What is 310S Stainless Steel?

310S stainless steel is a high-temperature austenitic stainless steel grade with excellent oxidation resistance and strength at elevated temperatures. It contains higher chromium and nickel content compared to standard 304/304L grades, making it ideal for applications involving extreme heat and corrosive environments. Its superior performance makes it suitable for various industrial applications where high temperature resistance and corrosion resistance are critical.

310S Stainless Steel

Chromium (Cr)

Nickel (Ni)

Carbon (C) Max

Manganese (Mn) Max

Silicon (Si) Max

Phosphorus (P) Max

Sulfur (S) Max

Iron (Fe)

Types of Stainless Steel 310S Pipes & Tubes

As premier manufacturers in the industry, we specialize in producing both stainless steel 310S seamless pipes & tubes and stainless steel 310S welded pipes & tubes, offering comprehensive solutions for diverse high-temperature industrial requirements.

Manufactured from solid billets through an extrusion process, these pipes deliver superior strength and exceptional pressure resistance at high temperatures. Seamless construction eliminates weld seams, making them the preferred choice for critical high-temperature applications involving furnace parts, heat exchangers, and aggressive corrosive environments where welding integrity is paramount under thermal cycling conditions.

These pipes provide an economical alternative with availability across a broader spectrum of sizes and dimensions while maintaining excellent high-temperature properties. Welded pipes excel in high-temperature structural applications, thermal processing systems, and general corrosive service conditions where reliable welded joints are essential. Their cost-effectiveness makes them ideal for high-temperature projects with budget constraints without compromising oxidation resistance and thermal stability.

Specification of Stainless Steel 310S Seamless & Welded Pipes And Tubes

| Specification | Details |

|---|---|

| Stainless Steel Pipe Specification | ASTM A312, A358 / ASME SA312, SA358 |

| SS Tube Specification | ASTM A213, A269, A249, A511, A554 / ASME SA213, SA269, SA249, SA511, SA554 |

| Pipe Size | 1/8” NB to 24” NB, 1/4” OD to 24” OD sizes |

| Tube Size | 1/2″ OD to 8″ OD |

| Thickness Range | 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Type | Seamless / ERW / Welded / Fabricated Pipes |

| Form | Round, Square, Rectangular, Oval, Hydraulic Etc |

| Length | Single Random, Double Random & Required Length |

| End | Plain End, Beveled End, Threaded |

| End Protection | Plastic Caps |

| Outside Finish | 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Inspection, Test Reports | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be manufactured on request |

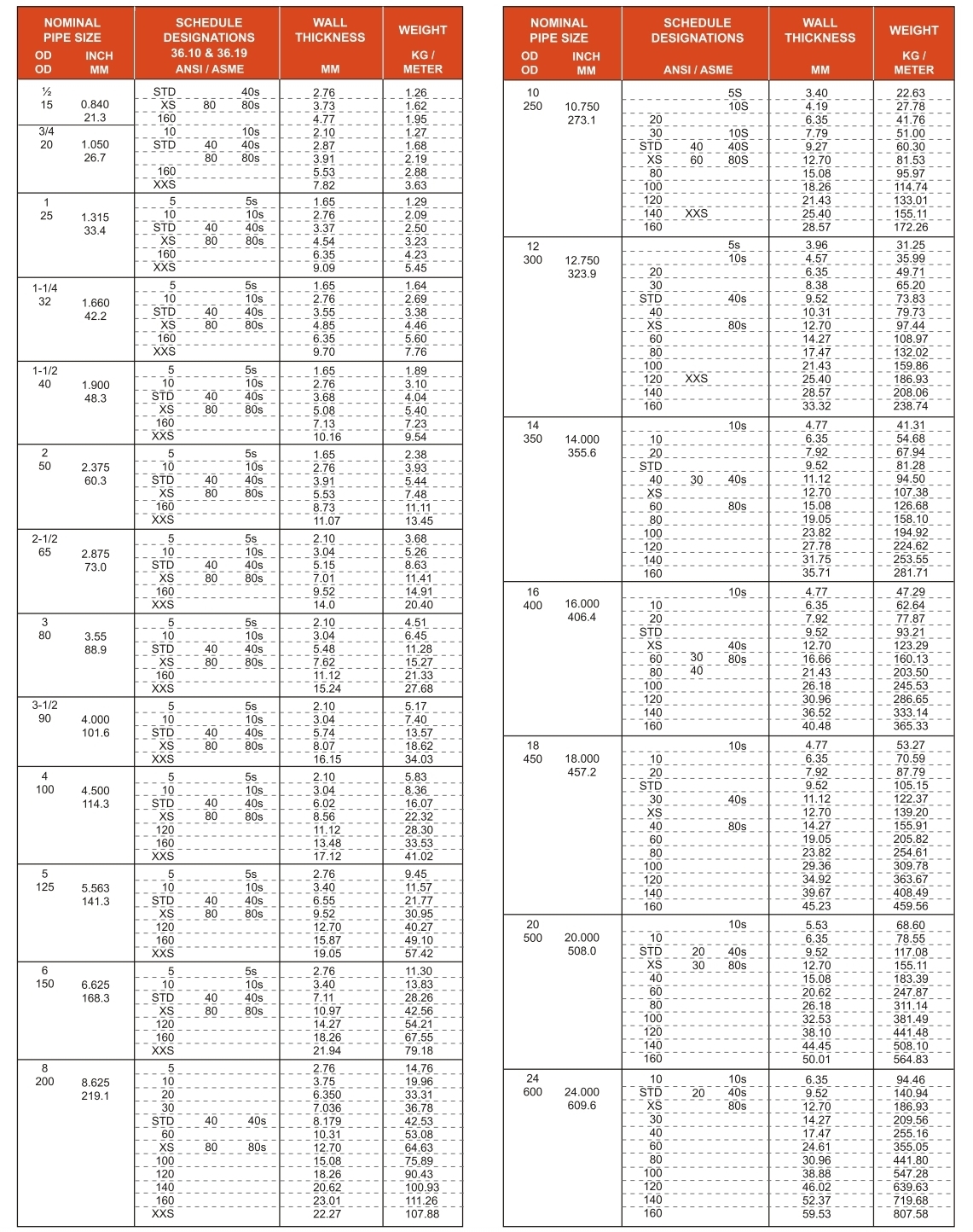

STAINLESS STEEL PIPE & TUBES SCHEDULE DIMENSIONS WALL THICKNESS, WT./MTR. (KG)

Click to expand ▼

Stainless Steel 310S Pipe Dimensions & Weight Chart

| OD (mm) | WT (mm) | NPS (dn) | Schedule | Weight (kg/m) |

|---|---|---|---|---|

| 13.72 | 1.65 | 1/4″ | 10S | 0.50 |

| 13.72 | 2.24 | 1/4″ | 40S | 0.64 |

| 13.72 | 3.02 | 1/4″ | 80S | 0.81 |

| 17.15 | 1.65 | 3/8″ | 10S | 0.64 |

| 17.15 | 2.31 | 3/8″ | 40S | 0.86 |

| 17.15 | 3.20 | 3/8″ | 80S | 1.12 |

| 21.34 | 2.11 | 1/2″ | 10S | 1.02 |

| 21.34 | 2.77 | 1/2″ | 40S | 1.29 |

| 21.34 | 3.73 | 1/2″ | 80S | 1.65 |

| 26.67 | 2.11 | 3/4″ | 10S | 1.30 |

| 26.67 | 2.87 | 3/4″ | 40S | 1.71 |

| 26.67 | 3.91 | 3/4″ | 80S | 2.23 |

| 33.40 | 2.77 | 1″ | 10S | 2.13 |

| 33.40 | 3.38 | 1″ | 40S | 2.54 |

| 33.40 | 4.55 | 1″ | 80S | 3.29 |

| 48.26 | 2.77 | 1.1/2″ | 10S | 3.16 |

| 48.26 | 3.68 | 1.1/2″ | 40S | 4.11 |

| 48.26 | 5.08 | 1.1/2″ | 80S | 5.49 |

| 60.33 | 2.77 | 2″ | 10S | 3.99 |

| 60.33 | 3.91 | 2″ | 40S | 5.52 |

| 60.33 | 5.54 | 2″ | 80S | 7.60 |

| 88.90 | 3.05 | 3″ | 10S | 6.56 |

| 88.90 | 5.49 | 3″ | 40S | 11.47 |

| 88.90 | 7.62 | 3″ | 80S | 15.51 |

Stainless Steel 310S Tube Size Chart

| Wall Thickness (in) | Available Sizes (in) |

|---|---|

| 0.028″ | 1/16″; 1/8″; 3/16″; 1/4″; 5/16″; 3/8″ |

| 0.035″ | 1/8″; 3/16″; 1/4″; 5/16″; 3/8″; 1/2″; 5/8″; 3/4″; 1″; 1-1/4″; 1-1/2″; 2″ |

| 0.049″ | 1/8″; 3/16″; 1/4″; 5/16″; 3/8″; 1/2″; 5/8″; 3/4″; 1″; 1-1/4″; 1-1/2″; 2″ |

| 0.065″ | 3/16″; 1/4″; 5/16″; 3/8″; 1/2″; 5/8″; 3/4″; 1″; 1-1/4″; 1-1/2″; 2″ |

| 0.083″ | 1/4″; 5/16″; 3/8″; 1/2″; 5/8″; 3/4″; 1″; 1-1/4″; 1-1/2″; 2″; 2-1/2″; 3″ |

| 0.095″ | 1/4″; 3/8″; 1/2″; 5/8″; 3/4″; 1″; 1-1/4″; 1-1/2″; 2″; 2-1/2″; 3″ |

| 0.120″ | 1/2″; 5/8″; 3/4″; 1″; 1-1/4″; 1-1/2″; 2″; 2-1/2″; 3″ |

Pressure Ratings for SS 310S Tubing (PSIG)

| OD (in) | WT 0.028″ | WT 0.035″ | WT 0.049″ | WT 0.065″ | WT 0.083″ | WT 0.095″ | WT 0.109″ | WT 0.120″ |

|---|---|---|---|---|---|---|---|---|

| 1/8″ | 7,900 | 10,100 | N/A | N/A | N/A | N/A | N/A | N/A |

| 1/4″ | 3,700 | 5,800 | 7,900 | 9,500 | N/A | N/A | N/A | N/A |

| 5/16″ | N/A | 3,700 | 5,400 | 7,300 | N/A | N/A | N/A | N/A |

| 3/8″ | N/A | 3,100 | 4,400 | 6,100 | N/A | N/A | N/A | N/A |

| 1/2″ | N/A | 2,300 | 3,200 | 4,400 | N/A | N/A | N/A | N/A |

| 3/4″ | N/A | N/A | 2,100 | 2,900 | 3,900 | 4,500 | N/A | N/A |

| 1″ | N/A | N/A | N/A | 2,200 | 2,900 | 3,400 | 3,900 | 4,300 |

Chemical Composition of Stainless Steel 310S Pipes and Tubes

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.08 max |

| Manganese (Mn) | 2.00 max |

| Phosphorus (P) | 0.045 max |

| Sulfur (S) | 0.030 max |

| Silicon (Si) | 1.50 max |

| Chromium (Cr) | 24.00 – 26.00 |

| Nickel (Ni) | 19.00 – 22.00 |

| Nitrogen (N) | 0.10 max |

| Iron (Fe) | Balance |

Mechanical Properties of Stainless Steel 310S Pipes and Tubes

| Grade | Tensile Strength (0.2% Offset) min (MPa) | Yield Strength (ksi) min | Elongation (% in 2″) min | Hardness |

|---|---|---|---|---|

| 310S | 515 | 205 | 40 | Rockwell B (95) max Brinell (217) max |

Physical Properties of Stainless Steel 310S Pipes and Tubes

| Grade | Density (kg/m³) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (μm/m°C) | Thermal Conductivity (W/m.K) | Specific Heat 0-100°C (J/kg.K) | Electrical Resistivity (nΩ.m) |

|---|---|---|---|---|---|---|

| 310S | 7900 | 200 | 14.9 (0-100°C) 16.2 (0-538°C) 17.5 (0-1000°C) |

14.2 (at 100°C) 18.5 (at 500°C) 21.5 (at 900°C) |

500 | 780 |

Equivalent Grades for Stainless Steel 310S Pipes and Tubes

| STANDARD | WERKSTOFF NR. | UNS | JIS | AFNOR | BS | GOST | EN |

|---|---|---|---|---|---|---|---|

| SS310S | 1.4845 | S31008 | SUS310S | Z8CN25-20 | 310S16 | 10Ch23N18 | X8CrNi25-21 |

💡 Practical Difference in Use

Use 310S when: high temperature resistance is the primary requirement, and oxidation resistance is critical.

→ Example: furnace components, heat treatment equipment, radiant tubes, high-temperature process piping.

Use 310S over other grades when: operating temperatures exceed 1000°C (1832°F) and cyclic heating conditions are present. → Example: kiln components, pyrolysis reactors, high-temperature heat exchangers, and thermal processing systems.

Uses of 310S Stainless Steel Pipes

The uses are defined by its exceptional high-temperature strength, outstanding oxidation resistance, and carburization resistance. These pipes are essential for applications involving extreme heat and thermal cycling.

- High-Temperature Process Piping: This is its primary function. It’s used for transporting hot gases, combustion products, and process streams in high-temperature industrial applications up to 1150°C (2100°F).

- Furnace and Heat Treatment Components: 310S pipes are extensively used as radiant tubes, retorts, muffles, and furnace internals where they withstand repeated thermal cycling and extreme temperatures.

- Thermal Processing Systems: With its superior scaling resistance, 310S pipes form critical components in heat treatment furnaces, annealing lines, and high-temperature chemical processes where other grades would rapidly degrade.

When to Choose 310S vs. Other High-Temperature Alloys?

This is a critical question. 310S contains high chromium (25%) and nickel (20%) content, which provides exceptional oxidation resistance and strength at elevated temperatures, far exceeding the capabilities of 304/316 grades.

Choose 310S when:

- Operating temperatures consistently exceed 1000°C (1832°F) with intermittent exposure to 1150°C (2100°F)

- Applications involve cyclic heating and cooling where thermal fatigue resistance is crucial

- Resistance to carburizing and oxidizing atmospheres is required simultaneously

Consider Higher Alloys when:

- Temperatures exceed 1150°C (2100°F) continuously

- Applications involve highly reducing atmospheres or severe carburizing conditions

- Sulfur-containing atmospheres at high temperatures are present

Industries That Use 310S Stainless Steel Pipes

310S stainless steel pipes are essential in industries requiring exceptional high-temperature performance and oxidation resistance. Here are the primary industries that rely on this grade:

This industry is the largest consumer of 310S pipes for furnace components and high-temperature systems.

Uses

Radiant tubes, retorts, muffles, furnace rolls, annealing covers, and heat treatment furnace internals operating up to 1150°C.

Why 310S?

Exceptional oxidation resistance and strength retention at high temperatures. Resists scaling and thermal cycling better than standard austenitic grades.

Critical for high-temperature process units and furnace applications in refineries.

Uses

Furnace tubes, transfer lines, reformer systems, pyrolysis units, and high-temperature process piping in catalytic cracking units.

Why 310S?

Maintains mechanical properties at high temperatures and resists oxidation in process environments containing steam and combustion gases.

Essential for high-temperature components in conventional and nuclear power plants.

Uses

Superheater tubes, boiler components, heat exchanger tubing, and high-temperature steam lines in thermal power stations.

Why 310S?

Excellent creep strength and oxidation resistance at operating temperatures up to 1150°C, ensuring long-term reliability in power generation systems.

Used for high-temperature chemical processes and reactor systems.

Uses

Reactor tubes, high-temperature process piping, catalyst support systems, and thermal oxidizer components in chemical plants.

Why 310S?

Resists oxidation in various chemical atmospheres at elevated temperatures and maintains integrity under thermal stress.

Critical for components exposed to extreme temperatures in glass production.

Uses

Glass tank components, forehearths, regenerators, and glass melting furnace parts exposed to temperatures up to 1150°C.

Why 310S?

Superior resistance to glass corrosion and oxidation at high temperatures. Withstands the corrosive effects of molten glass and combustion atmospheres.

Used in high-temperature processing equipment in cement and lime production.

Uses

Kiln internals, preheater cyclones, calciner components, and high-temperature ducting in cement manufacturing plants.

Why 310S?

Excellent oxidation resistance in alkaline environments and ability to withstand thermal cycling in rotary kiln applications.

Used in high-temperature applications in aircraft and aerospace systems.

Uses

Afterburner components, exhaust systems, heat shield supports, and high-temperature instrumentation in aerospace applications.

Why 310S?

Maintains strength and oxidation resistance at elevated temperatures encountered in jet engines and aerospace thermal systems.

Essential for manufacturing high-temperature industrial heating systems.

Uses

Electric heating elements sheaths, furnace baffles, thermowells, and high-temperature burner components in industrial heating equipment.

Why 310S?

Excellent high-temperature strength and resistance to thermal fatigue, making it ideal for repeated heating and cooling cycles in industrial furnaces.

Request a Quote

Looking for premium 310S Pipes & Tubes? Contact us today to get the best prices.

Contact Us