High Quality API 5L LINE Pipes & Tubes

High Quality • Seamless • Welded • Durable & Precise

Get a QuoteAPI 5L Pipes & Tubes

Ratnadeep Steel & Engg. Co. is a leading API 5L line pipe supplier in India, offering a wide range of carbon steel seamless and welded pipes and tubes for oil, gas, and water transmission industries. As a reputed carbon steel pipe manufacturer and exporter, we deliver high-performance API 5L pipes that meet international quality standards and ensure reliability in both onshore and offshore applications. Our product range includes API 5L Grade B, X42, X46, X52, X56, X60, and X65 line pipes, available in customized sizes and thicknesses as per client specifications. The pipes are supplied in different types such as ERW, CDW, fabricated, welded, and seamless, with end finishes including threaded, bevel, plain, or screwed. Length options include single random, double random, and custom lengths, ensuring flexibility for diverse industrial projects. Every API 5L carbon steel pipe undergoes rigorous testing for chemical composition, yield strength, heat treatment, and fracture toughness, with complete certification and traceability. With years of experience and commitment to quality, Ratnadeep Steel & Engg. Co. stands among the most trusted API 5L seamless pipe manufacturers and exporters in India, offering superior products at competitive prices.

Specification of API 5L Line Pipes & Tubes

| Specification | Details |

|---|---|

| API 5L Pipe Specification | API 5L / ISO 3183 Hot Rolled |

| API 5L Pipe Dimension | ASTM, ASME, API |

| API 5L Pipe Grades | API 5L GRADE B PSL1, PSL 2 / API 5L X42 PSL1, PSL 2 / API 5L X46 PSL1, PSL 2 / API 5L X52 PSL1, PSL 2 / API 5L X56 PSL1, PSL 2 / API 5L X60 PSL1, PSL 2 / API 5L X65 PSL1, PSL 2 / X70 PSL1, PSL 2 / API 5L X70 PSL1 / PSL2 / API 5L X80 PSL1, PSL 2 / ISO 3183 L245 PSL1, PSL 2, ISO 3183 L290 PSL1, PSL 2, ISO 3183 L320 PSL1, PSL 2, ISO 3183 L360 PSL1, PSL 2, ISO 3183 L390 PSL1, PSL 2, ISO 3183 L415 PSL1, PSL 2, ISO 3183 L450 PSL1, PSL 2, ISO 3183 L485 PSL1, PSL 2 |

| API 5L Pipe Outer Diameter Size | 3/8″ NB To 30″ NB (Nominal Bore Size) |

| API 5L Pipe Wall Thickness | Schedule 20 To Schedule XXS (Heavier On Request) Up to 250 mm Thickness |

| API 5L Pipe Length | 5 To 7 Meters, 09 To 13 Meters, Single Random Length, Double Random Length And Customize Size |

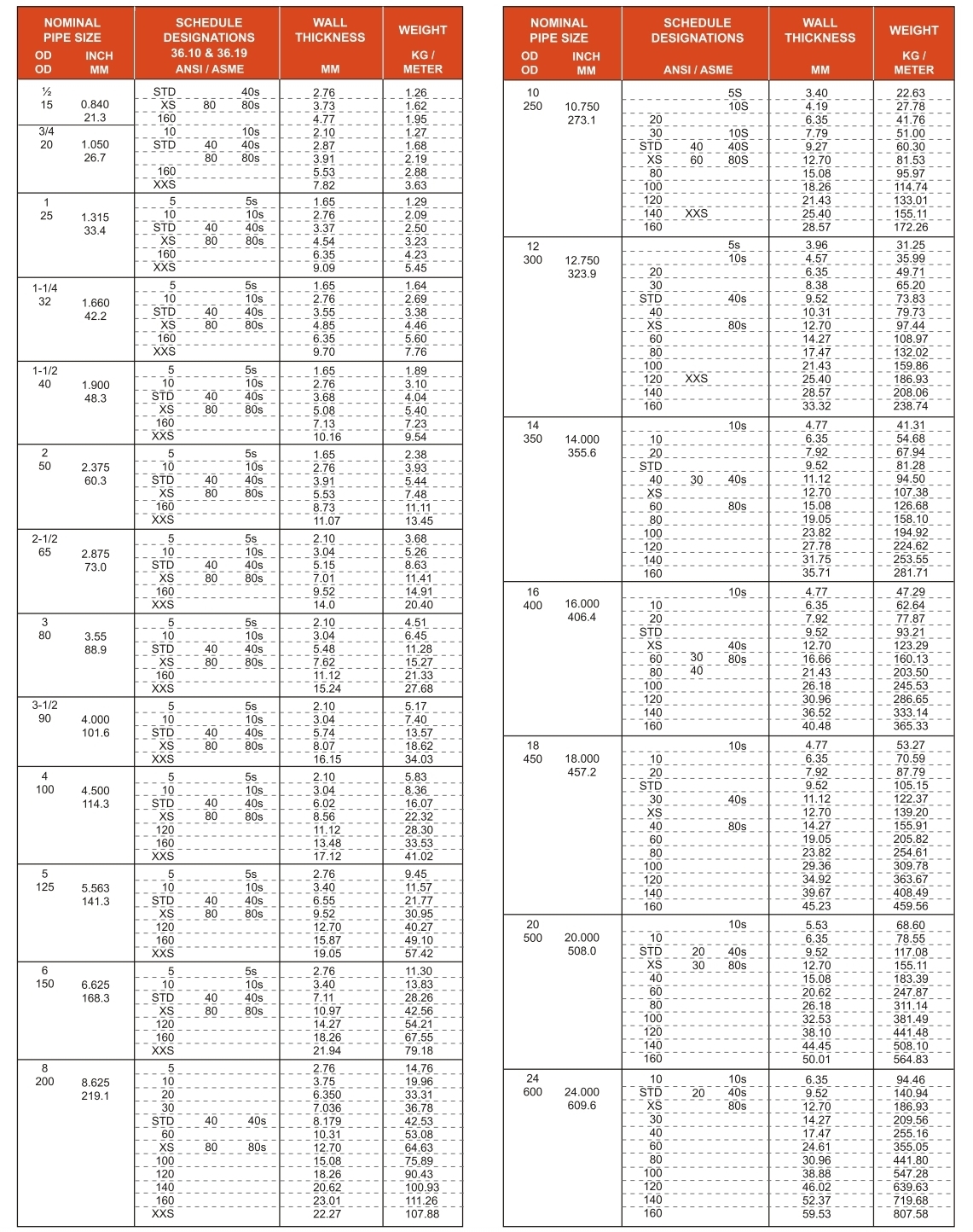

| API 5L Pipe Schedules | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| API 5L Pipe Coating | Epoxy Coating / Colour Paint Coating / 3LPE Coating |

| Surface | Black painting, varnish paint, anti rust oil, hot galvanized, cold galvanized, 3PE |

| API 5L Pipe End | Plain End, Beveled End, Treaded, Coupling |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

CARBON STEEL PIPE & TUBES SCHEDULE DIMENSIONS WALL THICKNESS, WT./MTR. (KG)

Click to expand ▼

API 5L PSL1 LINE PIPE CHEMICAL COMPOSITION AND MECHANICAL PROPERTIES

| GRADE | Chemical Composition | Mechanical Property | ||||||

|---|---|---|---|---|---|---|---|---|

| C (Max) | Mn (Max) | P (Max) | S (Max) | TENSILE (Min) | YIELD (Min) | |||

| Psi X 1000 | Mpa | Psi X 1000 | Mpa | |||||

| A25 CL I | 0.21 | 0.60 | 0.030 | 0.030 | 45 | 310 | 25 | 172 |

| A25 CL II | 0.21 | 0.60 | 0.030 | 0.030 | 45 | 310 | 25 | 172 |

| A | 0.22 | 0.90 | 0.030 | 0.030 | 48 | 335 | 30 | 210 |

| B | 0.28 | 1.20 | 0.030 | 0.030 | 60 | 415 | 35 | 245 |

| X42 | 0.28 | 1.30 | 0.030 | 0.030 | 60 | 415 | 42 | 290 |

| X46 | 0.28 | 1.40 | 0.030 | 0.030 | 63 | 435 | 46 | 320 |

| X52 | 0.28 | 1.40 | 0.030 | 0.030 | 66 | 460 | 52 | 360 |

| X56 | 0.28 | 1.40 | 0.030 | 0.030 | 71 | 490 | 56 | 390 |

| X60 | 0.28 | 1.40 | 0.030 | 0.030 | 75 | 520 | 60 | 415 |

| X65 | 0.28 | 1.45 | 0.030 | 0.030 | 77 | 535 | 65 | 450 |

| X70 | 0.28 | 1.65 | 0.030 | 0.030 | 82 | 570 | 70 | 485 |

API 5L PSL2 LINE PIPE CHEMICAL COMPOSITION AND MECHANICAL PROPERTIES

| GRADE | Chemical Composition | Mechanical Property | C. E. ENERGY | IMPACT ENERGY | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C (Max) | Mn (Max) | P (Max) | S (Max) | Tensile | Yield | PCM | INV | J | FT/LB | |||

| Psi x 1000 | Mpa | Psi x 1000 | Mpa | |||||||||

| B | 0.22 | 1.20 | 0.025 | 0.015 | 60 – 110 | 414 – 758 | 35 – 65 | 241 – 448 | 0.25 | 0.43 | T/L 27/41 | T/L 20/30 |

| X42 | 0.22 | 1.30 | 0.025 | 0.015 | 60 – 110 | 414 – 758 | 42 – 72 | 290 – 496 | 0.25 | 0.43 | T/L 27/41 | T/L 20/30 |

| X46 | 0.22 | 1.40 | 0.025 | 0.015 | 63 – 110 | 434 – 758 | 46 – 76 | 317 – 524 | 0.25 | 0.43 | T/L 27/41 | T/L 20/30 |

| X52 | 0.22 | 1.40 | 0.025 | 0.015 | 66 – 110 | 455 – 758 | 52 – 77 | 359 – 531 | 0.25 | 0.43 | T/L 27/41 | T/L 20/30 |

| X56 | 0.22 | 1.40 | 0.025 | 0.015 | 71 – 110 | 490 – 758 | 56 – 79 | 386 – 544 | 0.25 | 0.43 | T/L 27/41 | T/L 20/30 |

| X60 | 0.22 | 1.40 | 0.025 | 0.015 | 75 – 110 | 517 – 758 | 60 – 82 | 414 – 565 | 0.25 | 0.43 | T/L 27/41 | T/L 20/30 |

| X65 | 0.22 | 1.45 | 0.025 | 0.015 | 77 – 110 | 531 – 758 | 65 – 82 | 448 – 565 | 0.25 | 0.43 | T/L 27/41 | T/L 20/30 |

| X70 | 0.22 | 1.65 | 0.025 | 0.015 | 82 – 110 | 565 – 758 | 70 – 82 | 483 – 565 | 0.25 | 0.43 | T/L 27/41 | T/L 20/30 |

| X80 | 0.22 | 1.90 | 0.025 | 0.015 | 90 – 120 | 621 – 827 | 80 – 102 | 552 – 705 | 0.25 | 0.43 | T/L 27/41 | T/L 20/30 |

API 5L Line Pipe Grades

| API 5L Line Pipe Grades | API 5L Line Pipe Grades |

|---|---|

| API 5L GRADE B Line Pipe | API 5L X56 Line Pipe |

| API 5L X42 Line Pipe | API 5L X60 Line Pipe |

| API 5L X46 Line Pipe | API 5L X65 Line Pipe |

| API 5L X52 Line Pipe | API 5L X70 Line Pipe |

Applications and Uses of API 5L Pipes

API 5L pipes and tubes are widely used for the transportation of oil, gas, water, and petroleum products across long distances. These pipes are specifically designed to perform efficiently under high pressure and harsh environments, making them ideal for critical industrial applications. With excellent strength, corrosion resistance, and dimensional accuracy, API 5L carbon steel pipes ensure smooth and safe fluid transmission in both onshore and offshore projects.

Common Applications:

- Transportation of natural gas, crude oil, and refined petroleum

- Water supply systems and irrigation pipelines

- Structural and mechanical applications in engineering and construction

- Boiler, heat exchanger, and pressure vessel piping

- High-pressure fluid and gas transmission in refineries and petrochemical plants

- Pipeline infrastructure for energy, power, and utility sectors

Industries Using API 5L Pipes:

- Oil & Gas Industry

- Petrochemical and Refinery Plants

- Power Generation Industry

- Offshore and Marine Engineering

- Water Treatment and Desalination Plants

- Construction and Infrastructure Projects

- Mechanical and Process Engineering Sectors

At Ratnadeep Steel & Engg. Co., we supply API 5L seamless and welded line pipes that meet stringent industry standards, ensuring reliable performance and long service life across multiple sectors. Our products are trusted by leading engineering companies and contractors globally for their quality, precision, and cost-effectiveness.

Request a Quote

Looking for premium API 5L Pipes & Tubes? Contact us today to get the best prices.

Contact Us