Steel P9 pipes and tubes in both seamless and welded forms to meet the demanding requirements of high-temperature and corrosive service applications.

P9 seamless pipes are produced to deliver maximum reliability in high-temperature, high-pressure environments. The seamless construction ensures no weak points, making them ideal for critical applications such as high-temperature steam lines, heater tubes, and piping in petrochemical crackers. Their enhanced oxidation resistance allows for continuous operation at elevated temperatures where lower-grade materials would fail.

These pipes provide an economical alternative for applications that benefit from the superior oxidation resistance of 9% chromium but do not require the highest pressure ratings. They are commonly used in high-temperature process gas lines, convection sections of heaters, and other structural applications. Strict quality control during welding and subsequent heat treatment ensures the integrity of the weldment matches the base metal’s high-temperature properties.

P9 ALLOY STEEL PIPES EQUIVALENT GRADES

| STANDARD | Werkstoff /DIN | Other | Equivalent |

|---|---|---|---|

| A335 Grade P9 | 1.7386 | S50400 | X11CrMo9-1 |

Specification of Alloy Steel P9 Seamless / Welded Pipes & Tubes

| Specification | Details |

|---|---|

| Specification | ASTM A335 / ASME SA335 |

| Dimensions | ASTM, ASME and API |

| Outside Diameter | 6-2500mm; WT:1-200mm |

| Wall thickness | 0.3mm – 50 mm |

| Size | 1/8″NB TO 30″NB IN |

| Type | Seamless / ERW / Welded / Fabricated Pipes |

| Form | Round, Square, Rectangular, Oval, Hydraulic Etc |

| Length | Single Random, Double Random & Required Length |

| End | Plain End, Beveled End, Treaded |

| Schedules | SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules |

| Inspection, Test Reports | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be manufactured on request |

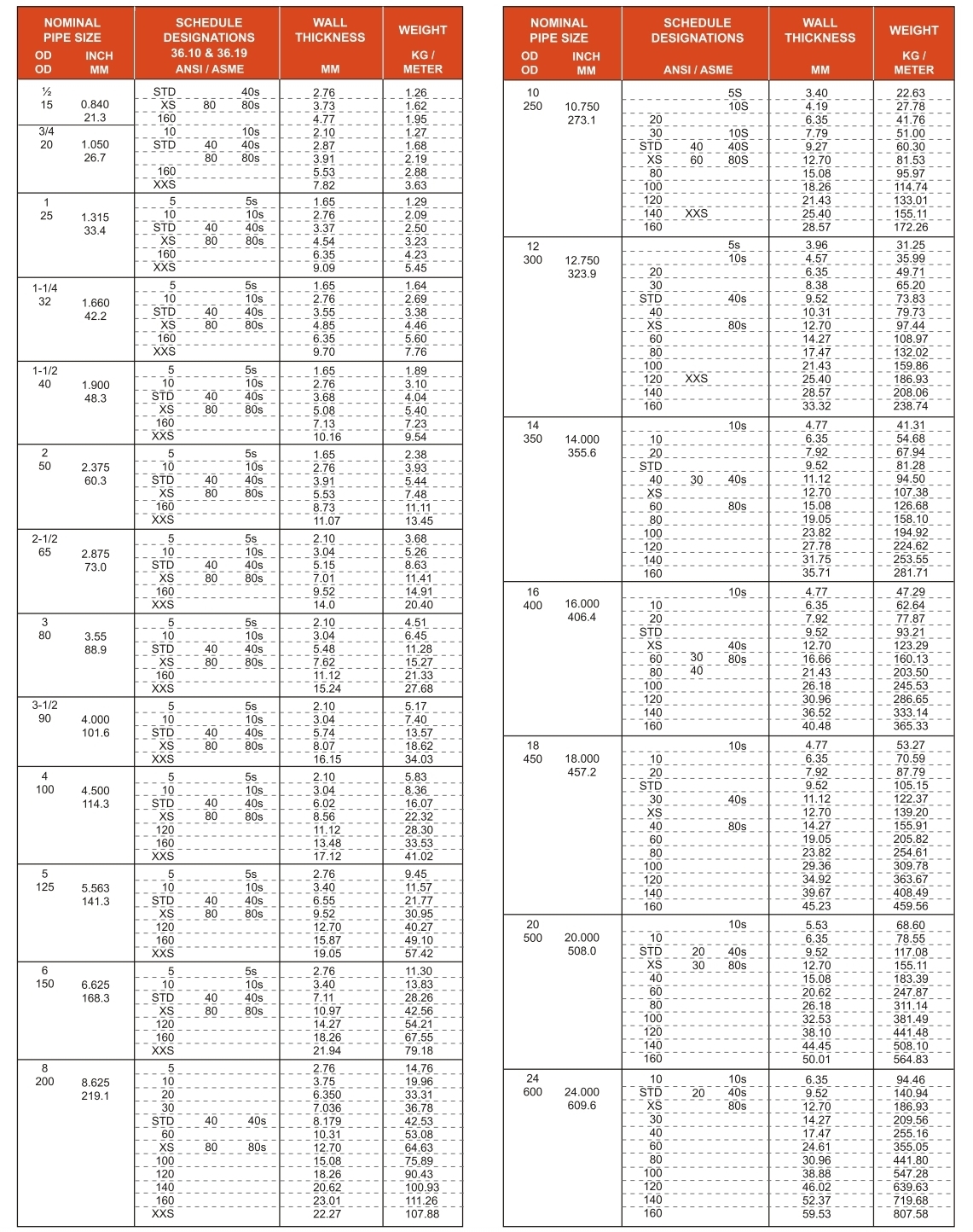

ALLOY STEEL PIPE & TUBES SCHEDULE DIMENSIONS WALL THICKNESS, WT./MTR. (KG)

Click to expand ▼

CHEMICAL COMPOSITION OF ALLOY STEEL P9 SEAMLESS PIPES AND TUBES

| Grade | C | Mn | P | S | Si | Cr | Mo |

|---|---|---|---|---|---|---|---|

| P9 | 0.15max | 0.30-0.60 | 0.025 | 0.025 | 0.25-1.00 | 8.00-10.00 | 0.90-1.10 |

MECHANICAL PROPERTIES OF ASME SA335 ALLOY STEEL P9 PIPE

| Grade | Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

|---|---|---|---|

| P9 | 380 min | 205 min | 30 min |

💡 Practical Difference in Use

Use P9 when: you require higher oxidation resistance than P5, up to about 650°C (1202°F), due to its 9% chromium content.

→ Example: Superheater tubes, reheater tubes, high-temperature heat exchangers.

Use P9 over other grades when: oxidation resistance is a key driver, but the application does not demand the high-temperature strength of more advanced 9% chromium steels like P91. → Example: Older power plant boilers or specific process industry heaters designed for this grade.

Uses of Alloy Steel P9 Pipes

P9 is a 9Cr-1Mo alloy, providing a significant step up in oxidation resistance and elevated temperature strength over lower chromium grades.

- Power Plant Boiler Tubes: Used for superheater and reheater sections in steam boilers where metal temperatures are high.

- High-Temperature Process Piping: Suitable for piping systems in refineries and chemical plants handling hot oils and process streams.

- Heat Treatment Furnace Components: Used for trays, baskets, and internal piping where oxidation resistance is needed.

When to Choose P9 vs. Other Alloy Steels?

P9 was a standard 9% chromium workhorse but has largely been superseded by the superior P91. It is still found in existing installations.

Choose P9 when:

- Maintaining or replacing components in legacy systems originally designed for P9

- Good oxidation resistance up to ~650°C is sufficient for the application

- Cost is a consideration and the lower strength of P9 is acceptable for the design pressure

Consider P91/P92 when:

- New designs require higher allowable stresses, allowing for thinner, lighter-weight components

- Superior creep strength and long-term durability are critical for high-pressure, high-temperature steam

- Operating temperatures push the limits of P9’s capabilities

Choose P9 when:

- Maintaining or replacing components in legacy systems originally designed for P9

- Good oxidation resistance up to ~650°C is sufficient for the application

- Cost is a consideration and the lower strength of P9 is acceptable for the design pressure

Consider P91/P92 when:

- New designs require higher allowable stresses, allowing for thinner, lighter-weight components

- Superior creep strength and long-term durability are critical for high-pressure, high-temperature steam

- Operating temperatures push the limits of P9’s capabilities

Request a Quote

Looking for premium Alloy Steel P9 Pipes & Tubes? Contact us today to get the best prices.

Contact Us