What is Alloy Steel P5?

Alloy Steel P5 is a chromium-molybdenum alloy steel specified in the ASTM A335 standard for seamless ferritic alloy-steel pipe for high-temperature service. With a nominal chromium content of 5%, it offers improved resistance to oxidation and corrosion compared to carbon steel and lower chromium grades. P5 is known for its good strength at elevated temperatures and is widely used in power plants and refineries for high-temperature piping systems.

Alloy Steel P5

Chromium (Cr)

Molybdenum (Mo)

Carbon (C)

Manganese (Mn)

Silicon (Si)

Phosphorus (P) Max

Sulfur (S) Max

Iron (Fe)

Types of Alloy Steel P5 Pipes & Tubes

As a specialized manufacturer, we produce both Alloy Steel P5 seamless and welded pipes & tubes, providing robust solutions for high-temperature and high-pressure applications in critical industries.

Manufactured through a hot extrusion process from a solid billet, P5 seamless pipes offer superior pressure integrity and uniform strength in all directions. The absence of a weld seam makes them indispensable for high-pressure steam lines, refinery transfer lines, and other critical services where failure is not an option. Their homogeneous structure ensures excellent performance under thermal cycling and high-stress conditions.

These pipes are formed from plate or sheet and then welded along a longitudinal seam. P5 welded pipes offer a cost-effective solution for applications with moderate pressures and temperatures, such as certain process piping, boiler tubes, and heat exchangers. Advanced welding and heat treatment techniques ensure the weld zone properties match the base metal, providing reliable performance in corrosive and high-temperature environments.

Specification of Alloy Steel P5 Seamless / Welded Pipes & Tubes

| Specification | Details |

|---|---|

| Specification | ASTM A335 / ASME SA335 |

| Dimensions | ASTM, ASME and API |

| Outside Diameter | 6-2500mm; WT:1-200mm |

| Wall thickness | 0.3mm – 50 mm |

| Size | 1/8″NB TO 30″NB IN |

| Type | Seamless / ERW / Welded / Fabricated Pipes |

| Form | Round, Square, Rectangular, Oval, Hydraulic Etc |

| Length | Single Random, Double Random & Required Length |

| End | Plain End, Beveled End, Treaded |

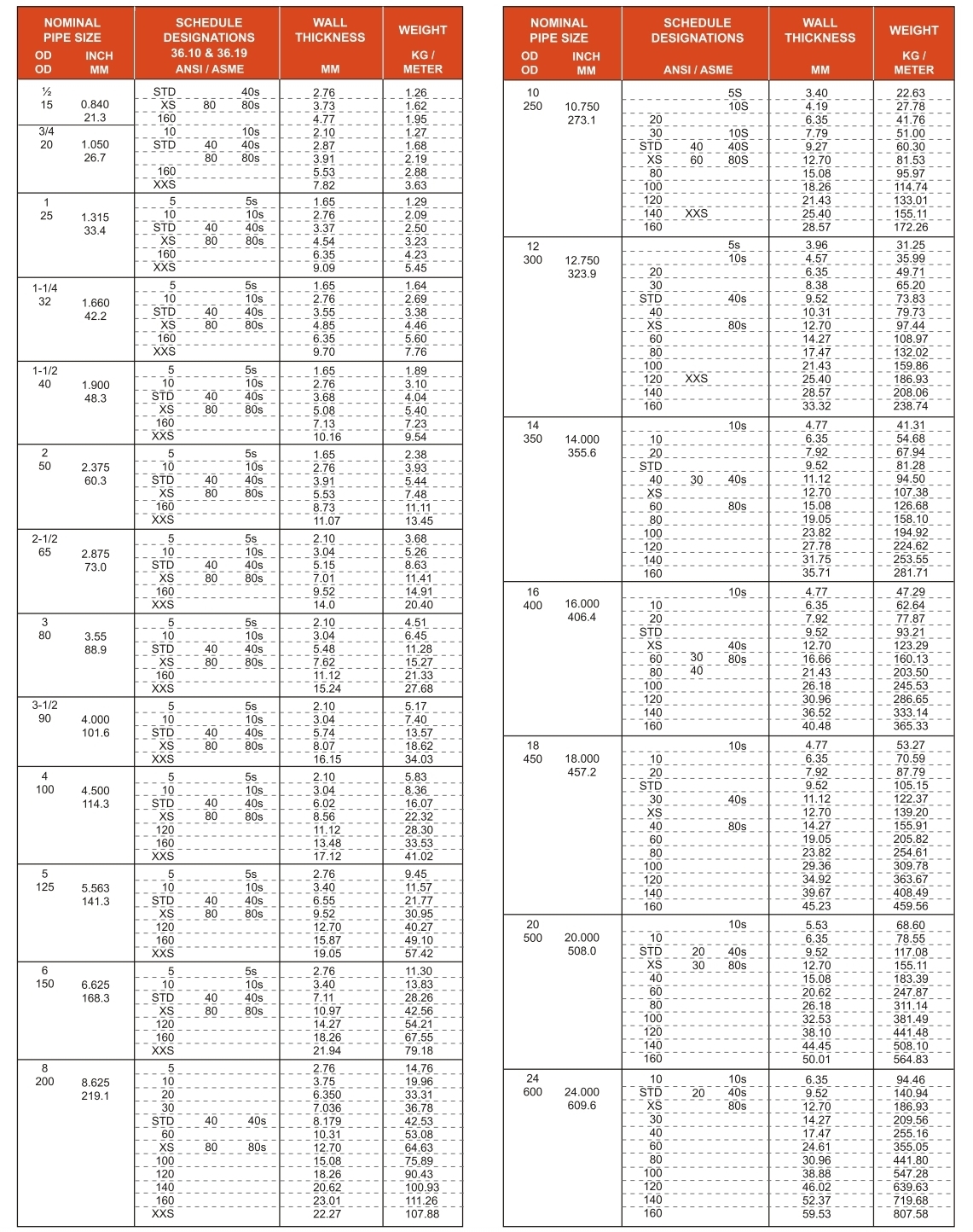

| Schedules | SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules |

| Inspection, Test Reports | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be manufactured on request |

ALLOY STEEL PIPE & TUBES SCHEDULE DIMENSIONS WALL THICKNESS, WT./MTR. (KG)

Click to expand ▼

P5 ALLOY STEEL PIPES EQUIVALENT GRADES

| STANDARD | Werkstoff /DIN | Other | Equivalent |

|---|---|---|---|

| A335 Grade P5 | 1.7362 | K41545 | X11CrMo5 |

CHEMICAL COMPOSITION OF ALLOY STEEL P5 SEAMLESS PIPES AND TUBES

| Grade | C | Mn | P | S | Si | Cr | Mo |

|---|---|---|---|---|---|---|---|

| P5 | 0.15max | 0.30-0.60 | 0.025 | 0.025 | 0.50 max | 4.00-6.00 | 0.45-0.65 |

MECHANICAL PROPERTIES OF ASME SA335 ALLOY STEEL P5 PIPE

| Grade | Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

|---|---|---|---|

| P5 | 415 min | 205 min | 30 min |

💡 Practical Difference in Use

Use P5 when: you need good resistance to oxidation and creep strength at elevated temperatures (up to ~600°C / 1112°F), particularly in hydrogen service.

→ Example: Petrochemical furnace tubes, boiler superheater tubes, heat exchanger tubing.

Use P5 over other grades when: operating conditions are less severe than those requiring higher-chromium alloys like P9 or P11, offering a cost-effective solution for medium-temperature hydrogen service. → Example: Transfer lines and outlet headers in refineries where corrosion resistance is needed but not the highest level.

Uses of Alloy Steel P5 Pipes

The uses are defined by its 5% chromium content, which provides improved oxidation and corrosion resistance compared to carbon steel, along with good elevated temperature strength.

- Petrochemical Furnace Tubes: A primary application, used in refinery heaters and reformers where temperatures are elevated and resistance to hydrogen attack is necessary.

- Boiler Superheater and Reheater Tubes: Used in power station boilers for sections where metal temperatures are sufficiently high to require better oxidation resistance than carbon steel.

- Heat Exchanger Tubing: Employed in high-temperature heat exchangers within chemical and petrochemical plants.

When to Choose P5 vs. Other Alloy Steels?

P5 is a 5Cr-0.5Mo alloy. It sits between carbon steel and higher alloys, offering a balance of performance and cost for specific temperature and corrosion ranges.

Choose P5 when:

- Operating temperatures are in the range of 500°C to 600°C (932°F to 1112°F)

- There is a need for improved resistance to oxidation and hydrogen attack over carbon steel

- The application requires a more economical option than 9% chromium steels

Consider Higher Alloys when:

- Temperatures consistently exceed 600°C (1112°F), requiring P11/P22 or higher

- Superior creep strength is required for high-pressure steam service

- Highly corrosive or oxidizing environments are present that demand stainless steels

Request a Quote

Looking for premium Alloy Steel P5 Pipes & Tubes? Contact us today to get the best prices.

Contact Us